Robohub.org

New additive manufacturing method builds up objects with real 3D curves instead of 2D layers

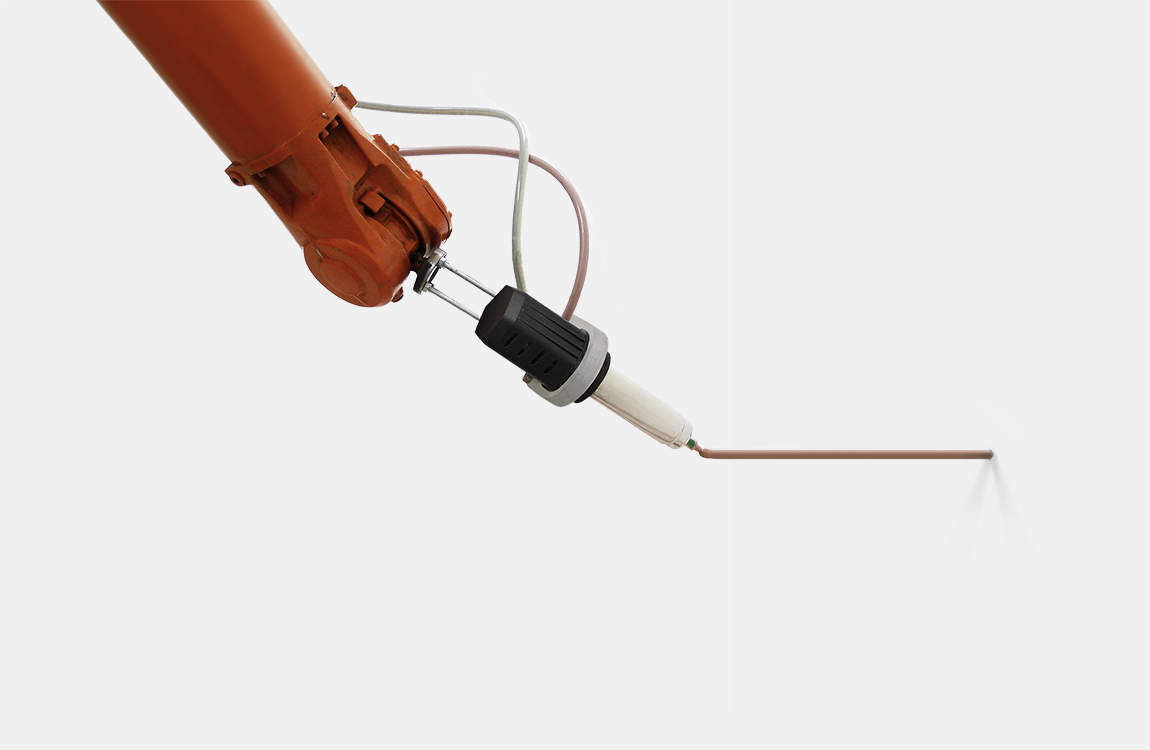

Mataerial is a new 3D printing method that uses extrusion technology and a two-component thermosetting polymer to build up objects on any working surface that the polymer can adhere to, including floors, walls and ceilings, without the need for additional support structures. While other 3D printing methods build up objects by successive 2D layering, this process truly builds up objects in all three dimensions: a script takes 3D models designed by the user in CAD software, converts them into 3D curves and then these 3D curves are converted into paths that are fed to the robotic arm. By combining these 3D curves, a variety of shapes can be achieved that would be impossible with other 3D printing methods.

Mataerial is a new 3D printing method that uses extrusion technology and a two-component thermosetting polymer to build up objects on any working surface that the polymer can adhere to, including floors, walls and ceilings, without the need for additional support structures. While other 3D printing methods build up objects by successive 2D layering, this process truly builds up objects in all three dimensions: a script takes 3D models designed by the user in CAD software, converts them into 3D curves and then these 3D curves are converted into paths that are fed to the robotic arm. By combining these 3D curves, a variety of shapes can be achieved that would be impossible with other 3D printing methods.

Mataerial is a research collaboration between Petr Novikov and Sasa Jokic from the Institute for Advanced Architecture of Catalonia (IAAC) and Joris Laarman Studio. The team spent months developing and testing to arrive at a working prototype, which was released just this past weekend. According the Novikov, there are no immediate plans to produce and sell Mataerial, but this may happen in the near future.

Check out their demo:

tags: 3D printing, c-Research-Innovation