Robohub.org

Rock Print: A zero-waste 3D-printed structure made only of rock and thread

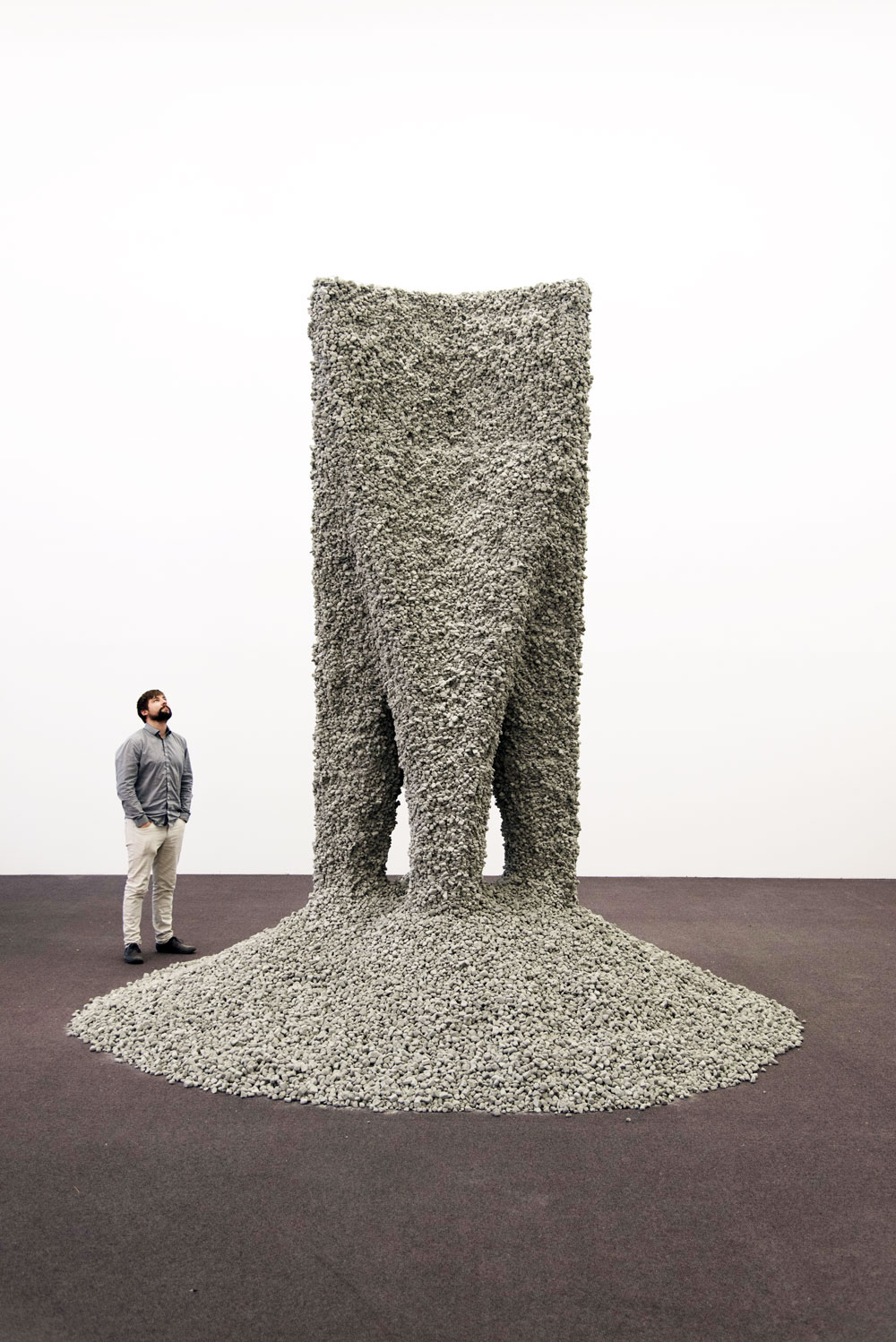

Rock Print, Architectural installation at the Chicago Architecture Biennial 2015 from Gramazio Kohler Research, ETH Zurich and the Self-Assembly Lab, MIT

Inspired to take 3D printing technology to new heights, ETH Zurich and MIT researchers create “Rock Print” — a full-scale architectural installation on display at the Chicago Architecture Biennial until January 3, 2016.

