Robohub.org

Rising need for nursery, indoor and vertical farming

To meet rising food demands from a growing global population, over 250 million acres of arable land will be needed – about 20% more land than all of Brazil. Alternatively, agricultural production will need to be more productive and more sustainable using our present acreage. Meeting future needs requires investment in alternative practices such as urban and vertical farming as well as existing indoor and covered methods.

Ray Kurzweil, futurist, inventor and Google’s Director of Engineering, said in an interview in The Times in 2013:

There will be a new vertical agriculture revolution, because right now we use up a third of the usable land of the world to produce food, which is very inefficient. Instead we will grow food in a computerized vertical factory building (which is a more efficient use of real estate) controlled by artificial intelligence, which recycles all of the nutrients so there’s no environmental impact at all.

Fully automated regional vertical farms for leafy greens and other commodity crops has long been a vision of the future. Capital costs and other vagaries have prevented such development to date, but lower costs for technology and automation plus higher costs for labor, land and other resources, are making Kurzweil’s predictions come true. There are dozens of vertical farms around the world today with more being built.

Spread, a Japanese factory farmer with a large facility near Kyoto that serves the two metropolitan areas of Kyoto and Osaka, is nearing completion of a fully automated 52,000 sq ft facility where 98% of water will be recycled and seeding, watering, applying fertilizer and harvesting will all be automated. No earth; just shelves on top of shelves from floor to ceiling. They predict 30,000 heads of lettuce can be harvested and delivered daily throughout the year.

Spread, a Japanese factory farmer with a large facility near Kyoto that serves the two metropolitan areas of Kyoto and Osaka, is nearing completion of a fully automated 52,000 sq ft facility where 98% of water will be recycled and seeding, watering, applying fertilizer and harvesting will all be automated. No earth; just shelves on top of shelves from floor to ceiling. They predict 30,000 heads of lettuce can be harvested and delivered daily throughout the year.

Propelling this indoor and vertical farming movement are three influential trends. The Boston Consulting Group, in 2015, produced a study entitled “Crop Farming 2030, the Reinvention of the Sector,” and cited (1) the steady global movement toward precision farming, (2) the availability of economical automation and robotics, and (3) the growing labor shortage as the drivers of the movement.

Vertical farming:

Food grown year round in buildings near urban centers provides many advantages: being close to the point of consumption reduces both distribution costs and spoilage. Outdoor farming is vulnerable to pests and disease, which in turn means intensive use of pesticides and herbicides causing problems with runoff as well as food safety. Vertical farms protect crops from weather and pests and reduce or eliminate the use of pesticides and herbicides. Hydroponic and aeroponic water methods save massive amounts of water compared to outdoor farming. Consequently, as these farms become more prevalent, they could provide a major new role for the ag industry to produce a wide range of commercial crops with major savings in space and water use. In the case of Spread, cited above, they are able to grow lettuce indoors using less than 1% of the water that California Central Valley growers use to grow the same product!

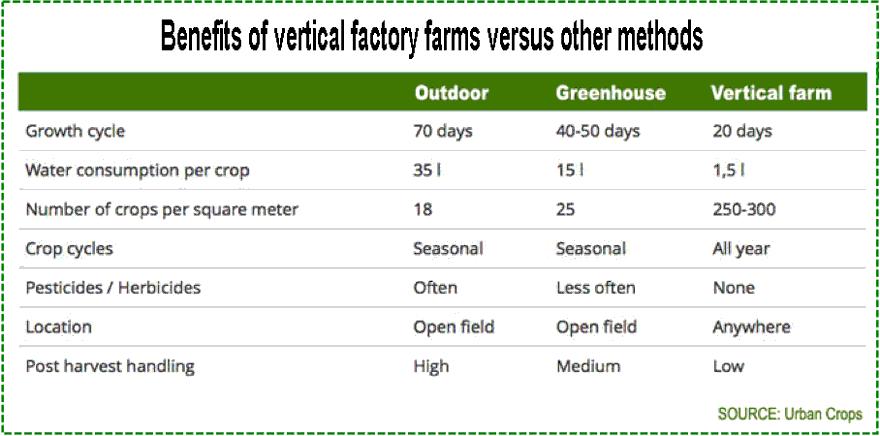

Agriculture accounts for around 70% of water used in the world today according to the OECD (Organization for Economic Co-operation and Development). As population and climate change progress, food needs will grow, and more efficient use of water in ag must happen as well. Vertical farms reduce water usage through recirculating hydroponics, evaporative cooling, control of in- and out-airflow, and other methods. Urban Crops, a Belgian factory farmer and technology provider uses this chart to show the benefits of vertical factory farms versus other methods:

