Robohub.org

Seven teams from around the world go head-to-head in the Airbus Shopfloor Challenge

The Airbus Shopfloor challengers gearing up for the main event.

Seven teams from around the world go head-to-head in the Airbus Shopfloor Challenge in Stockholm. The challenge is one of the main highlights at the International Conference on Robotics and Automation (ICRA) this week.

With a backlog of almost 7000 aircraft on order, Airbus issued a pressing challenge for the robotics community: how can they improve their manufacturing processes by integrating emerging robotics technologies into their production lines? This week, we’ll see 7 teams present their best solutions and battle it out at the Airbus Shopfloor Challenge. It’s an opportunity for robotics teams to share their innovative ideas with leaders in the field and potentially develop them further with Airbus. Top performing teams will be going home with a cash prize of up to 20,000 euros.

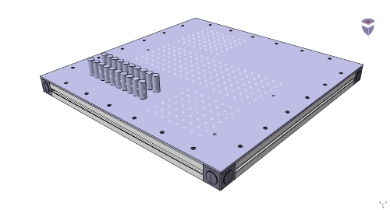

To win, robots attempt to drill 245 holes in a 70cm x 70cm aluminium panel representing an aircraft part. A set of 10 additional points are in a separate area of the panel which is harder to reach. Overall, points will be awarded for each successfully drilled hole, and subtracted for non-compliant holes as well as collisions causing damages to the panel. Solution should also be fully autonomous, lightweight, modular, and open source.

Drilling pattern. Source: Airbus

“We’re drilling over 120 million holes per year for the production of our aircrafts. This still involves a high level of manual drilling.” says Curtis Carson, Head of Research and Technology in the Industrial Strategy and Systems Centre of Competence at Airbus.

And drilling in aircrafts is by no-means easy, due to constraints on space. You basically need to get in there to access hard-to-reach areas. This means much of the drilling happens in non-ergonomic conditions for the workers.

Ideally, the solution is a human-robot collaboration with the robots doing most of the uncomfortable tasks. For the robots to be usable, they will need to be light, and mobile so they can easily access the different parts of the aircraft and interact safely with workers. They will also need to be easy to integrate into the existing production cycle. The way planes are built today relies on decades of legacy work. Drastically disrupting this pipeline could result in years of delay in production.

The modularity and open source requirements enforced in the challenge will further allow solutions to go beyond drilling. If you can easily replace an end effector, or reconfigure a mission, you’re then able to tackle other tasks such as fastening or painting.

How does the competition run?

Each team will compete in a series of 60-minute rounds on Tuesday and Wednesday, with the final confrontation between the top two teams happening on Wednesday. A jury of experts from industry and academia will be judging the competition.

The teams had full reign over the design decisions, with solutions ranging from off-the-shelf robot arms, to custom-made XY platforms. What makes the challenge particularly tricky is the integration of all the components required for the robot to operate robustly. They will need to see drilling locations, plan a trajectory, move in a precise way, and compensate for the extreme vibrations caused by drilling. Each team played to their strengths, with some focussing on control, and others designing hardware.

So without further ado, let’s meet the challengers:

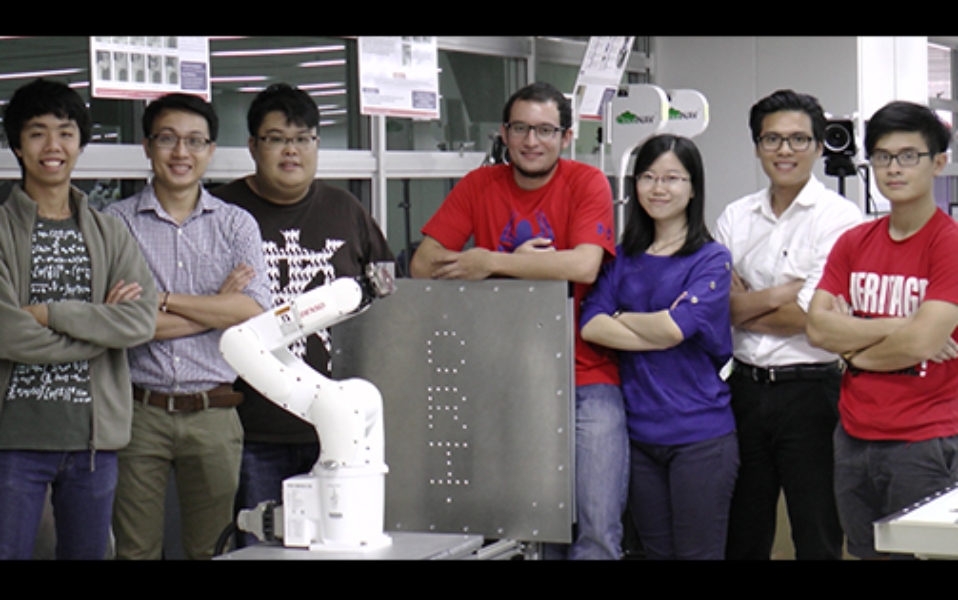

Team CriGroup

Source: Airbus

Team CriGroup is based at the School of Mechanical and Aerospace Engineering, within Nanyang Technological University in Singapore. They are enthusiastic researchers and engineers from Vietnam, Colombia, Thailand, Singapore and China. Their objective is to build robotic systems that benefit workers around the world.

