Robohub.org

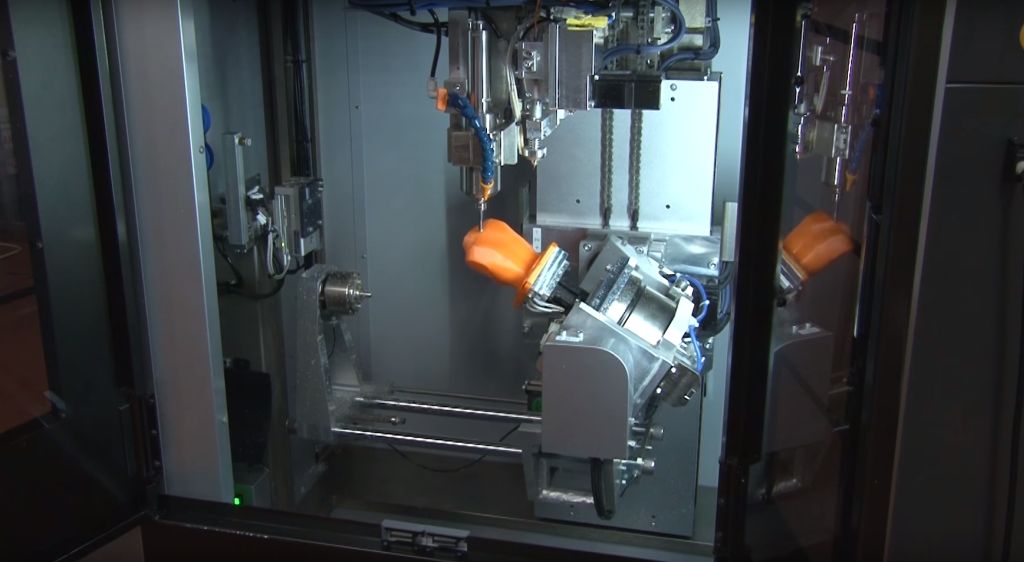

Japan’s first 5-axis hybrid 3D printer

Source: DigInfo TV/Youtube

In a collaborative research effort, Enomoto Kogyo, Shizuoka University of Art and Culture, and software company C&G Systems have developed Japan’s first 5-axis hybrid 3D printer, capable of continuously performing lamination and cutting using 5-axis control technology.

“Conventional (3D) printers are primarily planar lamination printers, but this machine is capable of not only planar lamination, but also 5-axis lamination,” said Kawamura Takehire, Enomoto development department chief director. “Ordinarily, undercutting can’t be performed with 3-axis control type NC, but with 5 axis, tilt and rotation functions are added. In other words, control is implemented for the X, Y, Z, tilt and rotation axis, and as a result, we’re able to print very complex shapes.”

“Our (3D) printer was produced as a machine for use in R&D by professionals rather than everyday users. We want to cultivate a wide-range of various applications and would like to hear from customers about what types of applications they would like to jointly develop, or in other words, what types of items they would like to print with this machine.”

Conventional 3D printers typically need the use of a support material to prevent material from drooping when a sphere is modeled. However, since this printer is capable of performing lamination on 5 axis, the use of a support material is not required, so material costs are reduced. It is well-suited for prototyping prosthetic leg parts, other products in the medical care field, and aircraft parts, since it combines lamination and machining in the manufacturing process.

If you liked this article, you may also be interested in:

- Autonomous mobile additive manufacturing robot runs circles around traditional 3D printers

- Hacking your 3D printer to make an air hockey robot

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: c-Industrial-Automation