Standing over 13 feet (4 metres) high in the Chicago Cultural Center, the monolithic Rock Print installation with its rough and elegant contours confirms that collaboration inspires “State of the Art Architecture” – the theme of the inaugural Chicago Architecture Biennial.

Born out of a 2012 University of Chicago conference that brought architects, engineers, material scientists, and physicists together, Rock Print demonstrates a principle called “jamming” that refers to aggregate granular materials, like gravel that are quite literally crammed together in such a way that they hold their form and shape like a solid, even though their molecular properties are closer (in terms of behaviour) to a liquid substance.

“Jamming” together, researchers from Gramazio Kohler Research, ETH Zurich and Skylar Tibbits’ Self-Assembly Lab at the Massachusetts Institute of Technology (MIT) produced, Rock Print – a zero waste and fully reversible architectural installation for the inauguration of the Chicago Architecture Biennial that opened on 3 October 2015.

Inspired by 3D print technology

“Rock Print is a proof of concept that takes current robotic fabrication technology and applies it to a full-scale architectural project,” said Andreas Thoma, ETH Zurich.

Petrus Aejmelaeus-Lindstroem, lead researcher for the project at ETH Zurich added, “The project shows the capacity of a 3D printing process to create a geometrically-complex construction using two simple components found in everyday life – string and rocks.”

