Robohub.org

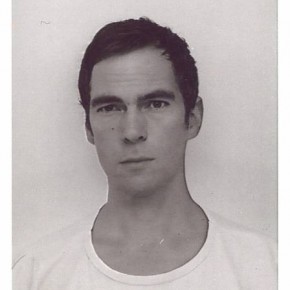

Academic and industry collaboration (Part 3): Interview with Minoru Asada

Established experts in the field of robotics were recently interviewed by a group of scientists from the ECHORD project at Technische Universität München. Motivated by the fact that industry-academia collaborations in robotics are still limited, they wanted to know what makes such collaborations a success, what can be done to avoid common obstacles and what the differences are between collaborations in the US, Europe and Asia. In this 3rd interview of our four-part series, Sascha Griffiths from TUM talked to Minoru Asada, well-known professor at Osaka University, at the occasion of IEEE ICDL-EpiRob conference in San Diego, California.

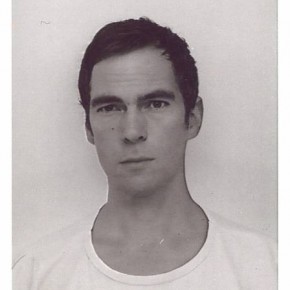

[Sascha Griffiths]

Do you collaborate with industrial partners?

[Minoru Asada]

So far I do not have a direct connection to the industry with my own research. But our department’s curriculum includes projects with two companies.

One is the Daiwa House company. The research topic is the design of an intelligent room. The goal is to control, for example, the air conditioning and the lighting, or to sense the humidity. In order to do that we added face recognition features, recognition of facial expressions, gesture recognition, voice recognition, and so on. So, it is kind of a mixture of that and ambient intelligence.

The second company is Citizen, a clock company. The project was to develop new applications for a watch-like device. We started to design a watch-sized device that measures, for example, the temperature, [the wearer’s] pace, or health related data. We also wanted to include some kind of interaction between the user and this device, for example the ability to understand voice commands. These functions could be included in devices like mobile phones.

Of course, in order to realize the product – especially in the case of the Daiwa House company – we need to do some joint research with them. I myself am the PI, and Hiroshi Ishiguro and another professor are involved as well, and contributed to the project. The other professor does the lighting control by gesture, face, or voice recognition. Maybe, in a couple of years, we will try to realize that as a real project. Not as an entire house, but for certain settings, or for some kind of daily life application. I am not sure when we can realize the product we developed in the project with, maybe in a few years …

In your opinion, how could we minimize time it takes for a product from the development in the lab to being ready for sale?

My idea is that I have my own research agenda: this is fundamental research – and by that I mean development, cognition, and so on. This might seem to be far away from real applications, but I actually do not think that is true. Suppose that the main goal is to reveal the mystery of human development and cognitive functions, for example how a baby can remember something. This involves a lot of steps with lots of different processes. And to do this research we have to design some kind of material, or certain equipment, or a robot. And suppose that this technology can lead to other applications. For example, very soft skin with sensors can also be applied to non-humanoid robots … to furniture or walls, in homes for seniors, to avoid them getting hurt.

There are lots of gaps between even the best ideas and their actual implementation, and closing them is still very far away. In order to fill those gaps, we need a strong team. In our case, for the Daiwa house project for example, we have a collaboration between researchers and industry teams. We have three professors involved, the researchers at Daiwa and some students, altogether more than ten people. These people put a lot of effort into realizing this idea as an actual product.

Is the robotics industry in Japan bigger than in Europe?

We Japanese robot researchers are very proud of our advanced technology. However we are lacking the integration with the real products. The Fukushima power plant was a typical example of this. Many Japanese people expected Japanese robots to be there and to help with rescue operations. But that did not happen. Instead US robots [iRobot’s Packbot and Warrior] were deployed there for the operation. A lot of Japanese people are very disappointed about this, and they are very passionate about this issue.

Another issue is that we have very advanced technology but we are lacking a real – let’s say – verification. For example, 10 or 20 years ago we had a joint research project in Japan: the government spent a lot of money, and companies and researchers designed a [rescue] robot. The ministry then decided that [a rescue-need] situation would not happen and that the robot should focus on inspection only. So, they designed such a rescue robot – but only once. After that they put it in storage and no one used it.

