Robohub.org

Mix-and-match kit could enable astronauts to build a menagerie of lunar exploration bots

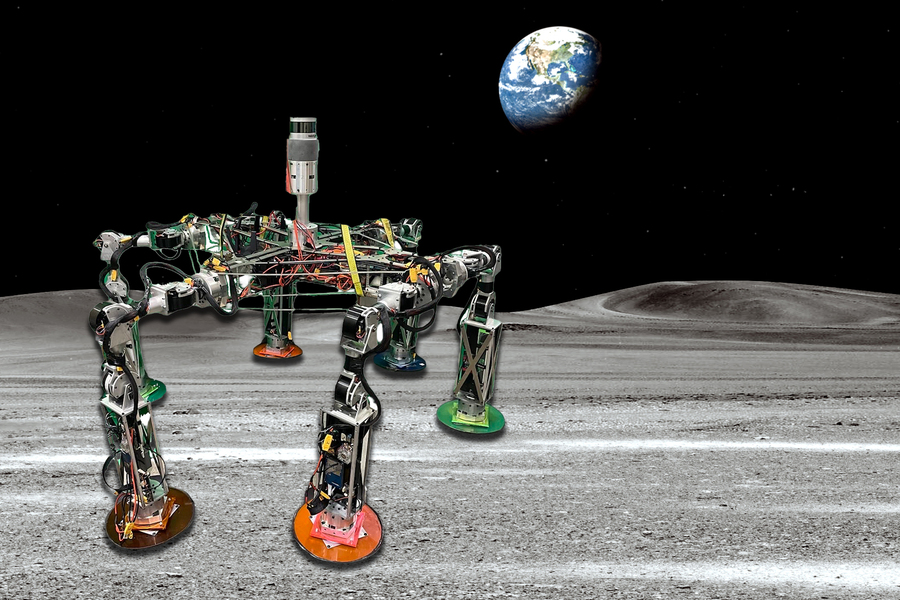

A team of MIT engineers is designing a kit of universal robotic parts that an astronaut could easily mix and match to build different robot “species” to fit various missions on the moon. Credit: hexapod image courtesy of the researchers, edited by MIT News

By Jennifer Chu | MIT News Office

When astronauts begin to build a permanent base on the moon, as NASA plans to do in the coming years, they’ll need help. Robots could potentially do the heavy lifting by laying cables, deploying solar panels, erecting communications towers, and building habitats. But if each robot is designed for a specific action or task, a moon base could become overrun by a zoo of machines, each with its own unique parts and protocols.

To avoid a bottleneck of bots, a team of MIT engineers is designing a kit of universal robotic parts that an astronaut could easily mix and match to rapidly configure different robot “species” to fit various missions on the moon. Once a mission is completed, a robot can be disassembled and its parts used to configure a new robot to meet a different task.

The team calls the system WORMS, for the Walking Oligomeric Robotic Mobility System. The system’s parts include worm-inspired robotic limbs that an astronaut can easily snap onto a base, and that work together as a walking robot. Depending on the mission, parts can be configured to build, for instance, large “pack” bots capable of carrying heavy solar panels up a hill. The same parts could be reconfigured into six-legged spider bots that can be lowered into a lava tube to drill for frozen water.

“You could imagine a shed on the moon with shelves of worms,” says team leader George Lordos, a PhD candidate and graduate instructor in MIT’s Department of Aeronautics and Astronautics (AeroAstro), in reference to the independent, articulated robots that carry their own motors, sensors, computer, and battery. “Astronauts could go into the shed, pick the worms they need, along with the right shoes, body, sensors and tools, and they could snap everything together, then disassemble it to make a new one. The design is flexible, sustainable, and cost-effective.”

Lordos’ team has built and demonstrated a six-legged WORMS robot. Last week, they presented their results at IEEE’s Aerospace Conference, where they also received the conference’s Best Paper Award.