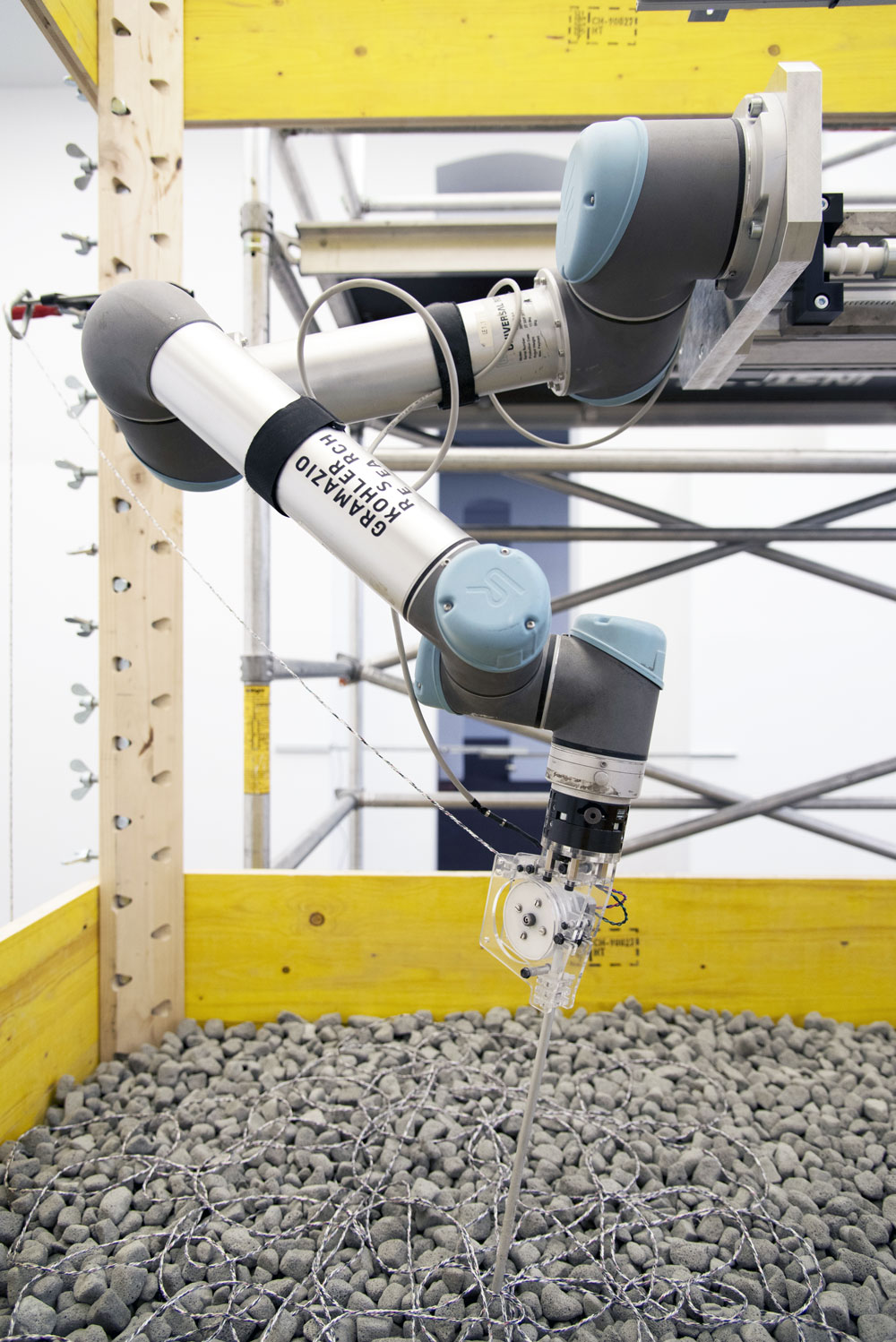

The environmentally conscious ETH and MIT installation team used a custom robotic fabrication setup to lay down nearly 5 miles (9.1 km) of a recycled textile string in a complex pattern guided by a specifically designed algorithm. Like making lasagne, the string is alternated with layers of a loose standard concrete aggregate (rocks) from the Swiss company Misapor. The company makes self-insulating concrete using crushed glass, additives, and a heating process that expands the glass into a foam-like aggregate of mostly air.

While the foam glass is a fraction of the weight of conventional gravel aggregate, Rock Print weighs in at slightly less than one tonne (970 kg to be exact). The weight is a delicate balance – a lighter weight material is necessary for an indoor installation, but the structure of the installation depends on weight to provide strength to the compressional forces that maintain its shape and to compensate for the relatively weak tensional forces.

New possibilities for the future of architecture

Matthias Kohler, who also serves as the Director of the National Competence Centre in Research (NCCR) Digital Fabrication, commented on how 3D printing technology may influence architecture in the future stating, “3D printing technology is an inspiration for the future of architecture as it brings together resource efficient additive building principles with new possibilities for design. Such technology enables production of complex forms and intricate details of building elements at a minimal cost. Today’s commercially available 3D printing technologies are not yet suitable for the scale needed for architecture or its economic and structural demands.”

The Rock Print installation challenges and expands the scope of 3D printing to an architectural scale by introducing robotic fabrication and the use of inexpensive, reconfigurable bulk construction materials. This approach attempts to open new possibilities for future architecture – using advanced digital fabrication technology to build with sustainable and locally available materials.

Kohler says, “There is still a lot of interdisciplinary research needed to fully understand and leverage future digital fabrication principles at a full building scale, but after ten intensive years of research in the field, I am positive that such new principles will not only lead to exciting architecture projects, but also to a new digital building culture – possibly to a socially relevant transformation of our built environment.”

Gramazio Kohler Research, ETH Zurich

The research group headed by Professors Fabio Gramazio and Matthias Kohler at ETH Zurich examines the changes in architectural production that result from the introduction of digital manufacturing techniques. The main focus is ground-breaking research into computational design, constructive systems and their synthesis through the use of novel robotic fabrication technologies. Lindstroem and Thoma indicated that Rock Print was made possible through the collaborative knowledge of architects, engineers, and computational physicists. Prof. Dr. Hans J. Herrmann and Dr. Falk Wittel from ETH Zurich’s Institute for Building Materials and Prof. Dr. Heinrich Jaeger from the University of Chicago consulted on the project.

Gramazio Kohler Research – Rock Print project page

Chicago Architecture Biennial 2015

Rock Print is on display throughout the biennial that runs through 3 January 2016 in the Chicago Cultural Center – the former public library across from the stunning Millennium Park in the heart of the city. Famous for its contemporary architecture and landmark skyscrapers, the Chicago Architecture Biennial celebrates with the theme, “State of the Art in Architecture” providing a platform for ground-breaking architectural projects and spatial experiments that demonstrate how creativity and innovation can radically transform our lived experience. It offers an opportunity to take stock of more than 70 architectural projects and experiments from 30 countries around the world. Rock Print represents the Swiss-US collaboration at the forefront of innovation in architecture.

If you liked this article, you may also be interested in:

- New Master of Advanced Studies (MAS) in architecture and digital fabrication at ETHZ

- Watch flying machines weave a rope bridge you can walk on

- Architectural robots: The shape of the robots that will shape your home

- Swiss to invest almost CHF30 million in digital fabrication research over next 4 years

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: 3D printing, architectural robotics, c-Research-Innovation, ETH Zurich, Gramazio & Kohler, MIT, Switzerland