Robohub.org

New RoboBee flies, dives, swims, and explodes out the of water

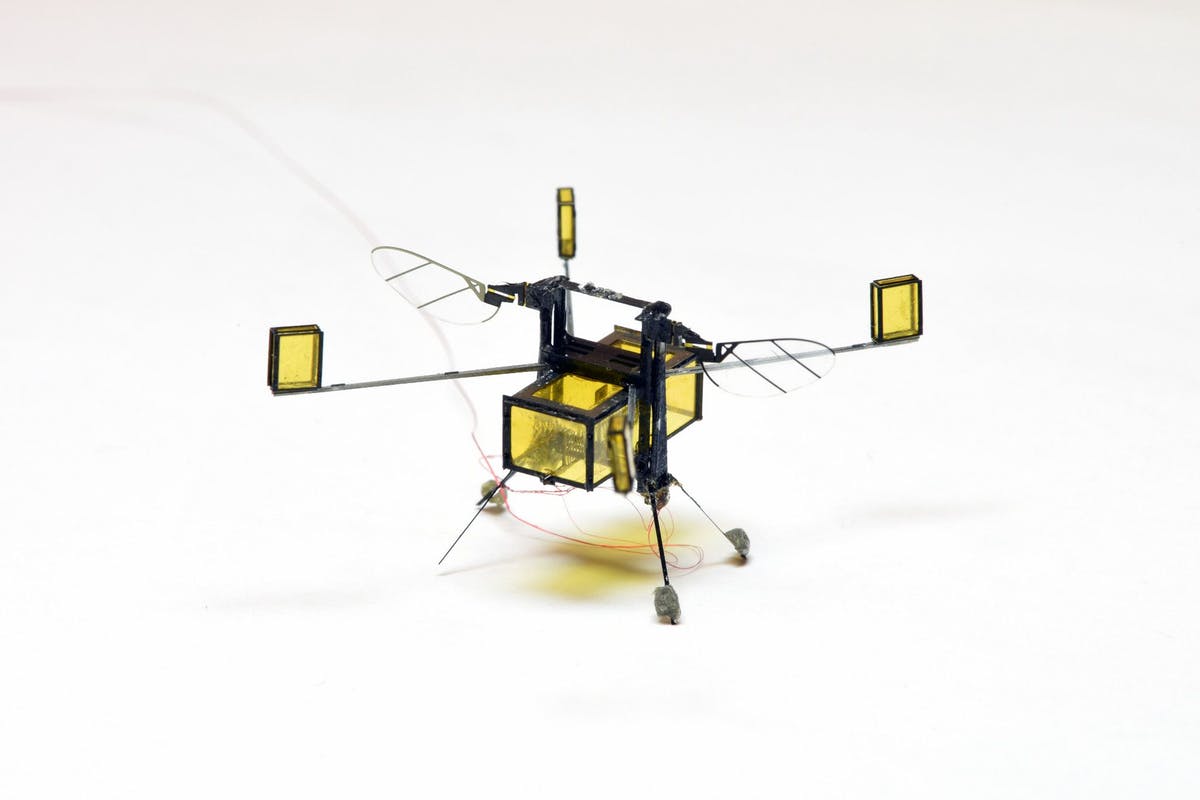

New, hybrid RoboBee can fly, dive into water, swim, propel itself back out of water, and safely land. The RoboBee is retrofitted with four buoyant and a central gas collection chamber. Once the RoboBee swims to the surface, an electrolytic plate in the chamber converts water into oxyhydrogen, a combustible gas fuel. Credit: Wyss Institute at Harvard University

By Leah Burrows

We’ve seen RoboBees that can fly, stick to walls, and dive into water. Now, get ready for a hybrid RoboBee that can fly, dive into water, swim, propel itself back out of water, and safely land.

New floating devices allow this multipurpose air-water microrobot to stabilize on the water’s surface before an internal combustion system ignites to propel it back into the air.

This latest-generation RoboBee, which is 1,000 times lighter than any previous aerial-to-aquatic robot, could be used for numerous applications, from search-and-rescue operations to environmental monitoring and biological studies.

The research is described in Science Robotics. It was led by a team of scientists from the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS).

