Robohub.org

Creating a synthetic “second skin” with soft pneumatic actuators

Photos courtesy: RRL, EPFL and NCCR Robotics

Soft pneumatic actuators (SPAs) are an up and coming solution to the contradictory design criteria that many robotic systems have – high torque/force often means greater weight and volume, which is impractical and often specifically against the purpose of wearable robots. Taking the principles of pneumatic artificial muscles (PAMs) which have been used for powering orthoses since the 1960s, SPAs are a soft solution for creating a bending motion while not being limited to a single direction of movement, and as such can be used for a wider range of applications.

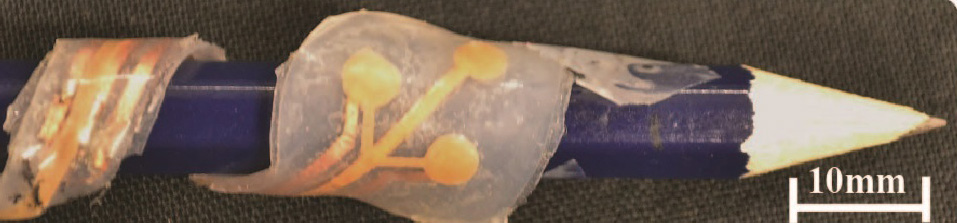

Orthoses (exoekeletons) used for training to regain movement in patients after stroke suffer from a number of common problems; they are uncomfortable and bulky and thus have not yet been integrated into common usage. To make a truly practical device that is useable on a day-to-day basis, tactile interfaces on the surface need to be lightweight, compliant, safe and have multiple points of sensing and actuation. A team from RRL, EPFL and NCCR Robotics presents a Soft Pneumatic Actuator (SPA)-skin embedded with piezo electric (PZT) sensors to tackle these problems and provide vibrotactile feedback.

SPA-based skin allows bidirectional tactile information transfer to facilitate simpler and responsive wearable interface. By creating an interface made from SPAs and designed to be worn over the skin, it is possible to create a synthetic “second skin” that is thin, lightweight and flexible, meaning that sensors can be placed across all points of the hand (like nerves across your skin) but when the wearer bends their hand, the skin and the integrated tactile feedback system both follow it.

Photos courtesy: RRL, EPFL and NCCR Robotics

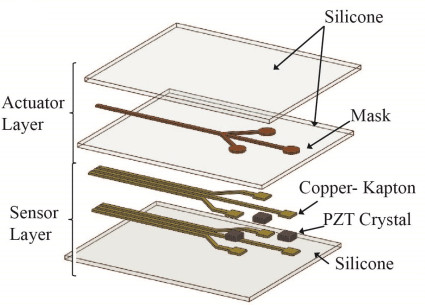

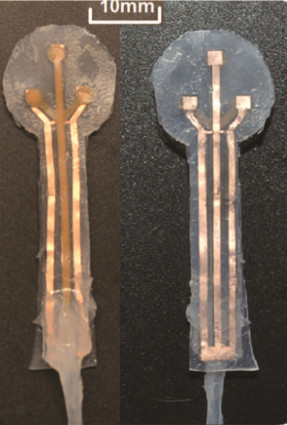

SPA-skin is made of two layers, a lower sensor layer and an upper actuator layer. The actuator layer is made of two silicone sheets with a mask between them to prevent the layers sticking. The final design is 1.4 mm-thick including the integrated sensor layer. To create actuation (or movement) air is pumped into a 3-4mm diameter bubble between the layers, which creates forces of up to 0.3N, which may sound small, but is comparable to pressures experienced by the human hand on a daily basis. The sensor layer is created using piezoelectric ceramic elements embedded into silicone sheets which convert mechanical stress (the pressure exerted by touching something) into an electrical voltage. This voltage is then used to measure the strength of vibrations that come from both the actuator and the external interaction forces faced by SPA skin.

Photos courtesy: RRL, EPFL and NCCR Robotics

The presented SPA-skin produces vibrotactile feedback (a vibration is initiated to facilitate haptic feedback) over a range of frequencies. Sensors embedded inside can detect vibrations from actuators at the same time as external interaction forces applied by something touching the skin. This measured sensor information is then used to actively control vibration strength from the actuators. In other words, the “skin” can detect that it is touching something, and also, modulate the vibration accordingly so that the sense of feeling (the haptic sensation) is consistent.

SPA-skin provides a highly customisable and a wearable physical interface with facility of the closed-loop control for multiple vibrotactile signals. It may find uses anywhere that requires a wearable device for vibrotactile feedback across the human body. As described above, it can be used as a plug and play component for a feedback mechanism in rehabilitation devices for training patients with loss of movement e.g. after stroke, or for providing a sense of touch in virtual reality games.

Reference

H.A. Sonar and J. Paik, “Soft Pneumatic Actuator Skin with Piezoelectric Sensors for Vibrotactile Feedback“, Frontiers in Robotics and AI, doi:10.3389/frobt.2015.00038

tags: c-Research-Innovation, NCCR Robotics