Robohub.org

OpenBionics prosthetic hands: Open source, affordable, lightweight, anthropomorphic

by Minas Liarokapis, Agisilaos Zisimatos, George Kontoudis, Christoforos Mavrogiannis and Kostas Kyriakopoulos

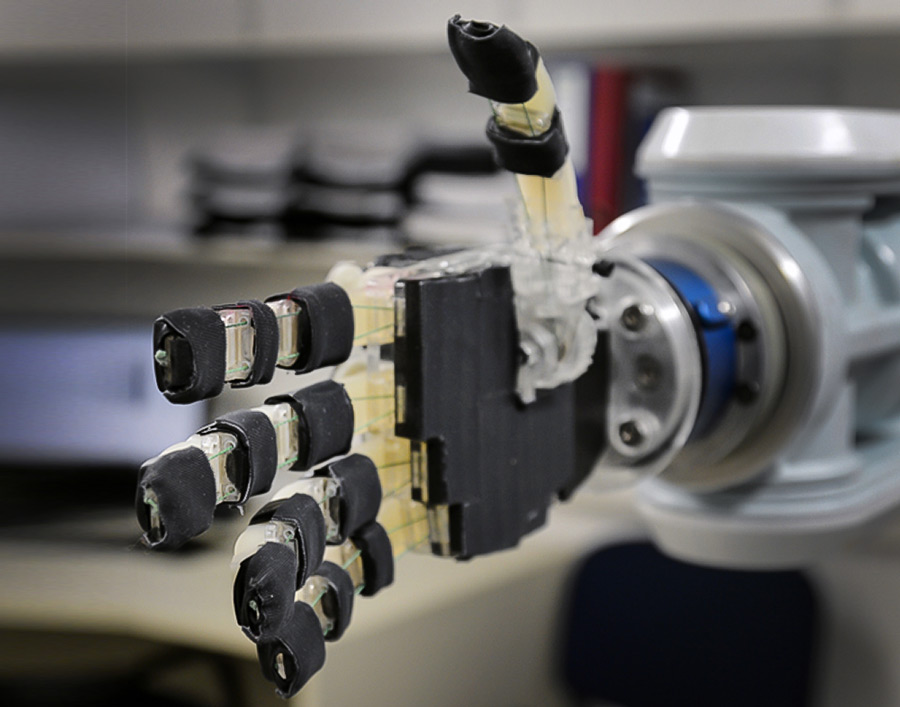

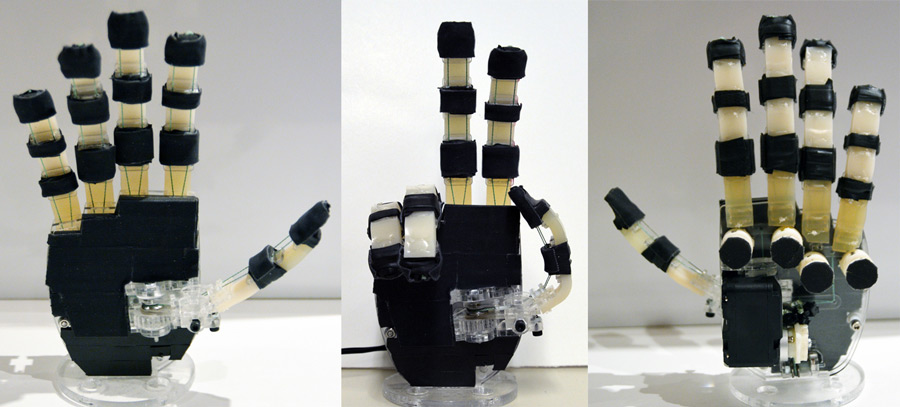

Fig. 1. The OpenBionics prosthetic hand.

OpenΒionics is an open-source initiative for the development of affordable, light-weight, modular robot hands and prosthetic devices, and can be easily reproduced using off-the-shelf materials.

$200 robotic prosthetic handMost current prosthetic hands cost tens of thousands of US dollars. The OpenBionics initiative presents a new open-source design for highly functional, affordable prosthetic hands. The proposed hands (see Fig. 1) cost less than $200, weigh less than 300g and can be easily fabricated with off-the-shelf materials and rapid prototyping techniques. A novel selectively lockable differential mechanism (based on the whiffletree) allows the user to block the motion of each finger independently, and facilitates the execution of 144 different postures with only one motor. To our knowledge this is the most affordable and light-weight prosthetic hand ever built. The design is based on parametric models of hand anthropometry studies, so it can easily be personalized to specific patients. Anyone interested should fill out the appropriate web-form, providing the desired specifications (hand type: left or right, hand length and breadth) and they will receive the personalized design via email.

