Robohub.org

Workshop robots controlled by touch

Factory-in-a-day

by Fintan Burke

The era of robots that can be controlled by designers rather than engineers will enable Europe’s small- and medium-sized enterprises (SMEs) to compete more effectively against often low-wage competitors in other parts of the world.

‘The human can take the tool, or spindle and guide the robot to the parts and (the robot can) memorise some points or some trajectories,’ explained Dr Dragoljub Surdilovic.

He is part of the EU-funded HEPHESTOS project which developed a prototype of a demonstration-controlled robot that can work with large-scale, hard industrial materials such as metals.

The Issue

In 2014 SMEs provided two out of every three jobs in Europe and 58 % of the value of total goods and services.

As well as supporting technology that will benefit SMEs, the EU’s funding programme Horizon 2020 has reserved approximately EUR 3 billion to directly increase the innovation capacity of smaller businesses whose technologies show commercial potential.

SMEs can also now apply directly for funds to implement high-risk and high-potential ideas that will lead to radical changes in how business is done.

It provides more flexibility than traditional manufacturing machines as SMEs can use only one or a few robots to make their products, regardless of how complex it is to manufacture. If a designer sees the robot making a mistake, they can correct it on the fly.

‘With robots we can apply them for different operations,’ said Dr Surdilovic, who is based at the Fraunhofer Institute for Production Systems and Design Technology in Berlin, Germany. ‘The idea for SMEs was how robots can be used to consider the problems of small-batch production.’

After proving that small-batch production is possible with robots, the next step for the researchers is to improve their design by including new and cheaper sensor technology for future robot units.

This kind of simplified, teachable robots will mean SMEs can avoid outsourcing their work, thereby getting more benefit from their innovations.

Hephestos

‘If a company wants to employ a robot today for doing automation … sometimes it takes days, weeks or even mutiple months,’ said Professor Norbert Krüger of the University of Southern Denmark’s Mærsk Mc-Kinney Møller Institute. ‘That means that if you’re looking to produce a few thousand parts, then it is not a good investment.’

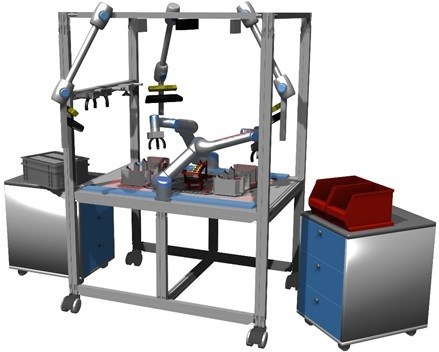

As part of the recently launched RECONCELL project, Prof. Krüger and the other partners in the consortium are working to provide customised robots that can help small businesses quickly set up new production lines, and are taught what to do by demonstration.

‘It’s not only copying, it also needs to understand where the objects are and how they are put together and so on,’ Prof. Krüger said.

Before being deployed in the workshop, the RECONCELL robots rehearse their movements via simulation, fine-tuning their work through virtual trial and error.

‘That’s a key aspect,’ explains Prof Krüger. ‘If you establish a (traditional) robot system, then you do some experiments to find out whether a robot works, this is usually very expensive – particularly when the robot damages something else!’

By the end of the project, in 2018, the aim is to have both the software and hardware at a state such that only few years more are required to arrive at a product for SMEs to build and teach their own production unit.

ReconCell

Same day

While a quick set-up is always the goal with these types of robots, the Factory-in–a-Day project aims to let SMEs start manufacturing on the same day as the robots arrive.

‘Eventually it should be possible to have a small robot installation operational in a day, just like you have your PC operational in a day,’ explained project coordinator Professor Martijn Wisse of Delft University of Technology in the Netherlands.

The project also includes a money-saving element – since the installation period will be dramatically reduced, SMEs can start manufacturing sooner rather than later. This means the time usually spent setting up a production line can now be spent earning an income.

Alongside helping SMEs save time, the project also saves space by including electronic sensors to allow robots and humans to work side-by-side on the floor.

‘If you create a safe robot system that allows the robot to be near a human, or other machines, then you don’t have to create extra safety features that take a lot of time and space,’ explained Prof. Wisse.

Although the project is only a little more than halfway completed, they’ve developed a working prototype of the interface, and were also able to develop the vision software.

It means some companies have already offered to buy the system. ‘It’s not really a matter of getting enough industry involved, it’s more whether we can handle it,’ said Prof. Wisse.

Learn more:

tags: c-Industrial-Automation, cx-Research-Innovation