Robohub.org

Cable-driven parallel robots: Motion simulation in a new dimension

Source: Max Planck Institute for Biological Cybernetics (MPI), Fraunhofer IPA

To date, cable-driven parallel robots have been used in production environments, where they meet high requirements. The systems surpass conventional industrial robots in size and payload by between one and two orders of magnitude. The end effector can be freely moved with high accuracy by up to eight cables and winches. Based on this technology and in a world first, the idea of a cable-driven motion simulator has now been realized under the lead of Professor Heinrich Bülthoff from MPI for Biological Cybernetics.

Technical innovations

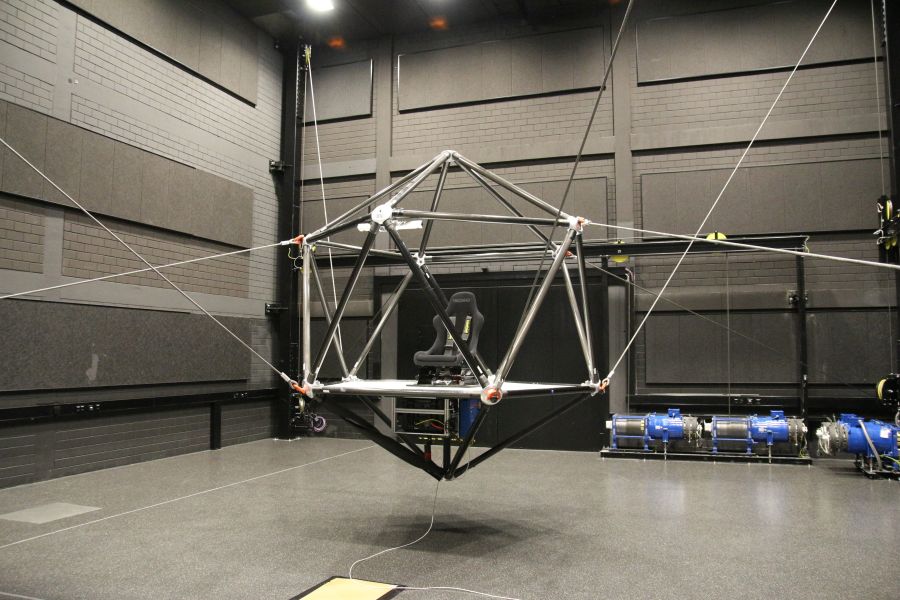

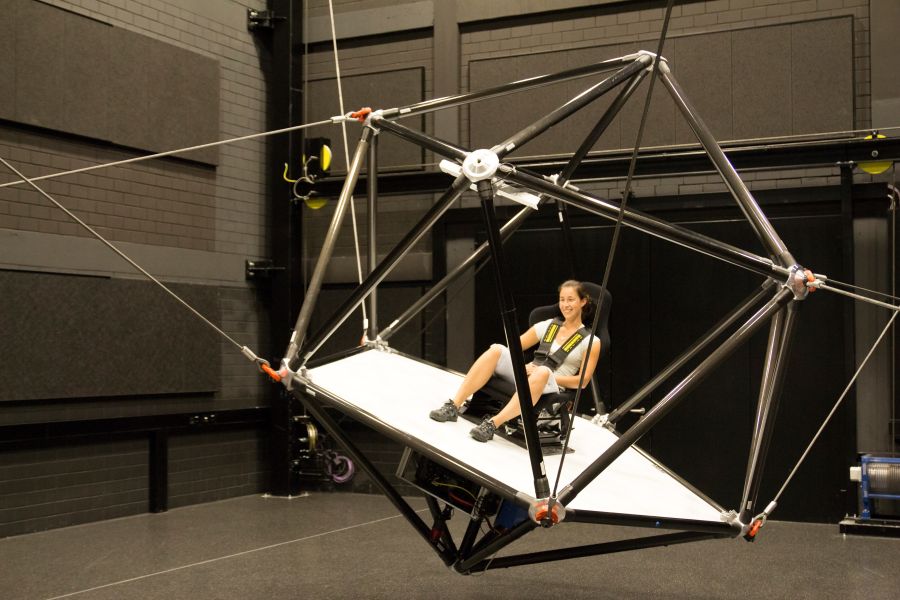

In the cable-driven simulator, the motion of the simulator cabin is controlled by eight unsupported steel cables attached to winches. In contrast to conventional motion simulators, the use of cables makes it possible to reduce the moving mass and to scale the workspace to any required size. A total drive power of 348 kW allows the cabin to accelerate at 1.5 times gravitational acceleration along freely programmable paths inside a 5 x 8 x 4 m³ workspace. In addition, the cables can be reattached in under an hour to enable the simulator to be adapted to different cabins and thus used for a range of scenarios.

During the two-year collaboration between both Institutes, Philipp Miermeister, a member of Fraunhofer IPA’s Cable-driven Robotics working group headed by Junior Professor Andreas Pott, has contributed much know-how to driving forward the design and realization of the simulator. The scientists have not only implemented the control algorithms, but also developed a lightweight yet rugged carbon fibre cabin capable of withstanding the high dynamic loads during operation. Made entirely from carbon fibre tubes, the cabin frame maximizes the usable cabin volume with a diameter of 260 cm for projection surfaces and cockpit instrumentation. This allows it to be used for high-quality video projections and realistic operator interfaces. At the same time, the light 80 kg frame is capable of accelerating at high speed while also withstanding high forces, because, in operation, the cables pull on the outer structure with up to 1.5 tonnes.

The CableRobot Simulator as VR platform