Greenhouse and wholesale nurseries

Greenhouse technology is ideal to protect plants from adverse climatic conditions, insects and disease and to nurse, propagate and grow plants to usable and/or harvestable size. Greenhouses can be framed or inflated structures covered with glass or transparent or translucent material. Greenhouse yields are often 10-15% greater that outdoor yields, consistency and quality tend to be greater, and the growing season is longer.

Similar to vertical farms, greenhouses have high upfront costs and operating expenses, and crop selection must not require pollination. Whether plants are grown in the field or indoors, nurseries transplant, graft, or germinate plants to create seedlings for resale. Their processes are quite complex on two levels: (1) the technical aspects of growing plants which require management of the environment, plant nutrition, propagation, transplanting, irrigation, and pest and disease control, and (2) the business aspects of managing production, labor, customers, distribution and other activities associated with a business. Many nurseries use automation and some level of robotics. Harvest Automation and their mobile robots rearranging potted plants and Urbinati and Visser and their robotic transplanting devices are all examples of the levels of automation utilized in nursery operations.

Commercial and emerging providers:

- AeroFarms – A NJ indoor farmer that is marketing their technology to other prospective vertical farmers. AeroFarms grows a wide variety of leafy greens without sun or soil in a fully-controlled indoor environment using a system of aeroponic misting of the roots for faster harvest cycles, predictable results, food safety and less environmental impact.

- Aris – is a Dutch engineering and systems provider. Many of their projects are integrated with vision and robotics that identify, grade, sort and analyze everything from orchids to chickens, from potted plants to seedlings. Using their systems, nursery clients can then grade and robotically cut branches which can then be potted.

- ALCI Visionics & Robotics – A French integrator of vision and robotics technologies for meat and fish slicing and packaging and for nurseries and growers for potting plants and seed germination, analysis and classification for corn, rice and wheat.

- Conic Systems – a Spanish provider of greenhouse equipment including robotic and software-controlled grafting, seeding and planting systems.

- Demtec – A long established Belgium-based maker of a wide range of horticultural machinery including potting machines, seeders, planters and transplanters. Many of these processes have integrated industrial and mobile robots into their systems. Demtec robotics also play a big part in flat and shelf handling, packaging, palletization, and shipping.

- Egatec A/S – a Danish integrator of end-of-line packaging, boxing and palletizing systems for the ag and food processing industries.

- Harvest Automation – a Boston-area mobile robotics provider with nursery applications for spacing, a task that involves bending over, picking up one or two containers often weighing up to 22 pounds each, walking a few steps and then bending over again to place them in a predefined pattern. The company recently divested a warehousing variation on their mobile robot to better focus on ag industry applications.

- Helper Robotech – a Korean manufacturer of robotic grafting, smart seeding and other smart devices. They also make a wide range of nursery products to nurture seedlings to maturity.

- HETO Agrotechnics – a Dutch manufacturer of horticulture machines including robotic potting systems and pick and place systems for potted plants.

- Hortiplan – a Belgian integrator, reseller and provider of nursery equipment, supplies and mobile gully systems – which move in an automated way from the planting side to the harvesting station. Hortiplan also designs and sells lighting, irrigation and handling systems.

- Irmato Jentjens – An established Dutch builder of systems for automating food handling and packaging. Irmato also makes the Rombomatic, a robotic cutting system for nurseries that examines, assesses, cuts, powders and inserts cuttings into pots and other mediums. Jentjens is a funding partner in a variety of sensing and manipulation projects under the EU’s Clever Robots for Crops program. These include a sweet-pepper harvesting robot, an apple harvesting robot, precision and canopy-optimized spraying robots and other AI-based ag systems.

- Iron Ox – A Silicon Valley startup presently in stealth mode but hiring with a plan to provide a fully robotic, fully controlled environment for ag in a greenhouse growing leafy greens (lettuce, basil and bok choy) using natural light but mobile bots to move plants through each stage of development to harvesting, packaging and palletizing.

