Robohub.org

RE.WORK: Meeting the challenges of commercialising robotics

Robots to install underfloor insulation in draughty homes, bots for edutainment, intelliTables and tiny robust drones flying with real bees wings – tantalising glimpses of a technology on the cusp of commercialisation.

Robots to install underfloor insulation in draughty homes, bots for edutainment, intelliTables and tiny robust drones flying with real bees wings – tantalising glimpses of a technology on the cusp of commercialisation.

RE.WORK’s Future Robotics Forum – which took place in London on Tuesday – was an opportunity to hear the stories of the developers of these and other transformative robotic services and devices, a melting pot of key influencers in this most versatile of technologies, and an opportunity to gather a great many take-home points on the challenges involved in commercialisation.

Perhaps the most important of these, it emerged, is the necessity of putting the emphasis on what you can do with the technology, rather than selling the robot itself.

This was certainly the philosophy of Matthew Holloway, managing director of Q-Bot, which supplies robots to the construction industry. While other developers looked on enviously, Holloway related how the company had achieved six figure orders in just 12 months, the majority from local authorities.

Task focussed

Holloway’s company is currently focussed on robots that can squeeze through a brick-sized vent to apply insulation under floorboards and map what they see in the process.

For Camden Council, faced with the difficulty of insulating homes that are often in conservation areas and have limited access points, this technology is particularly attractive. According to Holloway, some 20% of heat loss occurs through the floor and their bot-installed insulation can reduce drafts by 45% and save around £200 per annum per dwelling.

Holloway spoke of the importance of challenging people’s perceptions, in his company’s case proffering a solution with “intelligent devices that turn dirty jobs into clean cost effective tasks.”

This task-specific mantra was echoed by VC Ilian Iliev, CEO of the EcoMachines Incubator, who counselled developers to “focus on areas where payback is measurable.”

In his presentation, he also pointed out that hardware startups take a lot more money and time to develop than those focussing on software, so it’s important to demonstrate and validate return on investment (ROI) to clients as well as the scalability of business models across existing industrial infrastructure. He also advocated transferring “template” business models and emphasised the importance of precisely defined needs as opposed to hyping the technology.

Not just hype

Drones are one area of robotics that has been the subject of much hype recently. In fact, according to Mirko Kovac, Director of the Aerial Robotics Laboratory at London’s Imperial College, the market for drones will be worth $90bn in the coming years. Rather than focussing on money-making possibilities, Kovac pointed out the huge potential drone networks hold for parts of the world that lack a developed infrastructure, such as large parts of Africa.

But he also highlighted the challenges that need to be overcome for the technology to progress: drones still have problems with landing in a city or in forests, and there are issues with moving in complex cluttered environments, close to water and in adapting to different media.

Kovac was followed onto the podium by drone developer Glenn Smith of Maplebird. The challenges that still need to be overcome mean that the technology won’t bear fruit tomorrow, he said, but it will happen within the next 5-10 years.

And it’s largely companies such as Amazon that are doing the groundwork to prepare people for drone deliveries. Their ambition, he stressed, is a real one. Underlining how seriously the mega-corporations, such as Amazon, Google and – most recently – DHL are taking drone delivery, he joked: “You know it’s serious when the Germans get involved!”

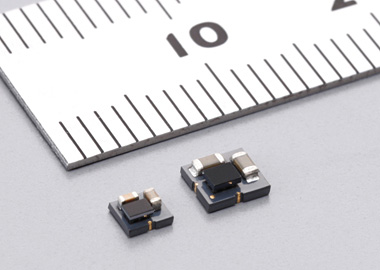

MapleBird says it has “benefited from the rapid advances in electronics driven by the smart phone industry, as both have common requirements for high processing power of data and images coupled with the need for very low power consumption, size and weight.”

So, just how is Maplebird planning to make products that stand out in the face of such competition? The company’s principle, outlined Smith, is the smaller the better. Miniature drones have many advantages, he stressed, including reducing regulatory hurdles. They’re also safer for cities in tasks such as monitoring buildings or traffic, and they’re fast and easy to deploy.

The company has been using biomimetic principles in the development of its technology. One of the most fascinating is a practical engine, designed to power flapping wing flight at the insect scale. In order to mimic this to the highest degree, they’ve even used the wings of real bees.

No insects were killed in the process of carrying out their experiments, Smith assured the audience; the bees concerned died of natural causes.

A world of opportunities

Altruistic applications, smart city opportunities and a game of table tennis with a robot were features of other presentations. With so much to impart, coordinator Phil Williams from the Knowledge Transfer Network’s Robotics & Autonomous Systems Group was forced to keep question and answers sessions brief.

Leka’s Moti was the winner of Robohub’s 2014 Robot Launch competition.

Trevor Dowling of Greenwich City Council spoke of the need for robotics in the cities of the future; Nikos Pronios, Lead Technologist at Innovate UK, outlined funding opportunities; Ladislas de Toldi, CEO of Leka, impressed with his desire to help autistic children achieve their potential with the aid of robotics; and Jan Peters, a Professor working with Intelligent Autonomous Systems at the Technische Universitaet Darmstadt, showed the audience his team’s progress with artificial intelligence in the learning of complex tasks such as table tennis.

