Robohub.org

Removing steps of common processes

Professor Robert J. Flatt. Source: DFAB

Being able to control the moment when concrete turns from liquid to solid is crucial for digitally fabricated concrete structures. The timing of this process can be controlled by tuning the chemistry and adding small amounts of specific substances at just the right time. Robert J. Flatt, Professor of Building Materials at ETH Zurich, discusses this process and the innovations in concrete chemistry and digital fabrication he and his team are working on to reduce the environmental footprint of the most used building material in the world.

“Test the limits and break through (…) no rules for me (…) let it go!”, you used this song from the Disney film “Frozen” in a presentation on your research. How are you working to get rid of rules?

I’d rather say: We try to do things that, at first, seem unfeasible. Lets take the making of a cake as an analogy. In general you have dough, which is fluid. You pour it into a mould and then put it into the oven to harden. What we are working on is similar to a process that would extrude this dough and have it immediately shaped and cooked. You could say: We are trying to remove steps of common processes by forcing the material to behave differently.

“The key is to use the critical moment when the material transforms from liquid to solid.” What does this mean in practice?

We are working on what I call the “spices” of concrete. Added to a mixture in very small amounts, these additives have a huge impact on the material properties. I give you an example. The research project “Smart Dynamic Casting” (SDC), a collaboration with the ETH Chair of Architecture and Digital Fabrication, started with the question: Can you make complex shapes of concrete without any formwork? SDC is an answer to this challenge, in which the key is to be able to use the critical moment when the material transforms from liquid to solid; when you can shape the material, but it doesn’t collapse under its own weight.

SDC also has been your first collaboration in the field of digital fabrication, before joining the National Centre of Competence in Research (NCCR) Digital Fabrication. Where are the synergies between material sciences and digital fabrication?

Digital fabrication in concrete wouldn’t work without the manipulation of the material properties. You either would end up with a very inefficient process or the process would simply fail. On the other hand, robotic control opens new perspectives to surpass current state-of-the-art construction processes, particularly for more individualized structures. For me this interdependency of material design and robotic processes is the exciting part about this research field, and bringing our expertise to this collaboration is where we see our role within the NCCR Digital Fabrication.

“A big opportunity is to combine the manipulation of the material properties with the reduction of the environmental footprint.” What is the added value of these new fabrication processes and materials compared to traditional ways of building?

If you take SDC, the overall interest was to be more efficient in producing complex shapes. So the added value is about creativity and efficiency. Furthermore, by replacing traditional formwork with a single adjustable slip-form, waste can be reduced. However, in terms of the overall environmental impact I consider the elimination of the formwork to be of second order. A much bigger opportunity is to combine the manipulation of the material properties with the reduction of the environmental footprint of concrete. Accordingly, the development of more environmentally friendly types of concrete is one of our main research focuses and also one of our major long-term goals, of which we plan to feed the results into the NCCR Digital Fabrication.

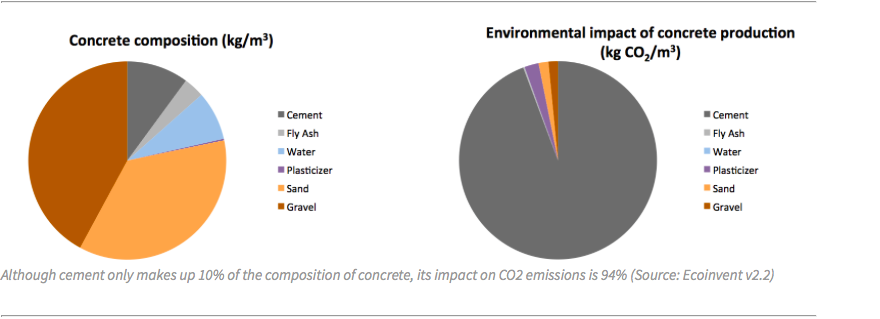

5 to 8% of the man made CO2 emissions is effected by cement production. Why do you focus on concrete and not on a building material with less environmental impact?

Concrete is the most used building material in the world. It is used in larger quantities than all the other building materials added together [1]. There are basically no other materials available in the quantity that can compete with concrete in terms of performance, environmental impact and cost. This huge volume of concrete also means that: If you simply succeed in reducing the amount of cement used in concrete you have a huge multiplication factor. As an example: about 40% of Switzerland’s Kyoto Protocol objectives where reached by the cement industry. Part of this reduction is due to the fact, that less concrete was used, part of it due to improvements in production, and part due to changes in the nature of the cement being produced. That brings us back to the “spices”; these additives can be used to tune the material properties, but you also can use them to keep required values of some properties while changing the proportions of the materials you used. As an example; chocolate producers are now allowed to replace 5% of the cacao fat with vegetable oil, but of course they don’t want to change the taste. In our research we try to do the same, but our goal is not to replace 5%, but 50% of the material. To accomplish this we need to formulate very good spices for it to go unnoticed!

In your experience, what factors are required for a research innovation so that industry will take interest?

An innovation, of course, needs a market perspective. In this sense environmental aspects are certainly a macro trend that impacts their long-term strategic considerations, however it is clearly the costs of materials, energy, and the impact of CO2 emissions that will influence marketability in the long term. The balances between impact issues and how to bring an innovation to market are definitively the high-level strategic considerations for industry.

So, if the NCCR Digital Fabrication wants to be successful, in practice it should focus on environmental issues?

This conclusion is too limited and brief, whereas the goals of the NCCR Digital Fabrication are long-term. I would rather describe the process as such: In the first phase we are more in the logic of developing something like a Formula One car, a niche product. So, of course we are concerned with doing things in a sustainable way, but we are still addressing a small portion of the market. We are looking at opportunities with high added value, rather than large volumes where processes are much more optimized and margins are very tight. At this stage looking at the large volume market from the perspective of digital fabrication could be a killer for innovation. Then, in a later stage, we intend to evaluate which part of our innovations can be adapted to larger scale use. This is where we can optimally shift our attentions to larger issues such as sustainability. Once we have resolved the smaller scale problems we can shift to volumes that allow us to have a large-scale ambition and a large-scale impact to improve sustainability.

Are there any risks you can think of regarding the path on which this NCCR is heading?

If you want to build a Formula One car and you can build it more efficiently with a robot that has special features, you might well be persuaded to also use this very versatile robot for normal serial production, but this may not be the most optimal solution. The big question for me is: Will our increased use of digital fabrication eventually lead to automation with a loss of design individualization? This is, of course, exactly the opposite of what we are aiming to accomplish within the NCCR Digital Fabrication. So, to answer your question, I think it is our mandate to bring affordable “mass customization” into construction and to use our research to ensure that individualization of design and construction is available for everyone.

[1] Yearly volumes: concrete 10 km3, fired clay 2 km3, timber 1.3 km3, steel 0.1 km3.

On this subject see also the newspaper contribution “Gewürze für mehr Nachhaltigkeit” of 25.06.2015 in “Tages-Anzeiger” (in German only).

tags: c-Research-Innovation, cx-Industrial-Automation, ETH Zurich