- ISO Group – a Netherlands-based supplier of automation solutions for nurseries. They adapt industrial robot technology for horticulture uses such as grafting, planting, vision inspection and replanting.

- Logiqs BV – a Dutch manufacturer of internal transport and logistics systems for greenhouses for growers of cut flowers, tree nurseries, flower bulbs, potted plants and vegetables. Their new modular GreenCube vertical cultivation system uses trays sensors and vertical transporters, also with sensors, for movement between layers and movement to and from the various stages of nursery growing operations.

- CMW Horticulture – a UK integrator and reseller of a whole range of greenhouse and nursery automation products including Logiqs mobility and handling systems

- Mirai Group – A Japanese farmer that, in 2009, became a member and leader of the Japanese government public-private consortium to develop low-cost plant factories. Today Mirai provides R&D and design-build services to grow leafy plants for farmers interested in vertical farming similar to what Spread is doing. Mirai is also producing and wholesaling leafy vegetables from a large plant factory located near Chiba, Japan.

- Photon Systems Instruments – An established Czech Republic provider of ag instruments including high throughput conveyor and robotic nursery phenotyping systems.

- Priva Group – a Dutch engineering, design and systems integrator for greenhouse nurseries. Recent projects include developing a leaf-removing robot for tomato plants. The lowest leaves of tomato plants are regularly removed to promote ripening (this process is called de-leafing).

- QUBIT Phenomics – a Canadian provider of conventional and robotic plant screening systems for nurseries and growers. The company’s PlantScreen™ Field Phenotyping System allows growers an automated non-invasive measurement of photosynthesis, leaf biochemical status, water status and canopy temperature. Greenhouses are the primary marketplace but the company hopes to break into field operations as well. Many major biotech companies and universities have partnered with Qubit in the study of plant responses to various stresses.

- Spread – A Japanese lettuce grower, is constructing the world’s largest plant factory near Osaka and Kyoto. The new factory, scheduled for mid-2017, will be as robotically automated as possible. Spread’s existing facility, from which they are learning what tasks can be automated, produces 21,000 heads of lettuce per day using LED lighting, controlled air conditioning and recirculating water. Spread is planning to construct and operate 20 new factories in the next 5 years in addition to selling the technology for others to build their own plant factories.

- Urban Crops – A Belgium startup pioneering the distribution of robotized vertical farming and plant factories. The company offers two types of products, one fits into a 40’ container and can be fully automated or not, and another is custom built for larger spaces. Currently the company has made a small number of sales and has partnered with companies such as Belgocatering, a Belguim based catering company, and a UAE group of investors.

- Urbinati – an Italian manufacturer of nursery technology including automated, and in some cases robotic, seeding, pot filling, transplanting, handling and irrigation devices. They also sell backroom processing robots such as palletizers.

- Transplant Systems – a NZ integrator and reseller of nursery machinery and robots from Urbinati and others.

- Visser – a Dutch provider of horticulture automation systems and complete production lines for large and small nurseries and greenhouses including a robot seeder, transplanter and packing and palletizing robots.

Agricultural Robotics: 160+ profiles

Working together with Tractica, a Colorado research firm, my team and I compiled a list of over 200 global businesses and agencies involved in developing robotic solutions for the ag industry. From that list, I was able to interview and profile over 160 companies and 16 research labs as follows:

Working together with Tractica, a Colorado research firm, my team and I compiled a list of over 200 global businesses and agencies involved in developing robotic solutions for the ag industry. From that list, I was able to interview and profile over 160 companies and 16 research labs as follows:

- Academic and research labs (16)

- Backroom and post processing (5)

- Dairy and milking (10)

- Drones, analytics and data service providers (26)

- Farm equipment manufacturers (23)

- Harvesting, weeding and thinning robots (21)

- Hobby farming (2)

- Indoor and vertical farming (23)

- Integrator, distributor and reseller (20)

- Self-driving vehicles (15)

- UAS/UAV vendors (15)

This research report will be published in the next few weeks and will contain the whole list, the profiles, and the conclusions drawn from the research, interviews and analyses. The report will be $4,200 for a Basic License (1-5 users) or $6,300 for an Enterprise License.

Note: the link to the report is to the previous report with the same title and will be updated with new information just as soon as the new report is published.

tags: agricultural robotics, Environment-Agriculture, robohub focus on agricultural robotics