Robohub.org

Robots can help reduce 35% of work days lost to injury

Robot in assembly. Source: bmwgroup

What’s the biggest benefit for using collaborative robots? It’s not better efficiency. It’s not the extra hours the robot can work in a shift. It’s not even having improved consistency across your product. Whilst these are all great bonuses the biggest benefit of robots is their impact on reducing workplace injury.

Workplace injury is an issue that affects millions of workers worldwide, each year. It costs businesses billions in revenue. Although it’s not possible to avoid all injuries completely, many workplace injuries are avoidable. Musculoskeletal disorders are often preventable, as they are usually caused by bad workplace ergonomics. Collaborative robots are a great way to solve this problem.

In a previous article, we found how collaborative robots are designed to be ergonomic products in themselves. In this article, we’ll look at how collaborative robots can be used to reduce ergonomic problems across your workplace. We’ll also show how you can pick the best tasks for your collaborative robot by putting on your “ergonomics glasses.”

Musculoskeletal Disorders: Too important to ignore

Musculoskeletal disorders (or MSDs) refer to a set of injuries and disorders that affect the human body’s movement or musculoskeletal system, for example, the muscles, joints, tendons, nerves and ligaments. According to FitForWork Europe, MSDs are a huge problem in the modern world. 21.3% of disabilities worldwide are due to MSDs, and they are estimated to cost the European Union around 240 billion euros each year in lost productivity and absence, due to sickness. MSDs accounted for 35% of all work days lost in 2007 in Austria.

As they are caused by repetitive physical stresses on the human body some industries are more affected by it than others. Manufacturing and food processing are classed as high-risk, as outlined this report on the impact of MSDs in the USA. Some jobs are prone to specific injuries due to the type of work involved, such as industrial inspection and packaging jobs, which are prone to upper extremity MSDs. In 2012, the manufacturing industry had the fourth highest number of MSDs, with 37.4 incidents per 10,000 workers.

All this injury costs your business money; a lot of money. Ergo-Plus shows you would have to generate $8 million worth of extra sales to cover the cost associated with the most common MSDs. This is crazy, as the injuries are preventable by simply applying basic ergonomic principles.

How robots can reduce workplace injury

In 2013, we reported on a case study at Volkswagen, who had applied the UR5 collaborative robot to their facility. In it, Jürgen Häfner explained their reasons for introducing the robot:

“We would like to prevent long term burdens on our employees in all areas of our company with an ergonomic workplace layout. By using robots without guards, they can work hand in hand together with the robots. In this way, the robot becomes a production assistant in manufacture and as such can release staff from ergonomically unfavorable work.”

Source: Robotiq

You can improve a task’s ergonomics in two ways:

- Use ergonomic principles to redesign the task, to reduce the physical stress on the worker.

- Find a way to complete the stressful part of the task differently, without using a human worker at all. This can hugely reduce the chance of MSDs.

The use of collaborative robots falls squarely into the second category. However, you still need to have a knowledge of ergonomic principles to know if a task can cause MSDs.

How to tell if a task can cause MSDs

Ergonomic professionals sometimes talk about having “ergonomics glasses” to mean viewing the workplace from an ergonomics perspective. Before you learned about ergonomics, you could have easily failed to notice that a task could injure a worker. After learning about them, ergonomics issues will jump out at you as you walk through your workplace. There are two different types of ergonomics:

- Proactive Ergonomics – This involves solving ergonomics issues before they arise, either by walking around your workplace whilst “wearing your ergonomics glasses” or by incorporating ergonomic principles into the initial design of processes.

- Reactive Ergonomics – This is what usually happens. It’s solving a problem when it is already a problem. A worker suffers an injury as a result of the task and so we retrospectively try to improve the ergonomics of the task.

At the very least, we should adopt a more proactive approach to ergonomics. In an ideal world, all ergonomics issues would be solved proactively, before they arise. However, being realistic, we’re likely to end up with a combination of the two approaches.

Three steps to improve ergonomics with collaborative robots

Applying ergonomics principles is really quite simple. It just involves a slight change of mindset and three easy steps.