MIT team members include Michael J. Brown, Kir Latyshev, Aileen Liao, Sharmi Shah, Cesar Meza, Brooke Bensche, Cynthia Cao, Yang Chen, Alex S. Miller, Aditya Mehrotra, Jacob Rodriguez, Anna Mokkapati, Tomas Cantu, Katherina Sapozhnikov, Jessica Rutledge, David Trumper, Sangbae Kim, Olivier de Weck, Jeffrey Hoffman, along with Aleks Siemenn, Cormac O’Neill, Diego Rivero, Fiona Lin, Hanfei Cui, Isabella Golemme, John Zhang, Jolie Bercow, Prajwal Mahesh, Stephanie Howe, and Zeyad Al Awwad, as well as Chiara Rissola of Carnegie Mellon University and Wendell Chun of the University of Denver.

Animal instincts

WORMS was conceived in 2022 as an answer to NASA’s Breakthrough, Innovative and Game-changing (BIG) Idea Challenge — an annual competition for university students to design, develop, and demonstrate a game-changing idea. In 2022, NASA challenged students to develop robotic systems that can move across extreme terrain, without the use of wheels.

A team from MIT’s Space Resources Workshop took up the challenge, aiming specifically for a lunar robot design that could navigate the extreme terrain of the moon’s South Pole — a landscape that is marked by thick, fluffy dust; steep, rocky slopes; and deep lava tubes. The environment also hosts “permanently shadowed” regions that could contain frozen water, which, if accessible, would be essential for sustaining astronauts.

As they mulled over ways to navigate the moon’s polar terrain, the students took inspiration from animals. In their initial brainstorming, they noted certain animals could conceptually be suited to certain missions: A spider could drop down and explore a lava tube, a line of elephants could carry heavy equipment while supporting each other down a steep slope, and a goat, tethered to an ox, could help lead the larger animal up the side of a hill as it transports an array of solar panels.

“As we were thinking of these animal inspirations, we realized that one of the simplest animals, the worm, makes similar movements as an arm, or a leg, or a backbone, or a tail,” says deputy team leader and AeroAstro graduate student Michael Brown. “And then the lightbulb went off: We could build all these animal-inspired robots using worm-like appendages.’”

The research team in Killian Court at MIT. Credit: Courtesy of the researchers

Snap on, snap off

Lordos, who is of Greek descent, helped coin WORMS, and chose the letter “O” to stand for “oligomeric,” which in Greek signifies “a few parts.”

“Our idea was that, with just a few parts, combined in different ways, you could mix and match and get all these different robots,” says AeroAstro undergraduate Brooke Bensche.

The system’s main parts include the appendage, or worm, which can be attached to a body, or chassis, via a “universal interface block” that snaps the two parts together through a twist-and-lock mechanism. The parts can be disconnected with a small tool that releases the block’s spring-loaded pins.

Appendages and bodies can also snap into accessories such as a “shoe,” which the team engineered in the shape of a wok, and a LiDAR system that can map the surroundings to help a robot navigate.

“In future iterations we hope to add more snap-on sensors and tools, such as winches, balance sensors, and drills,” says AeroAstro undergraduate Jacob Rodriguez.

The team developed software that can be tailored to coordinate multiple appendages. As a proof of concept, the team built a six-legged robot about the size of a go-cart. In the lab, they showed that once assembled, the robot’s independent limbs worked to walk over level ground. The team also showed that they could quickly assemble and disassemble the robot in the field, on a desert site in California.

In its first generation, each WORMS appendage measures about 1 meter long and weighs about 20 pounds. In the moon’s gravity, which is about one-sixth that of Earth’s, each limb would weigh about 3 pounds, which an astronaut could easily handle to build or disassemble a robot in the field. The team has planned out the specs for a larger generation with longer and slightly heavier appendages. These bigger parts could be snapped together to build “pack” bots, capable of transporting heavy payloads.

“There are many buzz words that are used to describe effective systems for future space exploration: modular, reconfigurable, adaptable, flexible, cross-cutting, et cetera,” says Kevin Kempton, an engineer at NASA’s Langley Research Center, who served as a judge for the 2022 BIG Idea Challenge. “The MIT WORMS concept incorporates all these qualities and more.”

This research was supported, in part, by NASA, MIT, the Massachusetts Space Grant, the National Science Foundation, and the Fannie and John Hertz Foundation.