Robohub.org

Factory-in-a-Day: EU FP7 invests €7.9M to make robotics affordable for SMEs

Factory-in-a-Day is an EU initiative to develop a robotic system that is inexpensive, leasable, and can be set up and working in 24 hours. The goal is to make advanced robotic systems, which currently take weeks or months to deploy, more attainable for small and medium sized enterprises (SMEs). SME’s have not tended to invest in robotics technology because human workers are more efficient at adapting to the small production batches typical of most SMEs, and state-of-the-art systems are not flexible enough to adapt to changing processes, making large financial investments in these systems infeasible even when the processes are easily automated. Factory-in-a-Day aims to develop a system that can be easily re-purposed for new product lines — by reducing the system integration time to a single day, the project hopes to minimize investment risk for SMEs. The EU’s FP7 Program has invested €7.9M in this €11M project.

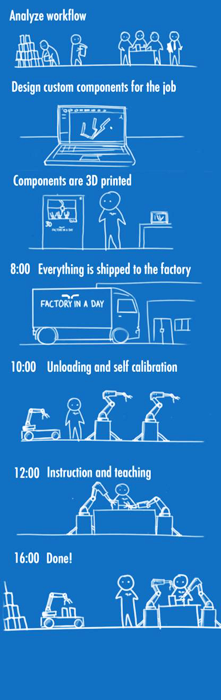

To make a one-day deployment feasible, project leaders envision that some of the work will need to be done ahead of time. Before the robot is even taken to the SME premises, the process would be analyzed to determine which tasks are best done by the robot and which are best left to humans; for greatest efficiency, the robots would do the repetitive work, and the humans would perform the hard-to-automate tasks that require flexibility and problem solving. After the workflow has been designed, customer-specific hardware components would be 3D-printed and installed on the standardized robot grippers. Only then would the robot and any auxiliary components (like cameras) be brought to the production facility.

The hope is that actual deployment would unfold quickly thereafter: once on site, the robot would be connected to the machinery software through a brand-independent software system, and then taught how to perform its set of tasks (such as grasping an object) by a human co-worker. A set of predefined skills — similar to Apps for smart phones — would help speed the process.

Here’s a run-down of the challenges:

- Safety: Safe robot arms with inherent mechanical safety, novel proximity-sensing skin, and dynamic contact-avoiding behaviours will be needed to allow robots to operate safely alongside human co-workers.

- Platform independence: Platform-independent harmonized robot software will be needed to allow seamless integration with existing machinery.

- Automatic calibration: Auto-calibration of all robots and auxiliary systems, without altering the environment, will be needed for quick onsite deployment.

- Standardization: Standard core hardware modules (e.g. adaptive grippers and arms) and additive manufacturing (3D printing) procedures will need to be brought together for high-speed hardware development and installation.

- Fast deployment: Fast teaching software for on-site robot “programming” will be needed so that only essential parameters and trajectories need to be taught by humans.

Coordinated by the University of Delft, the project will involve 16 partners from academia and industry including Siemens, Fraunhofer, Universal Robots, Philips and the Technische Universität München (TUM). The consortium aims to have the workflow process designed within the first year, to have the software prototype tested for the first use case by the third year, and to have evaluated and tested all use-cases by the end of the four-year project.

tags: c-Research-Innovation, cx-Industrial-Automation, FP7, Industrial Automation