Robohub.org

DNA-inspired ‘supercoiling’ fibres could make powerful artificial muscles for robots

Shutterstock

The double helix of DNA is one of the most iconic symbols in science. By imitating the structure of this complex genetic molecule we have found a way to make artificial muscle fibres far more powerful than those found in nature, with potential applications in many kinds of miniature machinery such as prosthetic hands and dextrous robotic devices.

The power of the helix

DNA is not the only helix in nature. Flip through any biology textbook and you’ll see helices everywhere from the alpha-helix shapes of individual proteins to the “coiled coil” helices of fibrous protein assemblies like keratin in hair.

Some bacteria, such as spirochetes, adopt helical shapes. Even the cell walls of plants can contain helically arranged cellulose fibres.

Muscle tissue too is composed of helically wrapped proteins that form thin filaments. And there are many other examples, which poses the question of whether the helix endows a particular evolutionary advantage.

Many of these naturally occurring helical structures are involved in making things move, like the opening of seed pods and the twisting of trunks, tongues and tentacles. These systems share a common structure: helically oriented fibres embedded in a squishy matrix which allows complex mechanical actions like bending, twisting, lengthening and shortening, or coiling.

This versatility in achieving complex shapeshifting may hint at the reason for the prevalence of helices in nature.

Fibres in a twist

Ten years ago my work on artificial muscles brought me to think a lot about helices. My colleagues and I discovered a simple way to make powerful rotating artificial muscle fibres by simply twisting synthetic yarns.

These yarn fibres could rotate by untwisting when we expanded the volume of the yarn by heating it, making it absorb small molecules, or by charging it like a battery. Shrinking the fibre caused the fibres to re-twist.

Read more:

Show us your (carbon nanotube artificial) muscles!

We demonstrated that these fibres could spin a rotor at speeds of up to 11,500 revolutions per minute. While the fibres were small, we showed they could produce about as much torque per kilogram as large electric motors.

The key was to make sure the helically arranged filaments in the yarn were quite stiff. To accommodate an overall volume increase in the yarn, the individual filaments must either stretch in length or untwist. When the filaments are too stiff to stretch, the result is untwisting of the yarn.

Learning from DNA

More recently, I realised DNA molecules behave like our untwisting yarns. Biologists studying single DNA molecules showed that double-stranded DNA unwinds when treated with small molecules that insert themselves inside the double helix structure.

The backbone of DNA is a stiff chain of molecules called sugar phosphates, so when the small inserted molecules push the two strands of DNA apart the double helix unwinds. Experiments also showed that, if the ends of the DNA are tethered to stop them rotating, the untwisting leads to “supercoiling”: the DNA molecule forms a loop that wraps around itself.

Read more:

Fishing for artificial muscles nets a very simple solution

In fact, special proteins induce coordinated supercoiling in our cells to pack DNA molecules into the tiny nucleus.

We also see supercoiling in everyday life, for example when a garden hose becomes tangled. Twisting any long fibre can produce supercoiling, which is known as “snarling” in textiles processing or “hockling” when cables become snagged.

Supercoiling for stronger ‘artificial muscles’

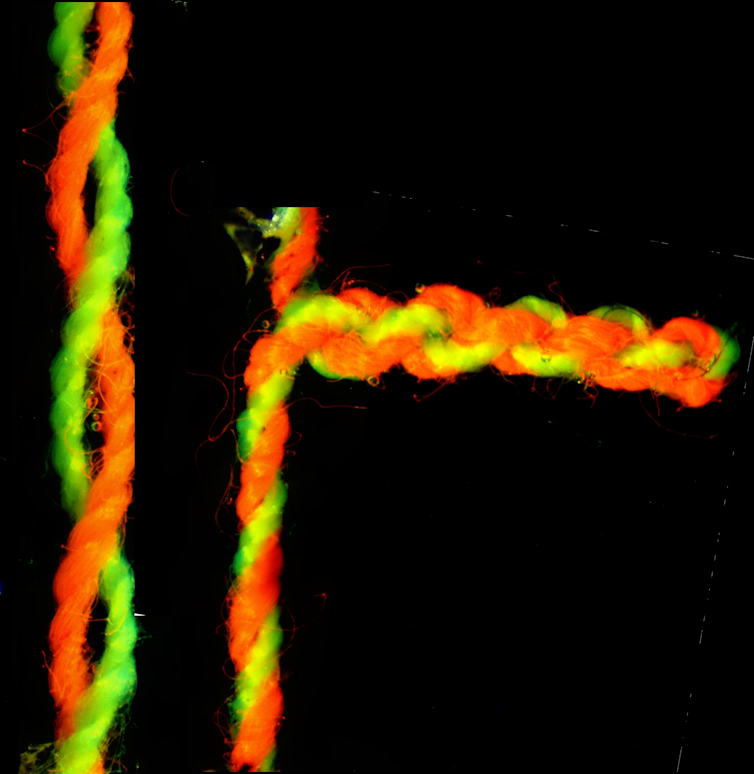

Our latest results show DNA-like supercoiling can be induced by swelling pre-twisted textile fibres. We made composite fibres with two polyester sewing threads, each coated in a hydrogel that swells up when it gets wet and then the pair twisted together.

Swelling the hydrogel by immersing it in water caused the composite fibre to untwist. But if the fibre ends were clamped to stop untwisting, the fibre began to supercoil instead.

Geoff Spinks, Author provided

As a result, the fibre shrank by up to 90% of its original length. In the process of shrinking, it did mechanical work equivalent to putting out 1 joule of energy per gram of dry fibre.

For comparison, the muscle fibres of mammals like us only shrink by about 20% of their original length and produce a work output of 0.03 joules per gram. This means that the same lifting effort can be achieved in a supercoiling fibre that is 30 times smaller in diameter compared with our own muscles.

Why artificial muscles?

Artificial muscle materials are especially useful in applications where space is limited. For example, the latest motor-driven prosthetic hands are impressive, but they do not currently match the dexterity of a human hand. More actuators are needed to replicate the full range of motion, grip types and strength of a healthy human.

Electric motors become much less powerful as their size is reduced, which makes them less useful in prosthetics and other miniature machines. However, artificial muscles maintain a high work and power output at small scales.

To demonstrate their potential applications, we used our supercoiling muscle fibres to open and close miniature tweezers. Such tools may be part of the next generation of non-invasive surgery or robotic surgical systems.

Many new types of artificial muscles have been introduced by researchers over the past decade. This is a very active area of research driven by the need for miniaturised mechanical devices. While great progress has been made, we still do not have an artificial muscle that completely matches the performance of natural muscle: large contractions, high speed, efficiency, long operating life, silent operation and safe for use in contact with humans.

The new supercoiling muscles take us one step closer to this goal by introducing a new mechanism for generating very large contractions. Currently our fibres operate slowly, but we see avenues for greatly increasing the speed of response and this will be the focus for ongoing research.

Geoff Spinks does not work for, consult, own shares in or receive funding from any company or organisation that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

Original post published in The Conversation.

tags: c-Research-Innovation