Robohub.org

Self-driving trucks are coming — what will that mean?

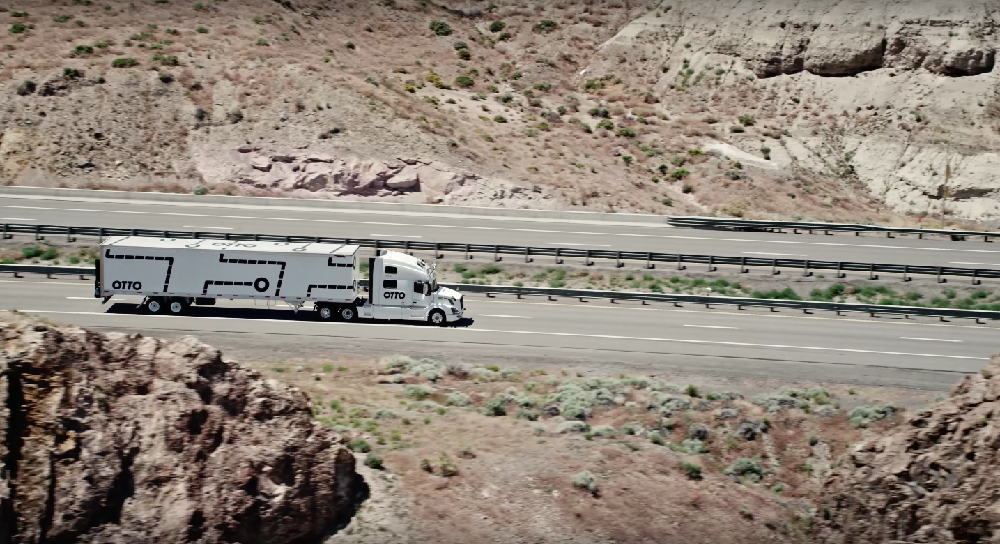

Source: Otto/YouTube

Today sees the un-stealthing of a new company called Otto which plans to build self-driving systems for long haul trucks. The company has been formed by a skilled team, including former members of Google’s car team and people I know well. You can see their opening blog post.

My entire focus on this blog, and the focus of most people in this space, has been on cars, particularly cars capable of unmanned operation and door-to-door service. Most of those not working on that have had their focus on highway cars and autopilots. The highway is a much simpler environment so much easier to engineer, but it operates at higher speeds so the cost of accidents is worse.

That goes doubly true for trucks that are fast, big and massive. At the same time, 99% of truck driving is actually very straightforward — stay in a highway lane, usually the slow one, with no fancy moving about.

https://youtu.be/bK76W1kH4jA

Some companies have done exploration of truck automation. Daimler/Freightliner has been testing trucks in Nevada. Volvo (trucks and cars together) has done truck and platooning experiments, notably the Sartre project some years ago. A recent group of European researchers did a truck demonstration in the Netherlands, leading up to the Declaration of Amsterdam which got government ministers to declare a plan to modify regulations to make self-driving systems legal in Europe. Local company Peloton has gone after the more tractable problem of two-truck platoons with a driver in each truck, aimed primarily at fuel savings and some safety increases.

Safety

While trucks are big, and thus, riskier to automate, they are also risky for humans to drive. Even though truck drivers are professionals who drive all day, there are still around 4,000 killed every year in the USA in truck accidents. More than half of those are truck drivers, but a large number of ordinary road users are also killed. Done well, self-driving trucks will reduce this number. Just as with cars, companies will not release the systems until they believe they can match and beat the safety record of human drivers.

Source: Otto/YouTube

The Economics

Self-driving trucks don’t change the way we move, but they will have a big economic effect on trucking. Driver pay accounts for about 25-35% of the cost of truck operation, but in fact early self-driving won’t take away jobs because there is a serious shortage of truck drivers in the market — companies can’t hire enough of them at the wages they currently pay. It is claimed that there are 50,000 job openings unfilled at the present time. Truck driving is gruelling work, sometimes mind-numbing, and it takes the long haul driver away from home and family for over a week on every long-haul run. It’s not exciting work, and involves long days (11 hours is the legal limit) and a lot of eating and sleeping in truck stops or the cabin of the truck.

Average pay is about 36 cents/mile for a solo trucker on a common route. Alternately, loads that need to move fast are driven by a team of two. They split 50 cents/mile between them, but can drive 22 hours/day — one driver sleeps in the back while the first one takes the wheel. You make less per mile per driver, but you are also paid for the miles you are sleeping or relaxing.

