Robohub.org

New electrical film that is both solid and liquid

As soft robotics increases in both scope and popularity, it is becoming more and more vital that each element of the electrical circuits contained within are also soft and elastic and able to continue to function reliably when in stressed or pressurised positions.

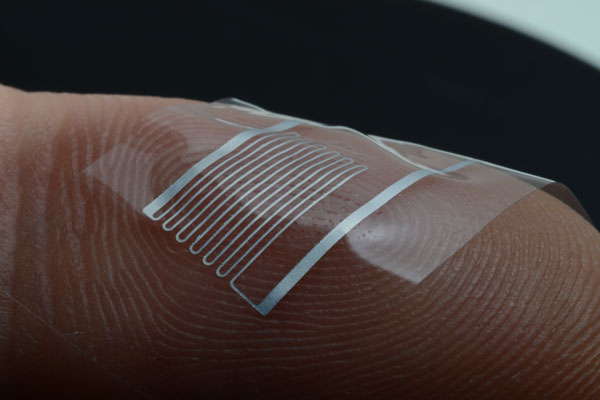

Today, a team from LSBI, EPFL and NCCR Robotics present their latest stretchable biphasic (solid-liquid) thin metal film in the journal Advanced Materials. To build the films, first a substrate (a base that the film will be built upon) of polydimethylsiloxane (PDMS) is lain. On top of this, a metallic bilayer is formed by evaporating gallium onto a 60nm thick sputtered gold film. The resulting metallic film has two distinct phases: a solid AuGa2 alloy immersed in liquid gallium that has a melting point of 29.8 oC. The thinness and deposition method of the biphasic film allow for fine and complex shape patterning using lithography techniques, similar to those obtained in metal films on rigid substrates.

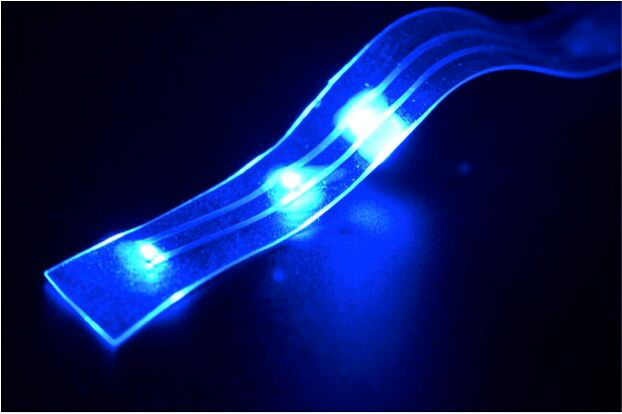

The idea of using biphasic (i.e. solid and liquid) elements within the film is that when it is bent or stretched, small cracks form within the solid alloy layer, but the liquid layer is on hand to seep into the gaps and ensure continued electrical conductivity. This elegant solution really seems to work – when tested in the lab under repeated strain and tension, the films retained low sheet resistance (< 0.5 Ω/sq), low gauge factor (sensitivity to strain) (≈ 1) and the ability to stretch by 400 % a million times without affecting function.

The resulting film is thin (<1 μm thick), lightweight and extremely versatile, with potential uses in soft robotics including medical devices where precise delivery of electrical currants are vital.

The resulting film is thin (<1 μm thick), lightweight and extremely versatile, with potential uses in soft robotics including medical devices where precise delivery of electrical currants are vital.

Reference

A. Hirsch, H.O.Michaud, A.P. Gerratt, S. de Mulatier and S.P. Lacour, “Intrinsically stretchable biphasic (solid-liquid) thin metal films,” Advanced Materials, 2016. Doi: 10.1002/adma.201506234

tags: c-Research-Innovation, NCCR Robotics, robohub focus on soft robotics