Robohub.org

Dry vs wet, oil vs grease: Choosing the right lubrication for your robot

In 2008, the Mars Science Laboratory’s launch was delayed, in large part due to issues with lubrication. Lubrication can dramatically impact the performance of your system: improper lubrication can cause your mechanical parts to wear out and fail, and lead to increased power usage and annoying audible sounds. This post looks at the main types of lubrication and where you should use them.

In 2008, the Mars Science Laboratory’s launch was delayed, in large part due to issues with lubrication. Lubrication can dramatically impact the performance of your system: improper lubrication can cause your mechanical parts to wear out and fail, and lead to increased power usage and annoying audible sounds. This post looks at the main types of lubrication and where you should use them.

Tribology – the study of friction, wear, and lubrication – can help us determine the best approach.

Where do you need lubrication (lube) on a robot? The simple answer is: at any joint that moves. In practice this means near actuated joints, bearings, sliders, chains, and in gear boxes. Lube can also be used to reduce rust on metal components.

There are generally two classes of lubrication: wet, and dry (or solid).

Wet lubes stay “wet” while on the part, which is good for operating in wet/humid conditions. The down side is that dirt can stick to it.

Dry lube often goes on wet but then dries on the part it has been applied to. Soil particles do not stick to dry lube, but generally it does not last as long as a wet lube and needs to be reapplied more often. That said, dry lubes tends to stay in place a better than wet lubes. The dry lubes are generally more expensive and have lower performance. Dry lubes are usually required for space and vacuum applications to minimize out-gassing.

Another lubrication decision to make is grease vs oil. This is especially true for motor gearboxes.

Grease adheres better than oil, tends to last longer, and has the added benefit of helping to keep dirt out by acting as a sealant. That said, if a lot of particulate matter gets into the grease, it can compromise the lubricant, so using seals to “hide” the lubricant is a good idea. Grease is thicker than oil when it’s cold, and can be very hard – making it difficult to form an effective coating on the parts. It can take a lot of energy to heat up and/or spin a motor when using grease from a cold start, and running with cold grease can be equivalent to running with no lubrication or running with a solid mass in the way. The result is that a cold motor lubricated with grease can draw a higher current that will drop as the grease starts to move, heat up, and form a light coating on the parts.

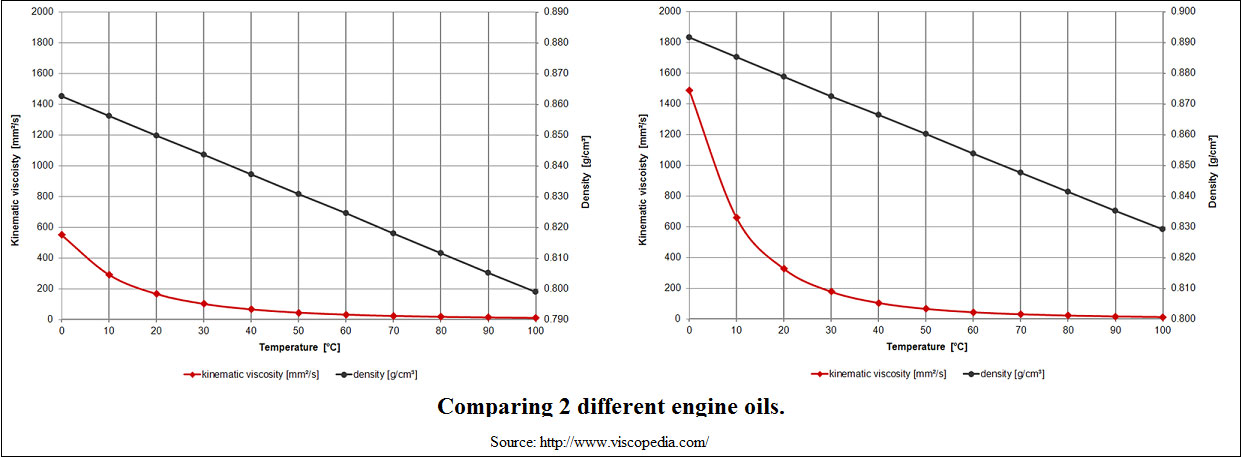

Oil is often a better choice if you need to start from a cold temperature and/or want to reduce your current consumption. There is usually an optimal oil viscosity given a mechanical speed and power input, since the viscosity and lubricating effectiveness changes based on the heating effects. Oil often is used at higher speeds because it has a lower viscous drag than grease. There is a continuum of various “weights” in greases and oils across the viscosity spectrum that you can look at when choosing your lube. Oil is also good where lube needs to be circulated through something (examples are for automated lube systems or for transferring heat for thermal management).

Two plots of different standard engine oil. Showing the viscosity with temperature. (Click for larger image).

People often put too much lube on their system. Usually only a thin coat is needed on your moving parts, and any extra globs are generally a waste. Factory systems that require regular lubrication often use automated systems that apply the lube on a schedule.

The above is general information. There are many different types of oil and grease, each with different characteristics. When you really start getting into the details there are all sorts of material compatibilities, corrosion properties, organic vs. synthetic lubes, viscosities, temperatures, speeds, forces, fretting, water displacement film layers, etc.. that you must take into account. If you are too lazy to select a lubricant (and I often am), purchasing a “general purpose” grease or oil will probably give you medium performance, medium viscosity, and medium just about every other parameter.

It is important to note that lubricants can sometimes be avoided in mechanisms (I know I am contradicting what I have said above). Low friction bushing materials like teflon, nylon, rulon-J, bronze, and even steel on steel, are simple options for mechanisms with low-speed joints that can require no lubrication.

Do you know more about lube? Please leave your comments below.

I would like to thank Nick for helping me edit this and provide information to improve this article.

tags: c-Education-DIY, tutorial