Robohub.org

I am FRANKA: German collaborative robot can build itself

Source: Franka.de

The robotic industry is currently surfing on a new wave of collaborative robots. With several big companies trying to make their way into the market, there is still a huge effort from emergent companies to get a piece of the market. This new German collaborative robot is continuing this wave of small companies emerging with some awesome concepts.

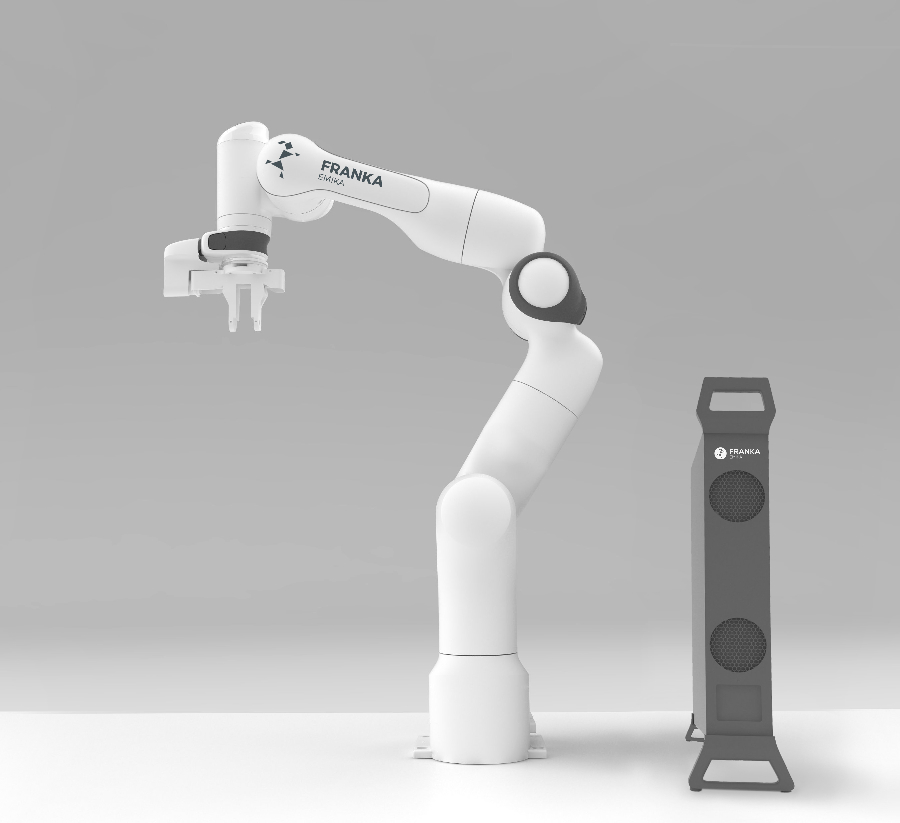

Here’s Franka.

With one of the most fast growing robotic economy in the world and a huge emphasis on safety, this is not a surprise to see a German company launching a new cobot. In fact, Germans are still refusing to use some of the collaborative robots on the market because of safety concerns. With the new ISO/TS 15066 out, I guess it was time for a German company to launch a robot that seems to operate within the guidelines of the technical specification.

What’s under the HOOD?

We don’t have a lot of details on the use of this robot, but we do have information on its specifications.

Source: franka.de

The 7-axis Franka has a 3kg payload and a 800mm reach. The robot has a +/-0.1mm repeatability and has force torque sensors in every single joint. It has a 60mm stroke parallel gripper with limited force (140N) that fits perfectly with the new ISO/TS 15066. The gripper also has 3D printed interchangeable fingers. The user interface is a web browser that seems to be really intuitive for programming. With some icons here and there, you can teach a couple of waypoints and there you go, your robot is running. The robot’s weight is only 18.5kg, which makes it easy to place pretty much anywhere you can think of.

At 9,900 Euros (+/- 12,000 USD), this robot is totally shocking the robotic industry. In fact, with many functionalities and a very low price, it can certainly mix things up during a customer’s search for an easy to use and cheap solution.

This robot makes me think of the Gomtec Roberta (bought by ABB in 2015). The same mentality seems to drive the design of this robot. A simple and easy to use robot with embedded sensors and a gripper of high quality, which makes human robot interaction very safe.

Automatica

It is very refreshing to see this type of a robot out there. It’s been a while (since IREX actually) that anyone has announced a new collaborative robot. With the upcoming Automatica, I am sure that some companies will be showcasing new robots and hopefully we will see many of the previous robots, which were still prototypes getting out on the market.

I am also looking forward to see robots that will have ISO/TS 15066 oriented specification or modifications. This will be an interesting summer for collaborative robots.

tags: c-Industrial-Automation, robotiq