Robohub.org

PLA vs. ABS: What’s the difference?

PLA food industry prototypes

PLA and ABS are the 2 most common FDM desktop printing materials. Both are thermoplastics, meaning they enter a soft and moldable state when heated and then return to a solid when cooled. Via the FDM process, both are melted and then extruded through a nozzle to build up the layers that create a final part. This article will discuss the main differences between these two commonly used materials.

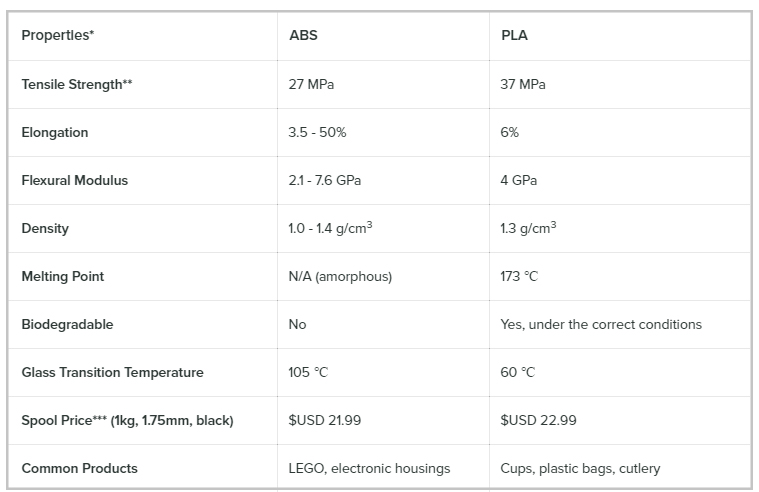

The table below compares the main properties of ABS vs. PLA:

*Sourced from MakeItFrom

**Sourced from Optimatter for a test specimen with 100% infill, 0.2mm layer height printed in a linear pattern

*** Sourced from Amazon ABS & PLA

What are ABS and PLA?

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic well known in the injection molding industry. It is used for applications such as LEGO, electronic housings and automotive bumper parts.

PLA (Polylactic Acid) is a biodegradable (under the correct conditions) thermoplastic derived from renewable resources such as corn starch or sugarcane. It is one of the most popular bioplastics, used for many applications ranging from plastic cups to medical implants.

Part accuracy

Generally the tolerances and accuracy of FDM printed components are largely dependent upon printer calibration and model complexity. However, ABS and PLA can be used to create dimensionally accurate parts, printing details down to 0.8mm and minimum features down to 1.2mm. For connecting or interlocking parts, a tolerance of 0.5mm is recommended and using a minimum wall thickness of 1 – 2 mm will ensure adequate strength in wall elements.

Due to its lower printing temperature, PLA, when properly cooled, is less likely to warp (making it easier to print with) and can print sharper corners and features compared to ABS.

Strength

With similar tensile strengths, ABS and PLA are both adequate for many prototyping applications. ABS is often preferred due to its improved ductility over PLA. With a higher flexural strength and better elongation before breaking, 3D printed ABS can be employed for end use applications whereas PLA remains popular for rapid prototyping when form is more critical than function.

Surface finish and post processing

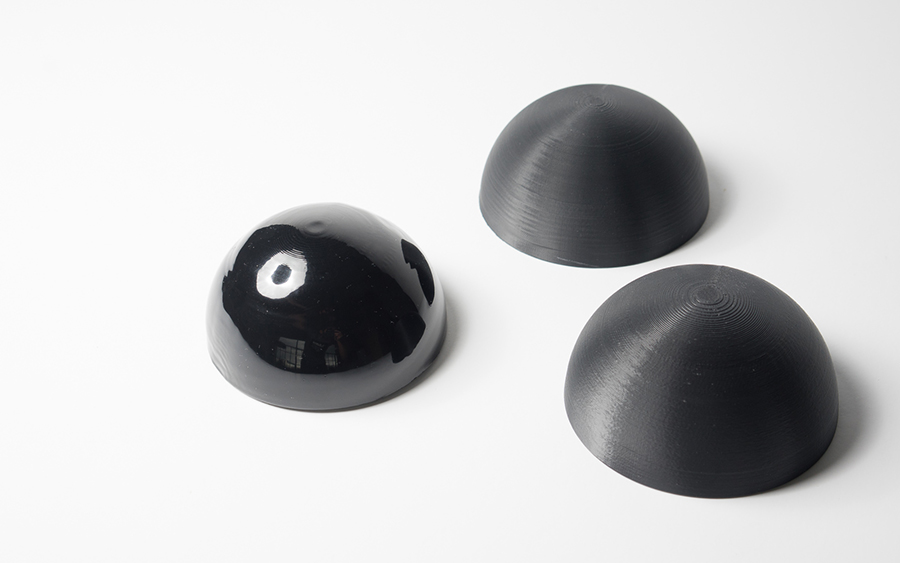

The nature of printing with FDM means that for both ABS and PLA, the print layers will be visible after printing. ABS typically prints in a matte finish while PLA is semi-transparent, often resulting in a glossier finish.

Acetone is often used in post processing to smooth ABS, also giving the part a glossy finish. ABS is regularly machined after printing and can easily be sanded. PLA can also be sanded and machined, however greater care is required.

If the aesthetics of a part are critical, then printing using SLA or Polyjet is recommended.

A 100 micron ABS print with Acetone treatment (Left), a 100 micron ABS print (middle) and a 200 micron ABS print (right)

Heat resistance

For high temperature applications, ABS (glass transition temperature of 105°C) is more suitable than PLA (glass transition temperature of 60 °C). PLA can rapidly lose its structural integrity and can begin to droop and deform, particularly if under load, as it approaches 60 °C.

Biodegradability

PLA is stable in general atmospheric conditions and will biodegrade within 50 days in industrial composters and 48 months in water. ABS is not biodegradable, however it is recyclable. PLA is regularly used for the production of food related items, however confirmation by the filament manufacturer that it is safe to do so is recommended.

Rules of thumb

- ABS and PLA are the most common desktop FDM printed materials and are typically similar in cost. ABS has superior mechanical properties but is harder to print with compared to PLA.

- ABS is best suited for applications where strength, ductility, machinability and thermal stability are required. ABS is more prone to warping.

- PLA is ideal for 3D prints where aesthetics are important. Due to its lower printing temperature is easier to print with and therefore better suited for parts with fine details.

Check out 3D Hubs Knowledge Base to read more articles for engineers and designers to learn about 3D printing.

tags: 3D printing, c-Education-DIY, education