“A key bottleneck in manufacturing is the high cost of robot programming and slow implementation,” he said. However, “motor skill learning is a promising way to avoid programming all possible scenarios and continuously adapt to the environment.”

He made reference to research from Bosch, which has established that: “If a product costs less than 50 euros or is produced less than 10,000 times, it’s not competitive with manual labour” and pointed out that the robotics market in manufacturing is still at a relatively early stage. “Industry,” he emphasised, “is just starting to profit from this work!”<

Game changing collaboration

A major focus of the forum was that collaboration between industry and academia is vital to fully exploit the opportunities on offer. Two presentations in particular demonstrated how their potentially game-changing collaboration threatens to give Dyson and Apple a run for their money.

The partnership between Sheffield University academic Tony Prescott, Director of the University’s Centre for Robotics, and established designer Sebastian Conran is possibly unique to the field, with Prescott bringing the power of decades of research into human-robot-interaction and Conran brand-conscious design know-how.

Prescott was keen to point out that robots, although they have powerful applications to assist the elderly and infirm, should never be viewed as people substitutes. Instead he likened them to facilitators. One example of this, he said, is in encouraging social interaction among people. To illustrate his point, he indicated a furry bundle on the table: Paro, a Japanese robot resembling a baby seal, which has long been used in care homes and has proved very popular among residents.

In reference to studies that have highlighted the fears and preconceptions people have about robots’ involvement with the elderly and young, he pointed out that the way the questions had been phrased was an important factor. Turning to philosophy and psychology, his intrinsic message was that there are a number of different selves, robots haven’t yet mastered many – if any of them – yet and certainly won’t be taking over the world anytime soon.

But he maintained that in order to satisfy humanity, it is important that robots develop human-like traits. “Empathy,” he said ‘is very useful, to enable them to see the human perspective’.

Although Prescott is currently involved in a number of projects – including WYSIWYD a major EU-funded study to create a new transparency in human robot interaction – his collaboration with Conran took centre stage here. The duo are in the process of forming a startup to commercialise their work.

From here, Conran took up the baton, outlining products the team have been working on, such as MiRo – a mimetic robotic companion, which is a teachable ‘digital pet’. The device sells for around £400, with costs kept low by self assembly. It was important, says Conran, that HRI design principles were considered and he gives the example of blinking, which has been shown to have great impact on user experience.

Delving into the design process behind other products in the pipeline, such as iHelp or MIA (Mobile Intelligent Appliance), Conran explained that he had tried to think in terms of “what if Steve Jobs designed a robot?”

But perhaps the most original of the pair’s designs is the intelliTable. Part funded by an Innovate UK grant, it’s not so much a robot as a gesture- or voice-activated, self-navigating and self-adjusting platform that sees through optical navigation, not dissimilar to Dyson’s vacuum cleaning robot.

Conran believes its applications are diverse: the device can deliver things, act as a shopping trolley or work table. A telepresence screen gives additional functionality and there’s the possibility that, in future, it may also feature a mechanical arm.

The device has had a very good reception, says Conran. There’s been plenty of interest from hotels, for instance, and it’s easy to imagine it being used in hospitals.

Production of the intelliTable is imminent and the team have sourced an ex Ford/Nissan factory for the mechanical development. With the material costs estimated at £1300, the product is expected to retail at around £2500.

Enthusiasm and edutainment

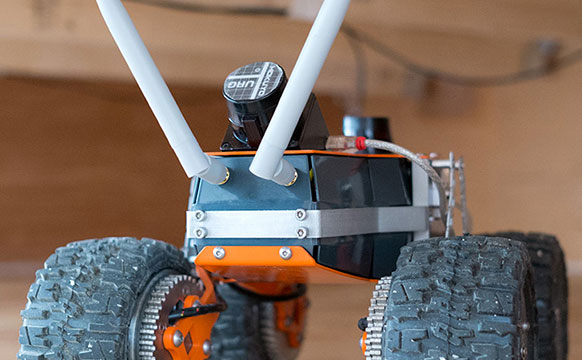

Reach Robotics dubs its Mecha Monsters as the “world’s first gaming robots.”

Aiming at a different market sector and retailing for considerably less, was another product nearing its commercial goal. Silas Adekunle and his team at Reach Robotics believe they have designed the world’s first robotic game system. Dubbed Mecha Monster, the device launches on IndieGogo in November and Adekunle believes it’s truly unique as a programmable toy which you can learn with while creating and having fun through play.

To date, his product had won funding from 11 different sources, “Money,” he said, “creates money. Getting over that first hurdle, so that you can start prototyping, is the hardest part.”

By 2016, he predicts there will be a massive surge in edutainment robotics, with “robot this, robot that – everyone will slap a label on it.”

But Adenkunle is planning to be in the vanguard. A young developer working out of the University of the West of England’s (UWE) Bristol Robotics Laboratory Incubator, his enthusiasm for robotics was palpable. “It’s a very exciting time,” he said, finishing his presentation. Many in the room would certainly agree with him.

This article was originally published on RAS SIG – the Robotics and Autonomous Systems Special Interest Group – part of Innovate UK’s Knowledge Transfer Network.

tags: c-Events, cx-Business-Finance, startups, UK