Nowadays most amputees express their disappointment for: 1) the large cost of buying and maintaining a prosthesis, 2) the increased weight of the device and 3) the difficulties they face with repairs [1]. Moreover the fear of damaging the prosthesis leads most of the amputees to avoid using them in everyday life tasks and use instead simple hooks or grippers. On the other hand, when the amputees are involved in the selection and preparation of the prosthesis (e.g., replication of an open-source design), the likelihood of prosthesis acceptance is increased 8 times. These findings confirm that what amputees need is a highly functional, personalized, affordable and light-weight prosthesis that can be easily developed and repaired.

The OpenBionics initiative has developed and freely distributed an open-source design for creating anthropomorphic, under-actuated prosthetic hands of low complexity and cost. Our hands use a novel differential mechanism (a variation of the whiffletree or “seesaw mechanism” [2]) that blocks the motion of each finger, allowing the user to select between multiple grasping postures and gestures with only one motor. Human-likeness of both robot structure and motion is achieved by employing an index of anthropomorphism in the design process [3] that uses parametric models derived from hand anthropometry studies [4]. The proposed hands can be easily reproduced with off-the-shelf materials and can be fabricated with rapid prototyping techniques.

Hand Design

Robot Fingers – In our design, anthropomorphism is reflected in two specific design choices: 1) the use of an anthropomorphic kinematic model [3] and 2) the use of a bio-inspired finger actuation and transmission system. The bio-inspired finger design structurally reproduces the flexion movements of the human hand with tendons driven through low-friction tubes and the extension using elastomer materials. The backbone of the finger can be constructed with Plexiglas (acrylic) or ABS, and the flexure joints with silicone or polyurethane sheets.

Thumb Mechanism – For the thumb we use a selectively lockable, toothed mechanism that can implement 9 different opposition configurations. The mechanism substitutes the three Degrees of Freedom (DoF) that implement the human thumb opposition with only one rotational DoF and is completely stiff when it is locked, thus it is not affected by torsional forces inherent in dynamic or unstructured environments. A separate tendon routing system is used for the thumb, and the thumb tendon is terminated to a separate servo pulley.

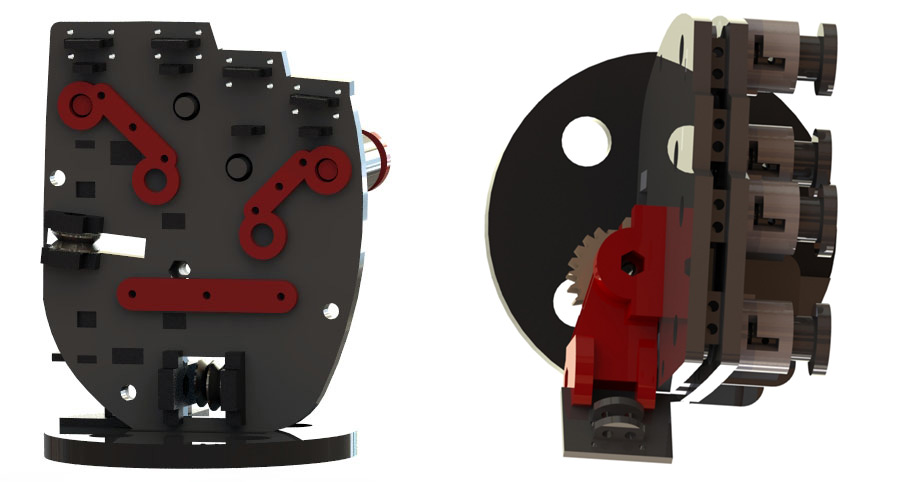

Selectively Lockable Differential Mechanism – We developed a selectively lockable differential mechanism that can block the motion of each finger independently. Such a mechanism allows the user to intuitively select the desired finger combinations. The top two bars of the whiffletree (see Fig. 2) have appropriately designed holes, and the palm accommodates a series of buttons that are elongated upon pressing. The idea is that, when each button is pressed, the elongated part fills the appropriate finger hole and the motion of this particular finger is constrained. A total of 16 different index, middle, ring and pinky combinations can be implemented using the differential mechanism and a single motor. These can be combined with the 9 discrete positions of the thumb, to produce a total of 144 different grasping postures or gestures with a single motor.