Its large workspace and dynamic capabilities make the simulator suitable for a wide spectrum of VR (virtual reality) applications, including driving/flight simulation as well as investigation of basic perception processes in humans. “This simulator offers us entirely new possibilities for studying motion perception with possible applications in neurological research into balance disorders,” says Professor Bülthoff, who is a long-time perception researcher.

The CableRobot Simulator can be used in combination with different VR solutions such as Oculus Rift or HTC Vive. Depending on the simulation scenario and available space, the smallest version of the robot fits in a room with 5 x 5 x 5 m3. Optimal results will be achieved with a system of 10 to 15 m frame length. There are as good as no limits regarding the size and application range of our simulator. With the current system it is already possible to set up a system for rooms with more than 20 m edge length”, says Miermeister.

Source: Max Planck Institute for Biological Cybernetics (MPI), Fraunhofer IPA

The cabin uses a very flexible structure which provides a spherical internal space which currently is used to mount a race seat, computer systems for visualization, and an additional motion tracking system. The additional tracking system is used to separate the head acceleration signal of the Oculus Rift from the acceleration signal of the cabin. “Currently we are implementing an additional rotation unit inside the cabin which allows us to rotate the seat independently and gives us more flexibility with regards to possible simulation scenarios” explains Philipp Miermeister. The first use case for the extended cabin design will be a realistic helicopter hover trainer, which allows 1:1 mapping of real flight data to the simulator workspace.

Specialized Software

The CableRobot simulator is controlled by a motion cueing software developed at the Max-Planck-Institute, which allows to replicate the motion from a simulation most accurately. It is also possible to use motion cueing and simulation software form third party providers, or to use the system for motion based cinematic experience. “Recently we started to work on motion reconstruction for 360° 3D footage using the optical flow information from the video stream”, mentions Miermeister. This technique allows reconstructing the camera trajectories for movies whose motion data is not available.

Through the linkage with computer games, such as race and flight simulations as well as 360° 3D videos, it is possible to use the CableRobot simulator for the presentation of highly diverse content. Currently a portable solution is developed which allows to set up the modular and lightweight motion simulator at different locations.

tags: c-Research-Innovation, fraunhofer IPA