Robohub.org

Dobot’s robot arm: Industrial precision at low cost

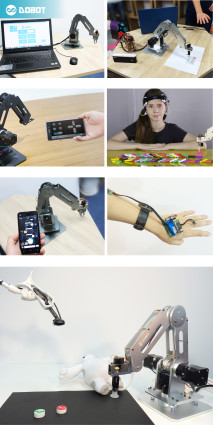

Unsatisfied by the low cost, low precision and poor functionality desktop robotic arms on the market, a group of six hardcore robot makers decided to quit their high-paying industry jobs, and build their own. Their first product is named Dobot: an affordable robotic arm that can actually DO the job, with industrial precision.

Unsatisfied by the low cost, low precision and poor functionality desktop robotic arms on the market, a group of six hardcore robot makers decided to quit their high-paying industry jobs, and build their own. Their first product is named Dobot: an affordable robotic arm that can actually DO the job, with industrial precision.

Fully designed and assembled in China, Dobot, a new desktop, 4-axis, stepper motor, high precision robotic arm has launched its first Kickstarter campaign.

https://youtu.be/UcknDFiCxG4

Feature highlights:

● High mechanical accuracy (0.02mm)

● High repeat precision (0.2mm), 50 times better than uArm

● Stepper motor equipped with high accuracy reducer

● High strength aluminium alloy surface and processed by anodic oxidation treatment

● Mechanical structure assembled by the state of art CNC cutting technology, ensuring its superb agility, stability and durability

● Seven control methods including PC, mobile app, voice, vision, leap motion, geature and EEG (mind control, see demo: https://www.youtube.com/watch?v=RxU7ZhStuPA)

● Easy click-and-drag control interface for beginners and also programmable for advanced makers, using Processing, Arduino, and C/C++ as primary languages

● Affordable price starting from $399, making it affordable for both makers and the general public, Dobot’s design is a good fit for desktop applications.

Tech specifications:

Tech specifications:

● Number of Axes: 4

● Weight: 3kg

● Payload: 500g

● Range: 270 degree rotation

● Position repeatability: 0.2mm

● Material: aluminium alloy 6061

● Controller: Arduino Mega2560

● Communication: UART/Bluetooth

● Power Supply: 12V 5A DC

The team has premiered its prototype at the 2015 Shenzhen Maker Faire, where it received positive feedback from makers, robot experts and open hardware communities.

“The motion is really precise, it’s not just a toy, it can also be used to build stuff,” says the CEO of Arduino, Massimo Banzi.

Dobot was founded in June 2014 by a group of industrial robot engineers based in Shenzhen, China. All the founders acquired extensive industry experience in robotics before joining the team. They have a firm belief that industrial precision robots should be on everyone’s desktop.

tags: c-Consumer-Household, cx-Industrial-Automation, Kickstarter, robotic arm