Robohub.org

Next-generation robotic cockroach can explore under water environments

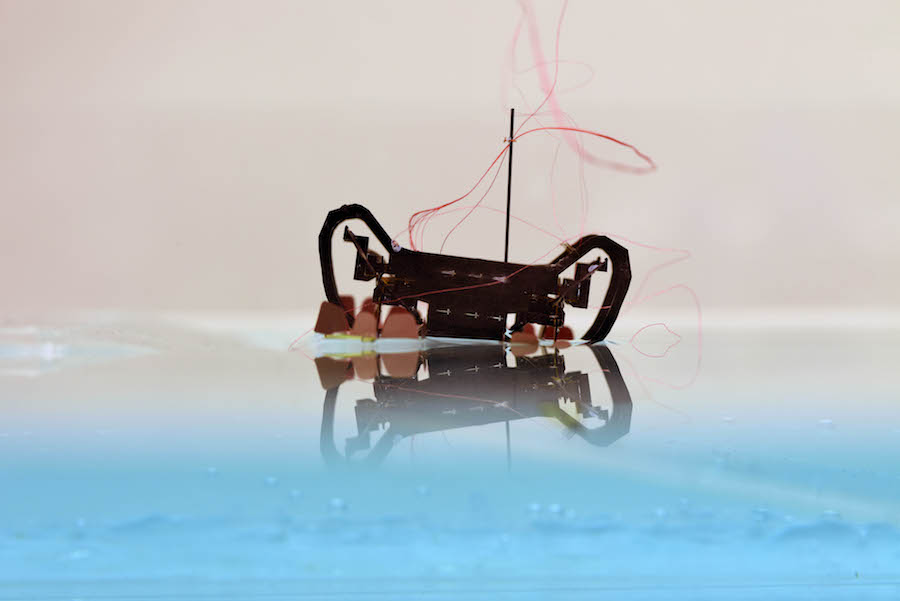

When HAMR needs to sink, its footpads emit a high voltage to break the water surface tension. This process is called electrowetting, which is the reduction of the contact angle between a material and the water surface under an applied voltage. This change of contact angle makes it easier for objects to break the water surface. (Credit: Yufeng Chen, Neel Doshi, and Benjamin Goldberg/Harvard University)

By Leah Burrows

In nature, cockroaches can survive underwater for up to 30 minutes. Now, a robotic cockroach can do even better. Harvard’s Ambulatory Microrobot, known as HAMR, can walk on land, swim on the surface of water, and walk underwater for as long as necessary, opening up new environments for this little bot to explore.

This next generation HAMR uses multifunctional foot pads that rely on surface tension and surface tension-induced buoyancy when HAMR needs to swim but can also apply a voltage to break the water surface when HAMR needs to sink. This process is called electrowetting, which is the reduction of the contact angle between a material and the water surface under an applied voltage. This change of contact angle makes it easier for objects to break the water surface.

Moving on the surface of water allows a microrobot to evade submerged obstacles and reduces drag. Using four pairs of asymmetric flaps and custom designed swimming gaits, HAMR robo-paddles on the water surface to swim. Inspired by the gait of a diving beetle, the researchers exploited the unsteady interaction between the robot’s passive flaps and the surrounding water to effectively swim forward and turn.

“This research demonstrates that microrobotics can leverage small-scale physics — in this case surface tension — to perform functions and capabilities that are challenging for larger robots,” said Kevin Chen, Ph.D., a postdoctoral fellow at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) and first author of the paper.

The most recent research is published in the journal Nature Communications.

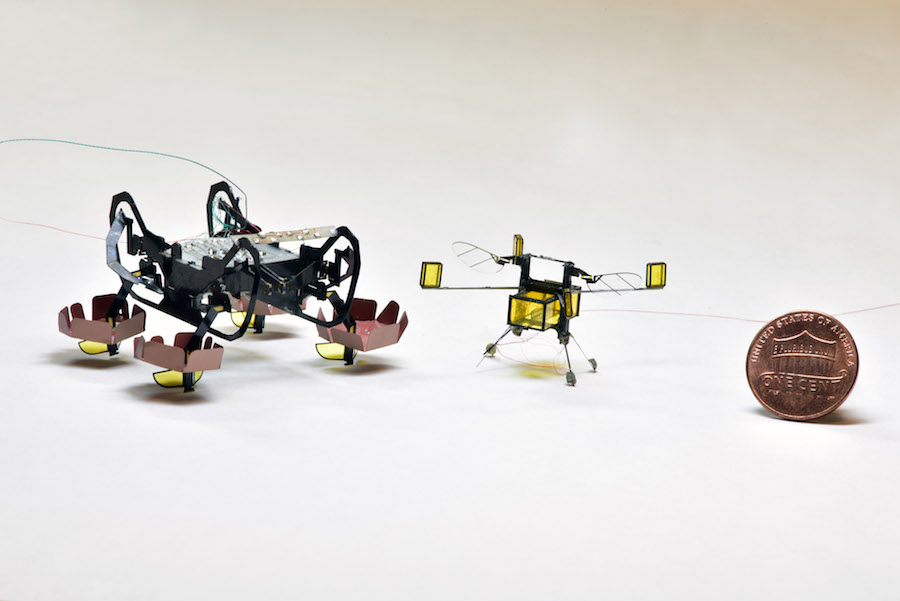

“HAMR’s size is key to its performance,” said Neel Doshi, graduate student at SEAS and co-author of the paper. “If it were much bigger, it would be challenging to be support the robot with surface tension and if it were much smaller, the robot would need a lot more force to break it.”

HAMR weighs 1.65 grams (about as much as a large paper clip), can carry 1.44 grams of additional payload without sinking and can paddle its legs with a frequency up to 10 Hz. It’s coated in Parylene to keep it from shorting under water.

Once below the surface of the water, HAMR uses the same gait to walk as it does on dry land and is just as mobile. Getting out of the water, however, is an enormous challenge. The water’s surface tension force is twice HAMR’s weight and the induced torque causes a dramatic increase of friction on the robot’s hind legs. The researchers stiffened the robot’s transmission and installed soft pads to the robot’s front legs to increase payload capacity and redistribute friction during climbing. Finally, walking up a modest incline, the robot is able break out of the water’s hold.

Havard’s Ambulatory Microrobot (HAMR) joins the Robobee (right) as a microrobot that can transition between air and water (Credit: Yufeng Chen, Neel Doshi, and Benjamin Goldberg/Harvard University)

“This robot nicely illustrates some of the challenges and opportunities with small-scale robots,” said senior author Robert Wood, Ph.D., Core Faculty member at the Wyss Institute for Biologically Inspired Engineering and the Charles River Professor of Engineering and Applied Sciences at Harvard’s Paulson School of Engineering and Applied Sciences. “Shrinking brings opportunities for increased mobility – such as walking on the surface of water – but also challenges since the forces that we take for granted at larger scales can start to dominate at the size of an insect.”

Next, the researchers hope to further improve HAMR’s locomotion and find a way to return to land without a ramp, perhaps incorporating gecko-inspired adhesives or impulsive jumping mechanisms.

This research was co-authored by Benjamin Goldberg and Hongqiang Wang, Ph.D.. It was supported by the Wyss Institute for Biologically Inspired Engineering, the Harvard John A. Paulson School of Engineering and Applied Science, and the Office of Naval Research’s Defense University Research Instrumentation Program.

- WYSS TECHNOLOGY – Versatile Ambulatory Microrobots

- PUBLICATION – Nature Communications: Controllable water surface to underwater transition through electrowetting in a hybrid terrestrial-aquatic microrobot