Robohub.org

RoboBee powered by soft muscles

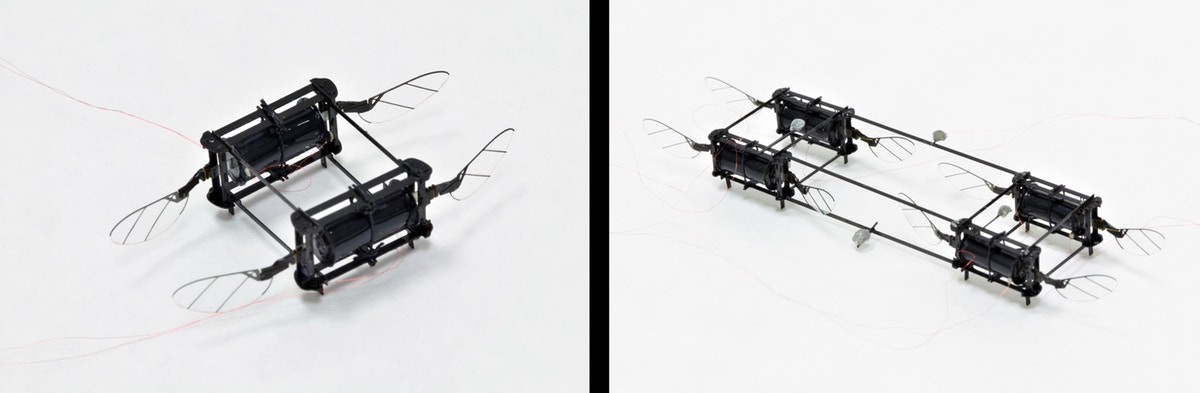

The Wyss Institute’s and SEAS robotics team built different models of the soft actuator powered RoboBee. Shown here is a four-wing, two actuator, and an eight-wing, four-actuator RoboBee model the latter of which being the first soft actuator-powered flying microrobot that is capable of controlled hovering flight. Credit: Harvard Microrobotics Lab/Harvard SEAS

The sight of a RoboBee careening towards a wall or crashing into a glass box may have once triggered panic in the researchers in the Harvard Microrobotics Laboratory at the Harvard John A. Paulson School of Engineering and Applied Science (SEAS), but no more.

Researchers at SEAS and Harvard’s Wyss Institute for Biologically Inspired Engineering have developed a resilient RoboBee powered by soft artificial muscles that can crash into walls, fall onto the floor, and collide with other RoboBees without being damaged. It is the first microrobot powered by soft actuators to achieve controlled flight.

“There has been a big push in the field of microrobotics to make mobile robots out of soft actuators because they are so resilient,” said Yufeng Chen, Ph.D., a former graduate student and postdoctoral fellow at SEAS and first author of the paper. “However, many people in the field have been skeptical that they could be used for flying robots because the power density of those actuators simply hasn’t been high enough and they are notoriously difficult to control. Our actuator has high enough power density and controllability to achieve hovering flight.”

The research is published in Nature.

To solve the problem of power density, the researchers built upon the electrically-driven soft actuators developed in the lab of David Clarke, Ph.D., the Extended Tarr Family Professor of Materials at SEAS. These soft actuators are made using dielectric elastomers, soft materials with good insulating properties that deform when an electric field is applied.

By improving the electrode conductivity, the researchers were able to operate the actuator at 500 Hertz, on par with the rigid actuators used previously in similar robots.

Another challenge when dealing with soft actuators is that the system tends to buckle and become unstable. To solve this challenge, the researchers built a lightweight airframe with a piece of vertical constraining thread to prevent the actuator from buckling.

The soft actuators can be easily assembled and replaced in these small-scale robots. To demonstrate various flight capabilities, the researchers built several different models of the soft actuator-powered RoboBee. A two-wing model could take off from the ground but had no additional control. A four-wing, two-actuator model could fly in a cluttered environment, overcoming multiple collisions in a single flight.

“One advantage of small-scale, low-mass robots is their resilience to external impacts,” said Elizabeth Farrell Helbling, Ph.D., a former graduate student at SEAS and a coauthor on the paper. “The soft actuator provides an additional benefit because it can absorb impact better than traditional actuation strategies. This would come in handy in potential applications such as flying through rubble for search and rescue missions.”

An eight-wing, four-actuator model demonstrated controlled hovering flight, the first for a soft-actuator-powered flying microrobot.

Next, the researchers aim to increase the efficiency of the soft-powered robot, which still lags far behind more traditional flying robots.

“Soft actuators with muscle-like properties and electrical activation represent a grand challenge in robotics,” says Wyss Institute Core Faculty member Robert Wood, Ph.D., who also is the Charles River Professor of Engineering and Applied Sciences in SEAS and senior author of the paper. “If we could engineer high performance artificial muscles, the sky is the limit for what robots we could build.”

Harvard’s Office of Technology Development has protected the intellectual property relating to this project and is exploring commercialization opportunities.

This paper was also co-authored by Huichan Zhao, Jie Mao, Pakpong Chirarattananon, Nak-seung, and Patrick Hyun. It supported in part by the National Science Foundation.