Robohub.org

Robots on drilling platforms: Austrian-German consortium wins international competition

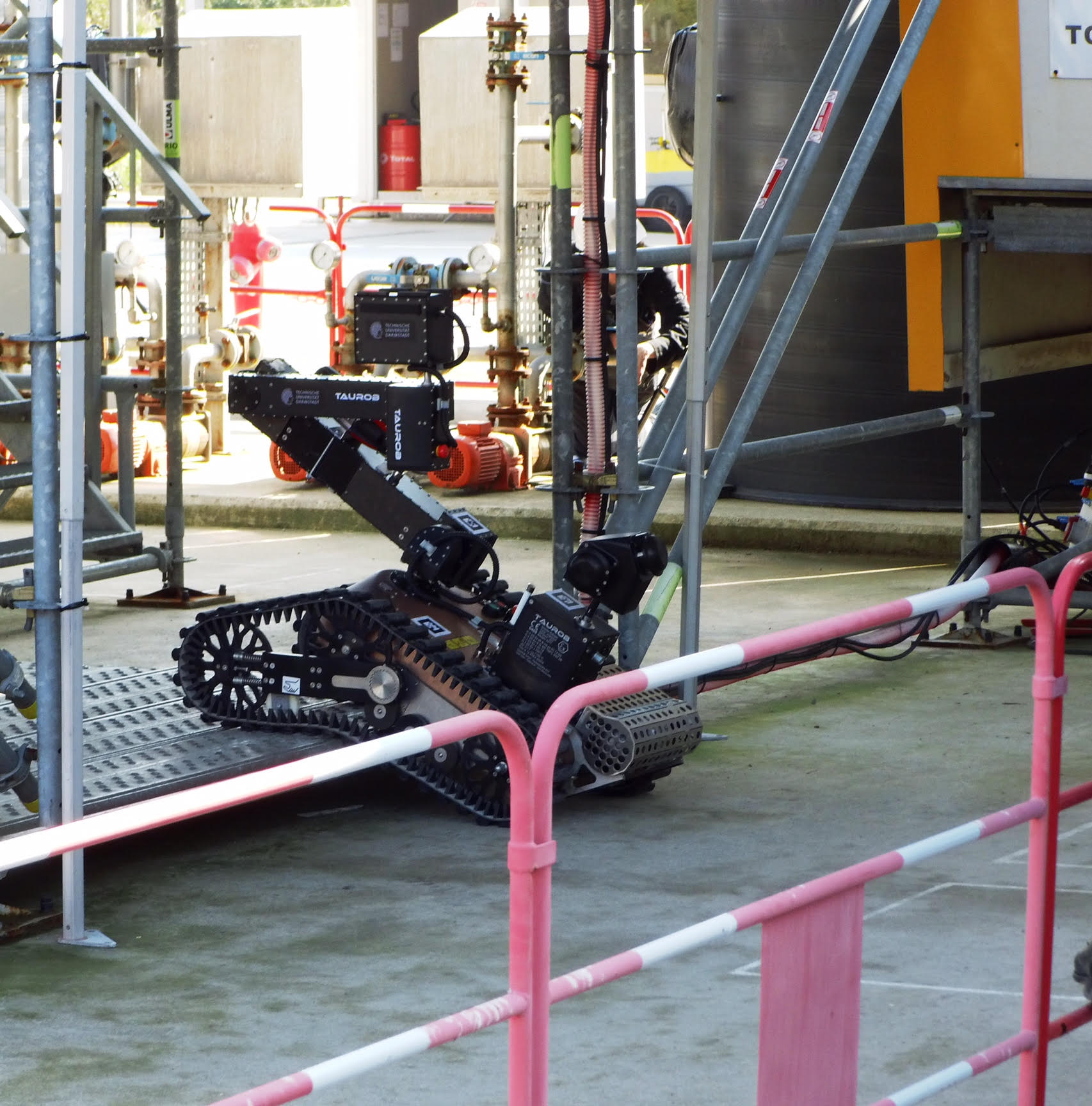

Last week taurob, together with research partner TU Darmstadt, was announced the winner of the ARGOS Challenge, powered by Oil & Gas giant Total S.A.

In a three-year competition, five international teams competed to develop a robot for routine-, inspection- and emergency operations on oil & gas sites. Frequently, gas leaks on oil drilling rigs can cause an increased risk to safety and the environment.

The acronym ARGOS stands for Autonomous Robot for Gas and Oil Sites, which suggests that the robot independently performs assigned tasks. If necessary, an operator can intervene at any time via a satellite-based connection from land and take control of the robot.

The robot, developed by taurob GmbH together with TU Darmstadt, can read pointer instruments, fill level displays as well as valve positions using cameras and laser scanners. It can measure temperatures and gas concentrations, detect abnormal noises, obstacles and people around them, and safely manoeuvre on wet stairs. Adverse environmental conditions such as heavy rain, extreme temperatures and wind speeds do not pose a problem.

“Our robot is also the first fully automated inspection robot in the world that can be used safely in a potentially explosive atmosphere,” says Dr Lukas Silberbauer, who together with his colleague Matthias Biegl, founded the company taurob in 2010. The reason behind it, the robot is already fully ATEX certified so that it doesn’t trigger an explosion while operating in potentially explosive gases.

The Austrian company could capitalize on their knowledge obtaining this certification during their first project: a robot for firefighters.

“When we heard about Total’s contest, we immediately realized that this would be a great opportunity for us,” says Matthias Biegl.

Total has announced that it will use the new robots starting from 2020 on its oil drilling rigs.

The project was supported by FFG (Österreichische Forschungsförderungsgesellschaft) in the context of EUROSTARS (Co-financed by the EU).

tags: c-Exploration-Mining