Step 1: Learn what to look out for

The first step to proactive ergonomics is to learn how to spot bad ergonomics. There are some great resources online, particularly the free resources and blogs from Ergo-Plus, the International Labor Organization, Dan MacLeod and FitForWork Europe.

There are a few fundamental principles of ergonomics, which can vary slightly in wording depending on which resource you consult. Tasks which violate one or more of these will need to be redesigned or passed off to a robot, to avoid inflicting injury on the worker over time:

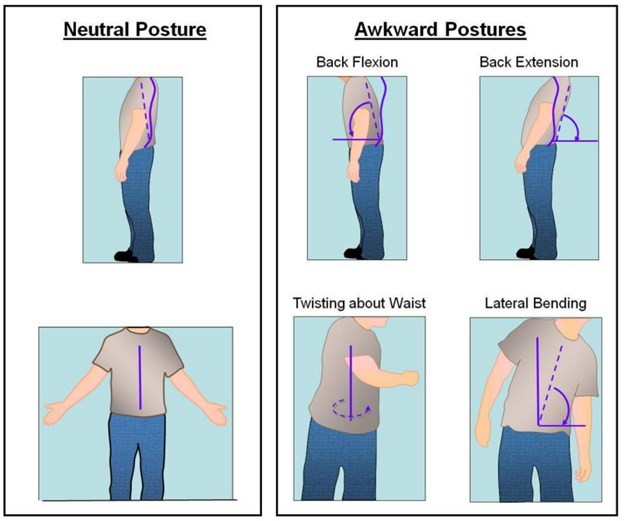

- Workers must maintain a neutral posture without putting their body in awkward positions.

- Reduce excessive forces and vibrations on the human body.

- Keep everything in easy reach and at the proper height, to allow the worker to operate in the natural power/comfort zones of the human body.

- Reduce excessive motions in the task. This is especially important in repeated motions.

- Minimize fatigue, static load and pressure points on the human body.

- Provide adequate clearance and lighting in the workplace.

- Allow the worker to move, exercise and stretch. After all, the human body is “designed to move” not stay in the same position for long periods of time.

Neutral and awkward back postures (source)

Become familiar with these principles by reading over the linked resources and looking at example images of good and bad ergonomic practices.

Step 2: Stand up and walk!

The second step is to stand up off your chair and walk around your workplace, noticing everything you can about the ergonomics of the tasks. Ask yourself (and then ask your colleagues) the following two questions:

- How could this task be improved to make it more comfortable (less physically stressful) to the worker?

- Which parts of the task could we give to a collaborative robot to solve the ergonomic issues?

We recommend that you take photos and videos of the tasks, to document the ergonomics improvement process. This will be useful in two ways, as you can then use the same photos to help you to design your collaborative robot process.

Step 3: Apply collaborative robots to improve ergonomics

Once you have identified problem areas in the workplace, you are likely to have a list of tasks which need improvement. Some of the tasks will be possible to carry out with a collaborative robot. Others will not, so you will need to improve their ergonomics in other ways.

Best practices for looking at tasks ergonomically

With so much information available about ergonomics, you might be thinking that you’d have to invest big in training to become a proactive ergonomics business. However, this is not necessarily the case. You can start small and still see big benefits. The International Labor Organization gives three simple things to remember when applying ergonomics to your workplace:

- It is most effective to examine tasks on a case-by-case basis. Ergonomics issues can be very specific to a task, so don’t think that doing exactly the same everywhere in the workplace will be effective. Start small, looking at just one or two tasks, and build up gradually.

- Even minor changes to ergonomics can drastically reduce injury. It might seem trivial to have a robot pick up a part and move it 50cm to be closer to a human operator, but after an 8 hour shift this simple movement can mount up to a huge physical strain on the worker. Simply knowing that the optimal working radius of a table is 25cm allows you to understand this and put it into practice.

- Staff should be involved in making any ergonomics changes to the workplace. People themselves are the best source of insight into how to improve their work tasks. Get your workers involved right from the start to identify problem areas and apply collaborative robots.

tags: c-Health-Medicine, collaborative robots