Their solution is a 6 degrees of freedom robot arm produced by Denso and fit with a 3D camera and off-the-shelf driller. “Control was easier for us because it’s our area of expertise. The most challenging aspect was the vision. We were quite new to this and needed to design a custom image processing algorithm to increase the precision of our vision system.

Team Akita Prefectural University

Source: Airbus

Japanese team Akita Prefectural University brings together Associate Professor Takashi Sait, grad student Takahiro Hashi, and undergraduate student Taiki Kudo from the hybrid bio-robotics laboratory. They will be using their experience competing in Robot Battles back at home to build their robot for the Airbus challenge.

Team Sirado

Source: Airbus

Team Sirado brings together 6 researchers from the graduate School of Engineering, Arts et Métiers Lille campus, and 3 experienced industrial representatives from KUKA Systems Aerospace France, and KUKA Automatisme Robotique SAS.

“We developed a solution using the collaborative robot LBR iiwa from KUKA. The robot was chosen for its versatility and to illustrate the potential of lightweight collaborative robotic cells. The electrical drilling effector was specifically designed by KUKA Systems Aerospace France to meet the challenge requirements. A monocular high-resolution camera is used for the detection and localization of the reference hole. During drilling operations, the configuration of the 7-axis robot (1 kinematic redundancy) is optimized to reach a compromise between the rigidity of the robot arm along the drilling axis, and the reachability of the target point.

Team R3

Source: Airbus

R3 is a robotics collective based out of Ryerson University in Ontario, Canada. The team has 20 members from various engineering disciplines including Mechatronics, Electrical Engineering, Computer Science, and Biomedical Sciences.

“Our robotic solution for the Airbus Shopfloor Challenge mechanically aligns a housing to the panel by using a 2-dimensional gantry powered by stepper motors. The housing incorporates a gang drilling technique (7 drill bits) so it is able to drill the pattern quickly and accurately.”

Team Vayu

Source: Airbus

Team Vayu brings together five bachelor students who share their passion for Aerospace. Akash (Team Leader) and Akul are the mechanical experts, Shraddha is the technical writer and finance leader, Siddharth and Sudarshan are coding, microprocessor and sensing experts.

“Our robot is a simple mechanical solution that uses independent linear motion along 3 axes. The coordinates for the drilling are entered into the system beforehand to perform the desired pattern.”

Team Naist

Source: Airbus

Team Naist, from Nara Institute of Science and Technology, Japan includes undergraduate and PhD students, and postdocs from many different countries including Germany, Belgium, Equador, and Mexico. They propose an innovative end effector that stabilizes the workpiece and drill without heavy load-bearing structures, using instead three points of contact that minimize high-frequency vibrations. The solution uses a vision system for precise calibration, and a sensitive robot arm that can operate safely alongside human workers, all while achieving high precision with a low payload.

“Our solution replaces heavy, rigid support structures with a flexible, sensing robot arm. We took inspiration from the way humans stabilize their hands during delicate manipulation tasks, and developed an end effector that connects to the workpiece.” said Felix von Drigalski

Team Bug Eaters

Source: Airbus

The Bug Eaters team from the University of Nebraska-Lincoln, USA is made up of four undergraduate Mechanical and Materials Engineering students. They have all worked in robotics, either as part of classes, research, or work.

“To solve the problem given by Airbus, we wanted to bring new solutions to the table while also demonstrating their viability. To do this, we decided on a planar delta robot, that is, a delta platform with position actuators arranged in a plane to one side of the end effector, rather than the standard triangular arrangement. The delta was chosen because of its ability to remain cost-effective while maintaining the necessary accuracy, as well as its lack of extra unused degrees of freedom. A rotating drill motor was added to the end effector to compactly achieve the additional degree of freedom necessary for the rotating plane of the target panel.” said Alex Drozda.

So stay tuned for two days of competition. You can follow the event live on twitter at #AirbusShopfloorChallenge or below.

#AirbusShopfloorChallenge Tweets

tags: Airbus, Airbus Shopfloor Challenge, c-Events, ICRA16