Fig. 2: The left figure presents the inner side of the palm. The three bars of the modified whiffletree are depicted with red color. The holes of the upper two bars are filled by the elongated parts of the corresponding buttons, constraining the motion of different fingers. In this instance the motion of the index and pinky fingers is constrained, resulting to a change at the inclination of the differential mechanism finger bars. The right figure depicts the thumb mechanism in red and golden colors.

Personalized Designs – Τhe use of parametric models derived from human hand anthropometry studies allows for the development of personalized prostheses (see Fig. 3). The only parameters required to derive the finger phalanges lengths and the personalized finger base frames positions and orientations are the human hand length (HL) and the human hand breadth (HB).

The proposed hands can be fabricated using off-the-shelf, low-cost materials and rapid prototyping techniques (3D printing) or standard machinery tools (CNC, laser cutters etc). All required materials can be easily found in hardware stores around the world.

You can use the following link to order your personalized design (.CAD files): Web Form for Personalized Designs. All cad files (Solidworks .sldasm, .sldprt and .dwg, .dxf, .stl), required for the replication of the proposed design are distributed through our website.

Fig. 3: Personalized designs. Two different robot hand models are depicted. The left hand version was created with a total length of 17.8cm, while the right hand version with a total length of 19cm.

Fig. 4. The prosthetic hand developed by the OpenBionics team.

The proposed design is fully described in the following paper:

George P. Kontoudis, Minas V. Liarokapis, Agisilaos G. Zisimatos, Christoforos I. Mavrogiannis and Kostas J. Kyriakopoulos, “Open-Source, Anthropomorphic, Underactuated Robot Hands with a Selectively Lockable Differential Mechanism: Towards Affordable Prostheses”, IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg (Germany), 2015 (under review).

The OpenBionics initiative provides also designs for open-source, affordable (<100$), light-weight (<200gr), under-actuated robot hands.

Experiments conducted with the proposed hands can be found at the following videos:

More information can be found in our website, http://www.openbionics.org, Facebook, Twitter:

References:

[1] D. Edeer and C. W. Martin, “Upper limb prostheses – a review of the literature with a focus on myoelectric hands,” 2013. [Online]. Available: www.worksafebc.com/evidence

[2] L. Birglen and C. M. Gosselin, “Force analysis of connected differential mechanisms: application to grasping,” The International Journal of Robotics Research, vol. 25, no. 10, pp. 1033–1046, 2006.

[3] M. V. Liarokapis, P. K. Artemiadis, and K. J. Kyriakopoulos, “Quantifying anthropomorphism of robot hands,” in IEEE International Conference on Robotics and Automation (ICRA). IEEE, 2013, pp. 2041–2046.

[4] B. Buchholz, T. J. Armstrong, and S. A. Goldstein, “Anthropometric data for describing the kinematics of the human hand.” Ergonomics, vol. 35, no. 3, pp. 261–73, 1992.

Recent Publications:

Agisilaos G. Zisimatos, Minas V. Liarokapis, Christoforos I. Mavrogiannis and Kostas J. Kyriakopoulos, “Open-Source, Affordable, Modular, Light-Weight, Underactuated Robot Hands”, IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Chicago (USA), 2014. [BibTeX] [PDF]

Minas V. Liarokapis, Panagiotis K. Artemiadis and Kostas J. Kyriakopoulos, “Quantifying Anthropomorphism of Robot Hands”, IEEE International Conference on Robotics and Automation

(ICRA), Karlsruhe (Germany), 2013. [BibTeX] [PDF]

Agisilaos G. Zisimatos, Minas V. Liarokapis, Christoforos I. Mavrogiannis, George P. Kontoudis and Kostas J. Kyriakopoulos, “How to Create Affordable, Modular, Light-Weight, Underactuated, Compliant Robot Hands”, Control Systems Lab, School of Mechanical Engineering, National Technical University of Athens, January 2015. [BibTeX] [PDF]

****

Editor’s note:

The OpenBionics initiative is not to be confused with Open Bionics Ltd (ex featured here).

If you liked this article, you may also be interested in:

- DARPA’s HAPTIX project hopes to provide prosthetic hands with sense of touch

- Lifehand 2 prosthetic grips and senses like a real hand

- Revolutionary implant enables broken spinal cord to function again

- Introducing the Cybathlon

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: 3D printing, c-Health-Medicine, cx-Research-Innovation, open source, Service Professional Medical Prosthetics