Robohub.org

Small UAV turbojet engine developed in Japan

Source: DigInfo TV/YouTube

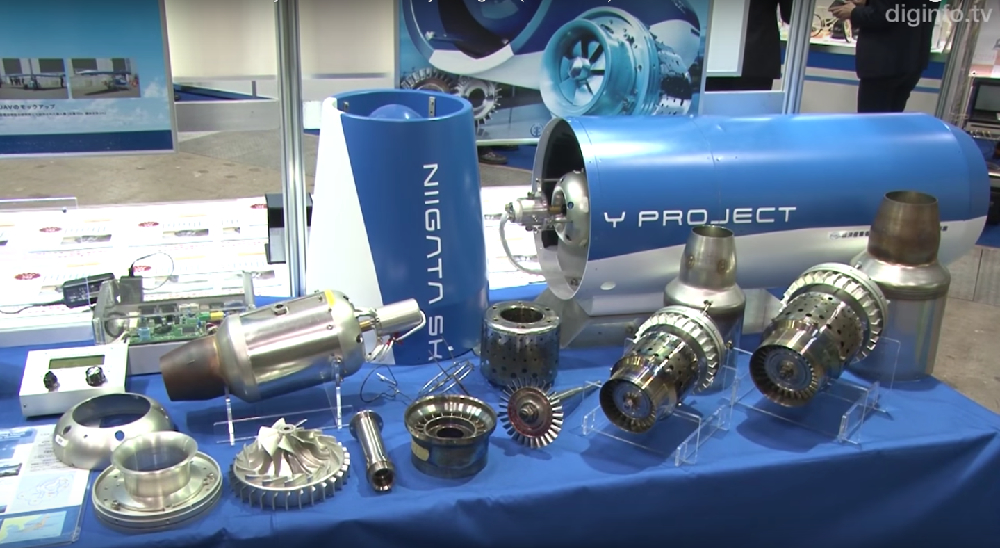

YSEC, with support from the government, and in partnership with national research institution AIST and small- to medium-sized companies in Niigata Prefecture with superior technology in metal processing and control systems, and based on its own proprietary cutting technology, has developed a small jet engine for use in unmanned aerial vehicles.

A UAV with two of these engines would weigh about 100 kg, and be able to carry about 100 kg of cargo, depending on fuel load.

“To date, we have achieved our goal of 100,000 rpm, and met the target specification for a maximum thrust of 18 kg force. The part at the intake port is called the impeller, which doesn’t get hot so we used magnesium alloy there. This is an extremely light and strong alloy. The turbine, at the jet exhaust side, gets extremely hot. For that part, we used Inconel alloy, an ultra heat resistant alloy, the same as is used on engines for ordinary passenger jets. We used hang glider sails for the wing.”

A UAV with two of these engines can fly 100 km at a height of 200 meters. For takeoff and landing the plane needs a straight path of about 25 meters, so a typical school ground would provide sufficient space. YSEC is targeting usage in UAVs to carry supplies to isolated islands or disaster areas.

Source: DigInfo TV/YouTube

“Rather than building and selling airplanes, we think the most practical business scenario is for us to develop a vehicle to meet a user’s specific needs, and then sell or lease a full system, including us providing pilot services. We have also received inquiries from schools that want to use our technology for student research; we think we can probably sell a few, maybe ten or more, per year.”

If you liked this article, you may also be interested in:

- How might drone racing drive innovation?

- FAA issues waivers for real estate and agricultural UAVs

- Small UAV coalition applauds the FAA’s release of the proposed suas rule as a good first step for industry

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: c-Aerial