A likely first course is trucks that keep their solo driver who drives up to 11 hours — probably less — and have the software drive the rest. Nonstop team driving speed with just one person. Indeed, that person might be an owner-operator who is paying for the system as a business person, rather than a person losing a job to automation. The human would drive the more complex parts of the route (including heavy traffic) while the system can easily handle the long nights and sparse heartland interstate roads.

The economics get interesting when you can do things that are expensive for human drivers and teams. Aside from operating 22 or more hours/day at a lower cost, certain routes will become practical that were not economic with human drivers, opening up new routes and business models.

The Environment

Computer driven trucks will drive more regularly than humans, effectively driving in “hypermile” style as much as they can. That should save fuel. In addition, while I would not do it at first, the platooning experimented with by Peloton and Sartre does result in fuel savings. Also interesting is the ability to convert trucks to natural gas, which is domestic and burns cleaner (though it still emits CO2.) Automated trucks on fixed routes might be more willing to make this conversion.

Road wear

There is strong potential to reduce the damage to roads (and thus the cost of maintaining them, which is immense and seriously in arrears) thanks to the robotruck. That’s because heavy trucks and big buses cause almost all the road wear today. A surprising rule of thumb is that road damage goes up with the 4th power of the weight per axle. As such an 80,000lb truck with 34,000lb on two sets of 2 axles and 6,000lb on the front axle does around 2,000 times the road damage of a typical car!

An interesting solution is now possible. With fully self-driving trucks (or platoons with nobody in the rear vehicle) you can have two half-weight trucks, which would do 1/8th the damage. 4 1/4 weight trucks would do roughly 1/16th the damage. This is a bit more expensive in fuel and truck wear, though you can get back some of it with platooning. The platoon can space out further on bridges to avoid stressing them.

Right now, trucks pay a higher tax for their high weight, but it’s not 2,000 times what the cars pay. Proper pricing of the externalities of road wear would cause smaller loads to be hauled and save the government a ton of money on road repair. (On the other hand, the standardized 40’ shipping container is so common and useful that there are other challenges here.)

The ability to send smaller loads will enable truck shipping to many destinations where it’s not that economic today. It will also make it easier for the truck to get a load “going back” because robots don’t mind waiting very much. Today, if a truck driver takes a load to a minor location, they may have a long wait before there is a load going back home, and human beings can’t wait quite so easily. (There is always a cost of keeping the tractor idle, but it’s less than the human cost.)

Replacing jobs

Most self-driving teams are working on cars. They do not seek to replace cab drivers, they seek to replace amateur drivers (ie. you.) Of course, they will replace cab drivers, even if that is not the first goal. Cab driver is generally not thought of as a career or something people aspire to — it’s a low skill job people can do to quickly make modest wages. With Uber, people also like setting their own hours; it is a fantastic form of part-time work you can start and stop as you wish, minute-by-minute.

Truck driving is closer to a career, even though it is not a well-loved one for most. There are a bit over 3 million truck drivers in the USA. At first, this technology will not displace many workers, because of the driver shortage. For owner operators it will actually be a boon.

But it would be false to pretend that in the much longer term, this doesn’t reduce the number of people working as career truck drivers. This is one of many of the jobs today that will be modified or replaced by automation in the years to come, and there is no stopping it.

In addition to the jobs, this article paints an more bleak picture concerning those who derive their income from truck drivers, such as Truck Stops, motels and even the towns around them.

Jobs vs. lives

All of this, however, must be put in contrast with the safety benefits. It will be hard to claim that society should work to preserve a job class which kills 4,000 people a year. Probably the only job which kills more is doctor, and they do that in the process of saving lives, not hauling cargo. While some jobs have higher death rates, I suspect only the military, police, doctors and drivers actually kill large numbers of people in the course of doing their jobs. In addition, those who kill while driving often suffer permanent mental scars.

While some will criticise the self-driving trucks as putting the public at risk, once they reach their safety goals, the self-driving trucks will be doing the reverse.

What about rail?

My first reaction looking into this was why don’t we use more rail? Rail is efficient and takes very little human labour per car. To get that efficiency, however, you can’t have service on demand from anywhere to anywhere — you need to group many cars all taking the same trip. In addition, intermodal switches (getting off the train and onto a local truck) are still slow and expensive. In the future, a good mix of rail and on-demand robotrucks combined with automated intermodal switching will provide the most efficient and quick answer for cargo.

Note

I should disclose that while I have no formal relationship with Otto, an advisory role has been discussed which may introduce some bias.

You may also like the coverage in the New York Times by John Markoff.

This article was first published on Brad’s blog. You can read the original article here.

tags: Automotive, autonomous vehicles