The Mitsubishi Research Institute, Inc. (MRI) invites the robotics community to upgrade and to develop a technical catalog of robotic technologies to move and investigate inside nuclear reactor buildings, namely 1) a flight technology to enable access to the top floor of the nuclear reactor building and 2) a technology to move around and conduct investigations under water in a flooded reactor building.

MRI is entrusted by the Agency for Natural Resources and Energy to develop machines and equipment for decommissioning the TEPCO Fukushima Dai-ichi nuclear power plant, which was damaged during the East Japan Earthquake on March 11, 2011.

On December 21, 2011, the Government-TEPCO Council adopted a “Mid-to-Long-Term Roadmap towards the Decommissioning of Fukushima Dai-ichi Nuclear Power Units 1-4”. The roadmap presents a three phase approach to decommission the plant over 40 years.

Japanese decommissioning robots

Sakura

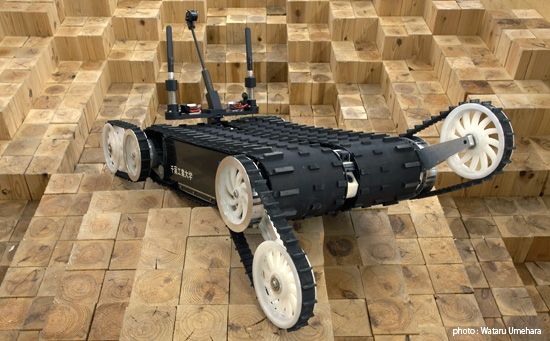

The

Sakura remote-controlled transfer robot, developed by the Chiba Institute of Technology, is the latest version in a line of disaster response robots, and was designed to enter and survey the basements of the damaged Fukushima nuclear reactor buildings. It is specifically designed to collect information in underground facilities, where surveys are considered most difficult. The underground portion of the nuclear reactor building has severe conditions not seen in the above ground portion. There, a robot needs to have high mobility and be able to withstand high radiation levels.

Quince

Quince is a rescue robot designed for CBRNE disasters – situations involving Chemical, Biological, Radiological, Nuclear, and Explosive hazards. It was developed to perform on-site surveys on behalf of humans, such as fire-fighters. Hypothetical disasters include accidents at plants handling toxic substances, leaks of hazardous chemicals from chemical plants, explosions, and acts of terror like the notorious subway sarin incident. Risks are particularly high in enclosed spaces (underground and inside buildings), and expectations are high for robots as they will protect officers from secondary disasters.

Quince surveyed the inside of the Fukushima Dai-ichi nuclear power plant. With some modifications, it was able to photograph the details of the buildings, create radiation dose maps, and sample radioactive materials floating in the air. It has been helping to reduce the radiation dose experienced by on-site workers and to shorten their work period.

Toshiba tetrapod

In November 2012, Toshiba Corporation unveiled a new

tetrapod robot that can carry out investigative and recovery work in locations that are too risky for people to enter, such as the Fukushima power plant.

The new robot integrates a camera and dosimeter and can investigate the condition of nuclear power plants by remote-controlled operation. The multiple joints in its legs are controlled by a dedicated movement algorithm that enables the robot to walk on uneven surfaces, avoid obstacles and climb stairs, securing access to areas that are challenging to reach for wheeled robots or crawlers. The robot also has a folding arm that can release a smaller robot that mounts a second camera. The smaller robot can be positioned to take images of places that are too small for the larger robot to enter. It is connected to the main robot by a cable.

MEISTeR

In December 2012, Mitsubishi Heavy Industries, Ltd. (MHI) unveiled a prototype of the “MEISTeR (Maintenance Equipment Integrated System of Telecontrol Robot),” a two-armed robot to assist recovery work after disasters or severe accidents by performing light-duty tasks in areas inaccessible to humans. By changing its arms’ attachment tools, the robot can perform various tasks such as carrying objects, drilling and opening/closing valves. Going forward, MHI will continue to improve and explore possible applications in crisis management.

tags:

Fukushima,

Japan,

Manipulation

Wolfgang Heller

In November 2012, Toshiba Corporation unveiled a new tetrapod robot that can carry out investigative and recovery work in locations that are too risky for people to enter, such as the Fukushima power plant.

In November 2012, Toshiba Corporation unveiled a new tetrapod robot that can carry out investigative and recovery work in locations that are too risky for people to enter, such as the Fukushima power plant.