“This is the first microrobot capable of repeatedly moving in and through complex environments,” says Yufeng Chen, Ph.D., currently a Postdoctoral Fellow at the Wyss Institute who was a graduate student in the Microrobotics Lab at SEAS when the research was conducted and is the first author of the paper. “We designed new mechanisms that allow the vehicle to directly transition from water to air, something that is beyond what nature can achieve in the insect world.”

Designing a millimeter-sized robot that moves in and out of water has numerous challenges. First, water is 1,000 times denser than air, so the robot’s wing flapping speed will vary widely between the two mediums. If the flapping frequency is too low, the RoboBee can’t fly. If it’s too high, the wing will snap off in the water.

By combining theoretical modeling and experimental data, the researchers found the Goldilocks combination of wing size and flapping rate, scaling the design to allow the bee to operate repeatedly in both air and water. Using this multimodal locomotive strategy, the robot to flaps its wings at 220 to 300 hertz in air and nine to 13 hertz in water.

Another major challenge the team had to address: at the millimeter scale, the water’s surface might as well be a brick wall. Surface tension is more than 10 times the weight of the RoboBee and three times its maximum lift. Previous research demonstrated how impact and sharp edges can break the surface tension of water to facilitate the RoboBee’s entry, but the question remained: How does it get back out again?

To solve that problem, the researchers retrofitted the RoboBee with four buoyant outriggers — essentially robotic floaties — and a central gas collection chamber. Once the RoboBee swims to the surface, an electrolytic plate in the chamber converts water into oxyhydrogen, a combustible gas fuel.

“Because the RoboBee has a limited payload capacity, it cannot carry its own fuel, so we had to come up with a creative solution to exploit resources from the environment,” says Elizabeth Farrell Helbling, graduate student in the Microrobotics Lab and co-author of the paper. “Surface tension is something that we have to overcome to get out of the water, but is also a tool that we can utilize during the gas collection process.”

The gas increases the robot’s buoyancy, pushing the wings out of the water, and the floaties stabilize the RoboBee on the water’s surface. From there, a tiny, novel sparker inside the chamber ignites the gas, propelling the RoboBee out of the water. The robot is designed to passively stabilize in air, so that it always lands on its feet.

“By modifying the vehicle design, we are now able to lift more than three times the payload of the previous RoboBee,” says Chen. “This additional payload capacity allowed us to carry the additional devices including the gas chamber, the electrolytic plates, sparker, and buoyant outriggers, bringing the total weight of the hybrid robot to 175 miligrams, about 90mg heavier than previous designs. We hope that our work investigating tradeoffs like weight and surface tension can inspire future multi-functional microrobots – ones that can move on complex terrains and perform a variety of tasks.”

Because of the lack of onboard sensors and limitations in the current motion-tracking system, the RoboBee cannot yet fly immediately upon propulsion out of water but the team hopes to change that in future research.

“The RoboBee represents a platform where forces are different than what we – at human scale – are used to experiencing,” says Wyss Core Faculty Member Robert Wood, Ph.D., who is also the Charles River Professor of Engineering and Applied Sciences at Harvard and senior author of the paper. “While flying the robot feels as if it is treading water; while swimming it feels like it is surrounded by molasses. The force from surface tension feels like an impenetrable wall. These small robots give us the opportunity to explore these non-intuitive phenomena in a very rich way.”

The paper was co-authored by Hongqiang Wang, Ph.D., Postdoctoral Fellow at the Wyss Institute and SEAS; Noah Jafferis, Ph.D., Postdoctoral Fellow at the Wyss Institute; Raphael Zufferey, Postgraduate Researcher at Imperial College, London; Aaron Ong, Mechanical Engineer at the University of California, San Diego and former member of the Microrobotics Lab; Kevin Ma, Ph.D., Postdoctoral Fellow at the Wyss Institute; Nicholas Gravish, Ph.D., Assistant Professor at the University of California, San Diego and former member of the Microrobotics Lab; Pakpong Chirarattananon, Ph.D., Assistant Professor at the City University of Hong Kong and former member of the Microrobotics Lab; and Mirko Kovac, Ph.D., Senior Lecturer at Imperial College, London and former member of the Microrobotics Lab and Wyss Institute. It was supported by the National Science Foundation and the Wyss Institute for Biologically Inspired Engineering.

- PUBLICATION – Science Robotics: A biologically inspired, flapping-wing, hybrid aerial-aquatic microrobot

- WYSS TECHNOLOGY – Autonomous Flying Microrobots (RoboBees)

tags: c-Aerial