Robohub.org

Digital farms are already a reality

Source: Nesta.org, Precision Agriculture

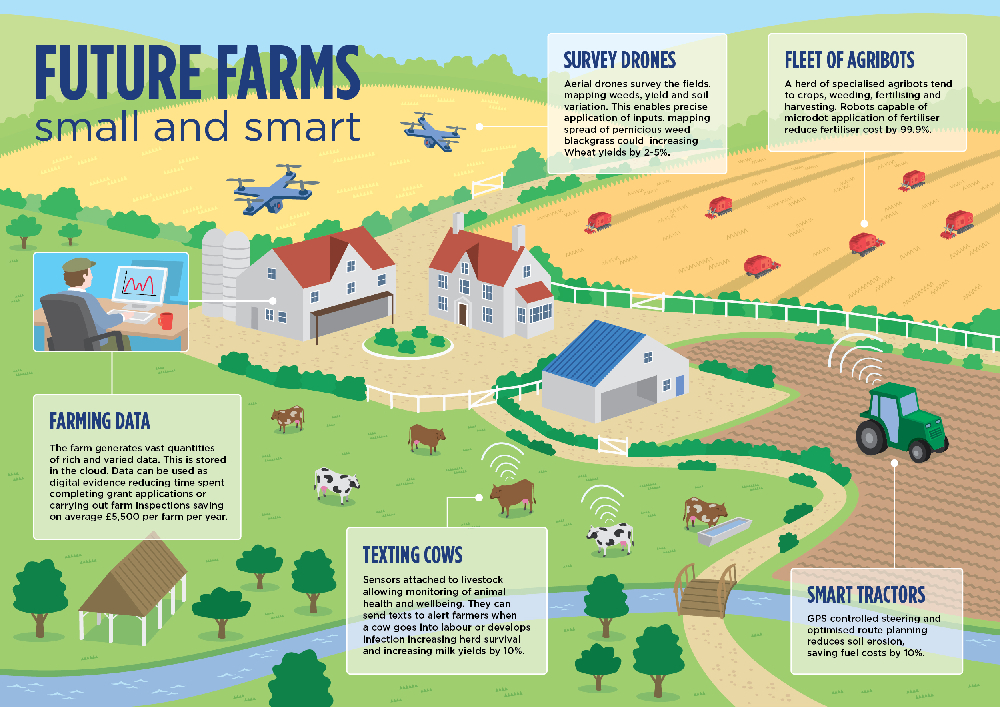

Farmers, ranchers and growers the world over are transitioning to precision agricultural methods, i.e., subdividing their acreage into many unique sub-plots — in some cases right down to the individual plant, tree, or animal — thereby enabling increased productivity, trace-ability and lower overall costs. Low-cost aerial vehicles, sensors and cameras are integral to the process and are being used to map, observe, sense and spray.

Digital farms are already a reality

Robotic automation is already widely practiced and can be seen today in milking systems and increasingly in precision techniques that use sensors and drone-mounted cameras to steer tractors and to monitor soil for temperature, moisture, disease, varmints, crop quantity, weather damage, and nutrient content. This data is then analyzed in order to improve decision-making on planting, weeding, pruning and chemical application. Digitally-controlled farm implements are already in use in developed countries and most Western farmers and ranchers are high-tech to some extent and more variable-rate dispensing devices are on the horizon. Self-steering kits can be found in most new tractors and follow RTK/GPS and digital guidance with levels of accuracy down to the centimeter level.

There are partially and fully automatic and robotic devices for most aspects of agricultural functions from grafting to planting, from harvesting to sorting, from packaging to boxing, but because the metrics of their implementation have thus far been too costly, and the safety and liability aspects difficult, so they are not widely deployed. These challenges are being met with a new group of vendors, lower costs, and new robotic products, often marketed in the form of Robotics-as-a-Service (RaaS). Adding to these challenges are ever-increasing costs and lack of available water, labor and tillable land.

I observed an example of those additional challenges on a recent research trip to Odense, Denmark.

EGATEC A/S specializes in automated end-of-line packaging and palletizing solutions. They are an integrator. Rosborg Denmark is a nursery that grows and sells miniature flowerpots and spices. Rosborg is one of EGATEC’s clients and the two are working together to automate Rosborg’s end-of-line packaging process – a step that presently handles 12 million plants per year and which is done entirely by hand by 40-60 people.

Rosborg is already mechanized. They’ve automated their potting and seeding operations. Plants then are placed on mobile trays slowly moving towards the harvesting stations where fully-grown plants are picked, wrapped and packaged for boxing and palletizing. These latter steps are done by hand and are the steps being automated by EGATEC.

Many of Rosborg’s employees are immigrants eager for the work even though, by Danish standards, it is low paying. In Denmark non-citizens are subject to the same mixture of union and other agreements as citizens and thus their hourly wage approximates $20 an hour — quite high and easy for a robot packaging cell to beat.

Transformative effect on agricultural automation

Unmanned aerial vehicles (UAVs) (drones) are stimulating this transformative effect on agricultural automation. UAVs are beginning to be used in areas as diverse as soil and field analysis, planting, crop spraying and monitoring, irrigation and plant and crop health assessment. They are producing valuable data enabling farmers to make better decisions.

However, amid the current shift toward precision agricultural practices, farmers are also running into hurdles with technology integration. Farmers often have to mix precision ag hardware and software with third-party vendors; the results can lead to lost time from a variety of reasons. To combat these barriers, many farm equipment conglomerates are upgrading their products and offering consolidation software. For example, Trimble Ag Software promises to seamlessly integrate with its hardware solutions as well as with other third-party manufacturers using Trimble’s API. By using one technology platform, data can flow wirelessly across the entire farm. This provides timely crop input recommendations and eliminates data re-entry, saving time and reducing potential errors.

Trimble’s Ag Software, like many others, is attempting to be an all-in-one tool offering customers a complete desktop, web-based and mobile-enabled agricultural software solution for farmers and their stakeholders: farm managers, supervisors, crop advisors, service providers, ag retailers and food processors.

Agricultural Robotics: 149 Profiles

Working together with Tractica, a Colorado research firm, my team and I compiled a list of over 200 global businesses and agencies involved in developing robotic solutions for the ag industry. From that list, I was able to interview and profile over 149 companies and 16 research labs as follows:

- Academic and research labs (16)

- Backroom and post processing (5)

- Dairy and milking (10)

- Drones, analytics and data service providers (26)

- Farm equipment manufacturers (13)

- Harvesting, weeding and thinning robots (21)

- Hobby farming (2)

- Indoor and vertical farming (23)

- Integrator, distributor and reseller (20)

- Self-driving vehicles (15)

- UAS/UAV vendors (14)

This research report will be published in the next few weeks and will contain the whole list, the profiles, and the conclusions drawn from the research, interviews and analyses. The report will be $4,200 for a Basic License (1-5 users) or $6,300 for an Enterprise License. Note: the link to the report is to the previous report and will be updated with new information just as soon as the report is published.

If you enjoyed this article, you may also enjoy these articles about agricultural robotics:

- Swarms of precision agriculture robots could help put food on the table

- Agricultural robot market anticipated to reach $16.3 billion by 2020

- Top 10 technologies in precision agriculture

- Robohub Digest 09/16: AI100, RoboLaw, sailing and farming robots

- In agriculture, robots replace job vacancies

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: agricultural robotics, c-Environment-Agriculture, Frank Tobe, robohub focus on agricultural robotics