Robohub.org

Japanese Robots: ActiveRobo SAM wants your seat, not your job

If it can be simply installed and removed, if the controls are easy for both veteran and new operators, if together this creates a near-human surrogate, the ActiveRobo SAM could upend the entire R/C car sector. Full-scale R/C cars, that is.

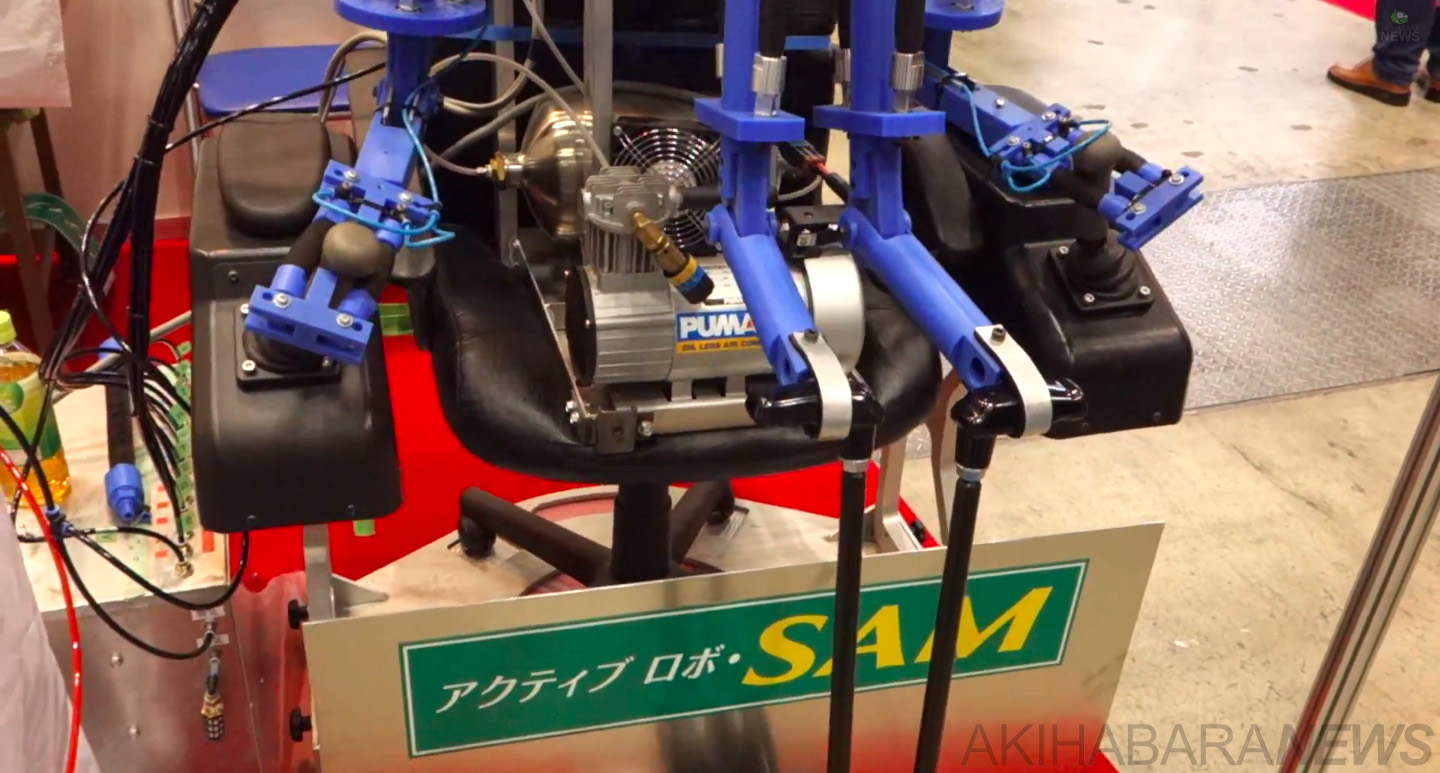

In the final stretch of last October’s Nikkan Kogyo Journal-sponsored Japan Robot Week, as we were just about to pack up the harvest of glossy pamphlets and business cards and join the stream of tired feet returning inland from the Tokyo Big Sight convention center, a bright blue, herky-jerky robot in a chair caught our attention. With maybe 20 minutes of the 3-day event remaining, still humming along on the relative sidelines was Kowa Tech’s ActiveRobo SAM.

