Robohub.org

Matching technology to value creation: Drones in agriculture

‘Drones in agriculture’ has been a topic hot lately, but is it a real business?

As a former Army UAV platoon leader and a current founder of an aerial data collection start-up, I believe so, but when I first got back from Afghanistan, I did not see how drones could be a big thing in agriculture. WHY? I still do not see how the “pilotless app” makes a decisive difference in most civilian applications. Yet as I expanded my view of a drone to be any flying network node — be it piloted or unpiloted, in the air or in space — I started to see how drone technology could deliver data that creates real value.

Drones may someday perform all kinds of “work” in the field, like spraying or seeding. However, today the product of the drone industry is not drones, it’s data. Two ideas persuaded me that there is a business here. The first is that variability information has real value to growers — it is production control data. The second is that there are places where drone technology allows real data to replace heuristics and estimation in order to drive action.

Agriculture is a very sophisticated business. Even in specialty crops with less automation, the growers are extremely sophisticated and as scientifically inclined as one would expect of managers of multi-million dollar production facilities. Putting production facilities out of doors and using production implements derived from nature only increases the complexity of these operations. In particular, it introduces uncertainty, variation, and risk into the production process. The managers of these operations, who have responsibility for maximizing production, are the customers for this data.

When these managers are trying to squeeze the most production out of a given set of inputs, particularly land and labor, there is a natural cycle of input opportunities. Data only has value if the manager can act on it, and this is where agriculture becomes extremely heterogeneous. At one end of the spectrum you have dry farming of corn, where there might be three or four viable input opportunities (plant, a spray or two, then harvest), most of which are already done automatically — or robotically — on a combine. In high value per acre specialty crops (like vegetables, grapes, or nuts), managers might make over 50 discrete, pre-planned input decisions each year, especially if the crop is deficit irrigated. Even though these crops are in some ways “lower tech” in that they don’t use as much machine automation (such as combines), they do have a much more sophisticated ability to react to variation data. These are where the drone’s fundamental advantages are most likely to be valued.

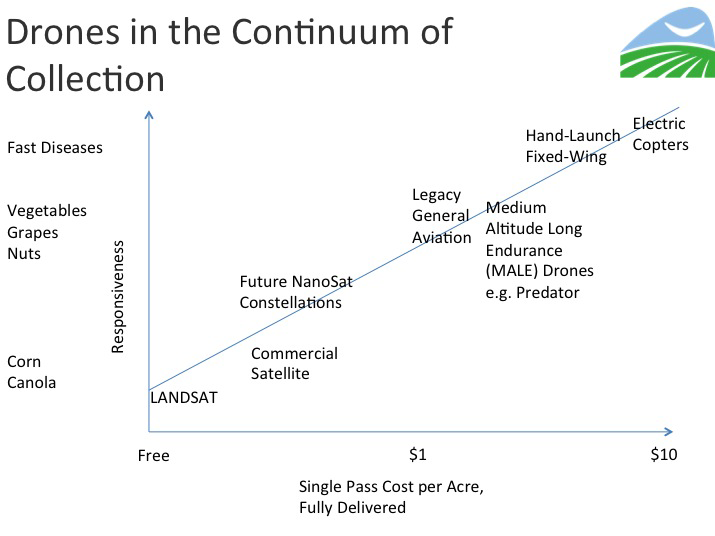

The tradeoff in data collection is a tradeoff between the cost of collection per geographic unit and “responsiveness.” Responsiveness is the degree to which the system can deliver exactly the data needed to make better decisions, exactly when needed, and is a function of many factors including system reliability, resolution, revisit rate, sensor selection, controllability, and ease of deployment.

Drones and other overhead networked systems provide a continuum of data options. At one end you have LANDSAT satellite data, which provides free, 30-meter pixels, un-interpreted data once every 16 days (if you are lucky enough not have clouds). At the other end of the continuum, there are hand-launched drones, which have a high real cost per acre because of their short lifespan and the amount of labor required, but can be launched at anytime and are cheap enough to keep in the back of your truck. In between you have a variety of commercial solutions.

There will always be a tradeoff between cost and responsiveness, but the idea of drones is that electronics will move the efficient frontier in this tradeoff towards more responsiveness at a given cost. The challenge with this access to better data is not to overshoot the mark. It is very expensive to overshoot the required responsiveness for the crop. The trick is match responsiveness to the needs of the manager. This is the task for the commercial drone industry: match responsiveness to the needs of the decision-maker.

As time goes on, every category of platform across the continuum will have to offer more responsiveness for the same money. However, the customer responsiveness needs will not increase unless the managers are also given new mechanisms for taking action. Beyond being used to control fast-spreading crop diseases, I do not know what new markets will open up for drones — perhaps they aren’t in agriculture; the film industry certainly requires even more responsiveness than anything in this field — but it is going to be fun to discover them.

One of the challenges that I would like to lay down to the ground robotics and manipulation communities is to reduce the cost of making an intervention. Until it makes production sense to go out into a cornfield 20 or 30 times per season and take an action to improve growing, there won’t be a need for more responsive information. As interventions become more profitable and crop managers decide to increase the number of interventions, there will be a greater need to automate data collection. Then we can kick off a virtuous cycle of robotic technology.

tags: c-Business-Finance, cx-Aerial, Environment-Agriculture, Mapping-Surveillance, robohub focus on agricultural robotics