So, we have advanced technology in Japan but we are not good at integrating it in real situations. My idea is to have a site for realistic robot experiments, like a completely new town. There was supposed to be a new town in Osaka. However, last year there were elections for the mayor in Osaka and this new mayor did not support us. There was also the earthquake, and Japanese industry suffered huge losses. For example, Panasonic used to have a research group for robotic applications in a hospital, but they reduced the funding due to a lack of money. These two issues, the earthquake and the new mayor, made me give up on such a site for robot experiments.

In Europe, Paulo Dario proposed RCC – a robot companion for citizens. He was inspired by Japanese robotics but he started to set up these big robot projects that not only involve industry but also research and education. If he receives funding for the RCC, that is going to be a big movement.[note: the RCC project was not funded by the European Commission]

In Japan we have advanced technology but there is no good connection between researchers, the government and industry. Ideally, these three should form a triangle; they should cooperate with each other. But now the government in Japan is just focused on the disaster situation. The industry on the other hand is weakened. Therefore, researchers are losing their connection to the government and industry. Of course the situation you see depends on which industry you take into account: The robot industry in Japan is going through a very hard time right now. It is supposed to only focus on the disaster situation and lacks fundamental research. For fundamental research we need a long term perspective.

In the wake of the earthquake a lot of companies cut their budget for R&D activities. Would you say that this would be a good time for Japanese universities and industry to move closer together?

Right now Japanese companies cannot afford this, as they are focused on the profit. They have suffered from the deficit and are continuously cutting their expenses. Therefore, it is actually not a good time for industry and university connections. I would propose that we focus on topics that will make companies realize that there is some immediate profit to be made. If a research group has a good idea for a device or material that is immediately applicable to the industry, then it might work. But except for such special cases, it is very difficult right now.

If someone has a good idea that should make it into industry, how should researchers communicate such results?

One issue is that Japan is an aging society. In a couple of years one third of the population will be over 65. So, robot applications for the aging society are a social demand – not only for physical but also for mental assistance. There is a lot of potential there. This gives government, the industry and universities an opportunity to collaborate. Safety has top priority here: Physical contact with senior people needs to be improved, and we need time to do research and real-world experiments.

Another issue is entertainment. The origin of the robot is a clockwork-doll. Robots can also be appliances such as door stoppers – any kind of everyday device. The shape is similar to us but it does something strange – and that is kind of fun. In this case you do not need physical interaction – it is not always necessary.

These applications – both for senior citizens and entertainment – are both far away, but they can share some technology. Therefore, a scientist dealing with fundamental research issues can apply their results to different areas. Industry on the other hand needs immediate profit, so they focus on certain topics.

The industry measures success in profit, and researchers’ measure theirs in publications and citations. When these two worlds meet, how would you measure the success of such industry-academia collaboration?

That is a big issue. Even if there is a lot of media coverage, this does not guarantee the success of a product. A typical example for this would be a car. If an automobile company shows a design for a future car and many people like it, the company will introduce it to the market only to realize later that it is “good” but not bought. It’s just to look at.

Therefore, I would propose that we start a good collaboration with some immediate application to the real world and then gradually introduce it to the market. By collaboration, I mean university and industry again. In my opinion the government’s role is to lead this kind of collaboration.

How can increase industry-academia collaboration be increased, and the current problems be overcome?

I mentioned a triangle – the industry, the government and the university or academia. There are still large gaps between these. Therefore, we need someone to connect these, a kind of gatekeeper or producer. Not a researcher but someone with a sense of the market. They should know the demand and need and then determine what kind of product has a big potential.

In Japan we lack the general scientist to promote research. In the US there are general scientists who also are science journalists. These people are necessary. But in Japan science journalists can’t afford a life. I suppose that we need these kind of people to bridge the gap between industry and university. We need people who are not researchers and not in the industry but have a sense of both.

tags: academic/industry partnership, c-Industrial-Automation, collaboration, ECHORD Interview Series, interview, Minoru Asada