Offering little more than a kind of headless, doubled-over skeleton strapped to an office chair, a rep shuffling around with a big remote control, and a TV looping their demo video, the Kowa Tech booth was neither seeking nor receiving a whole lot of attention, and had the floor not been almost empty of attendees we probably would have missed it (yeah, that’s on us). Also, to be fair, they are new to the robo-tradeshow, and, as you’ll see in the video below, an indoor venue really isn’t the place to go all real-world with Kowa Tech’s new product.

Kowa Tech

Counting nearly all of Japan’s major automotive companies as clients, the Tokyo-based engineering firm specializes in custom-built mobile entertainment rigs, emergency response and law enforcement vehicles, medical examination and treatment vehicles, and even some fun stuff like an amphibious tour bus.

L to R: Lighting; Hazardous Fluid Response/Cleanup; Amphibious Bus, Mobile Mammogram – IMAGES: Kowa Tech

While not a robotics company per se, several of the their task- and industry-specific products incorporate hydraulic and pneumatic extenders and manipulators, which, as a platform of expertise, makes a foray into stand-alone robotic systems less a reach and more of a choice.

Simple Utility: Kowa Tech’s ActiveRobo SAM

Pictured above and below (with a brief clip from the Japan Robot Week demo), this collection of appendages in vaguely humanoid form is the business end of a remotely directed robotic vehicle control system. Conceptually, it’s quite simple: joysticks, knobs, and switches manipulated on a custom radio controller direct the flexing and relaxing of pneumatic “artificial muscles” arranged along “arms and legs” that attach to a vehicle’s pedals and levers. When actuated, the robot replicates a human body’s controlling movements.

Kowa Tech claims the system delivers input strength equal to that of human limbs and an overall operational capability 80% that of in-vehicle operation (with gains expected as the system matures). The 3-piece modular robot is weather and vibration-proof, weighs only about 30 kg (66 lbs.), easily installs in under 30 minutes, and can be removed in half that time. Current prototypes are operable from up to 200m, and commercial models are expected to reach 1 kilometer.

Rounded out with video monitoring for an in-vehicle perspective, in theory ActiveRobo SAM is a near-comprehensive surrogate operator. Most of their demos and testing have thus far been limited to excavator and other heavy equipment work, but the company hopes to eventually make the system adaptable to any vehicle.

http://youtu.be/Q5rTp3OViC4

Removable Robot Enables an Entire Fleet

Roboticising and/or remotely controlling heavy equipment and other vehicles is novel neither in concept nor implementation. Full-scale R/C vehicles have long been used in disaster zones where secondary dangers such as collapse, landslide, or toxic exposure remain, and they can minimize risks posed by landmines or improvised explosive devices in conflict zones.

While thoroughly useful and justifiable, extant systems can require complicated internal wiring, additional actuation setup, and some measure of mechatronic retooling, all of which – and this is a fundamental shortcoming – is a very expensive, one-off investment in a single vehicle or piece of machinery. If a job depends on remote operation capability, routine breakdowns and damage or even a simple flat tire could at best delay time-sensitive work and at worst make a desperate situation worse.

If the ActiveRobo SAM meets its promise, it’s no exaggeration to say that it could render a wide swath of currently available solutions obsolete. Whether for individual owners, government agencies, or large-scale rental operations (the latter being quite common in Japan), the potential domestic and international market for a simple, relatively affordable, adaptable and independently replaceable remote operation system is significant and largely untapped.

Development Partners & Incubation Initiatives:

The ActiveRobo SAM system was developed with support from Japan’s Ministry of Land, Infrastructure, Transport & Tourism (MLIT) as part of the Robotic Technology and Systems for Next-Generation Social Infrastructure initiative (次世代社会インフラ用ロボット技術・ロボットシステム) . It is also part of the Robot Town Sagami (さがみロボット産業特区) public relations and robotics education campaign orchestrated by the Kanagawa prefectural government. Additionally, Kowa Tech already has a corporate partner in Caterpillar Japan.

Competition:

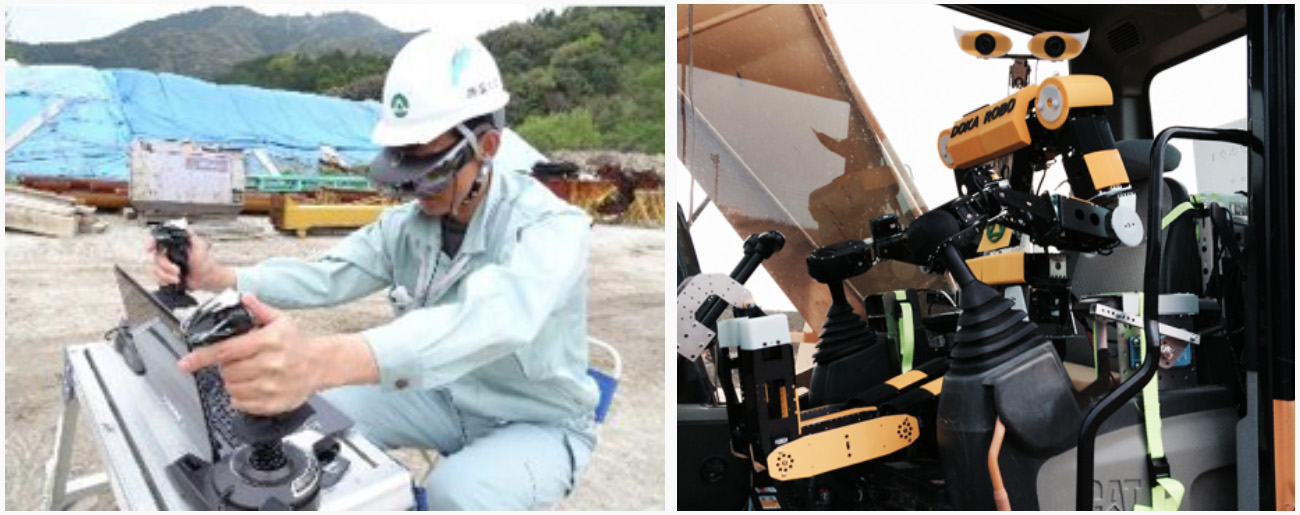

Kowa Tech’s nearest rival here in Japan comes from contracting firm Fujiken’s DOKA ROBO, a similar though more complex and traditionally humanoid telepresence robot that runs on SoftBank subsidiary Asratec’s V-SIDO robot OS. The ambitious, stand-alone humanoid is 150 cm tall, actually “sits” in the operator’s chair, and is expected to offer 3D remote viewing and a more familiar control scheme. The DOKA ROBO project is also part of MLIT’s Next-Gen Robotics Initiative and, as part of the exploration and development track, began its own round of trials and testing just last month.

Purchase:

Kowa Tech is aiming for an April 2015 commercial release, making them considerably further along than any known competitor. If in practice the device can be simply installed and removed, if the control scheme is easy to learn and use for both veteran and new operators, and if all this in concert can in fact produce a near-human surrogate, the ActiveRobo SAM system will not only be a coveted stand-alone product, but also an enticing option for Kowa Tech’s entire line of custom vehicles.

ActiveRobo SAM with Controller MSRP: $40,000-$50,000

Addendum on Jobs

(For the brave, the original version of this article serves up an 800-word diatribe on the disingenuous, sensationalizing, disparagingly incompetent pseudojournalism so often poured over the subject of robotics and employment. Click through at your own risk!)

It’s easy to appreciate how Kowa Tech’s ActiveRobo SAM and similar products prompt the subject of robotics’ impact on industrial employment. In this case, it also brings the issue outside of factories and warehouses where robotics and automation have for decades been changing and/or eliminating human roles.

At first gloss, an operator simply shifting from in-vehicle to proximal operation seems a 1:1 trade-off. However, it’s actually quite illustrative of how changes to or elimination of certain roles often results in a net increase in available jobs, e.g., while the number of excavator operator positions is likely to remain static relative to market demand, the ActiveRobo SAM system creates an entirely independent economic infrastructure.

Should the remote operation of heavy equipment and other vehicles proliferate, a new set of jobs will be created: instructors, programmers, maintenance workers, engineers, distributors, and equipment manufacturers. In the case of a labor shortage, remote operation might even open jobs to those with otherwise disqualifying impairments. Point being, the ActiveRobo SAM opens many doors – and closes zero.

There is no question that robotics and other technological advancements will continue obviating human employment in so-called Dirty, Dangerous, and Demeaning work roles. This steady reshaping of work necessitates new training, new skills, and new ways to do old jobs, but we should remember that this gradual evolution began hundreds of years ago and has again and again proven to be a force for both job growth and human development.

Sure, it’s possible that the rise of robotics will be different, but as of now there’s not a lot of evidence pointing in that direction.

tags: c-Industrial-Automation