Robohub.org

‘Tailsitter’ flying robot hovers and recovers easily thanks to new algorithm

Tailsitter in the Flying Machine Arena. Source: Robin Ritz, Institute for Dynamic Systems and Control, ETH Zurich.

In August 2014 Google [x] announced that they had been secretly developing a drone delivery program to rival Amazon’s Prime Air. Called Project Wing, the system was based on a mechanically simple “tailsitter” design – a hybrid vehicle that takes off vertically like a multirotor but is also able to fly horizontally like a fixed-wing airplane. Following field tests, however, Google scrapped the design, saying that it was difficult to control and didn’t perform well in high winds. Since then, researchers at ETH Zurich have developed a new algorithm for robustly controlling a tailsitter flying machine in hover position. Using the algorithm, the tailsitter is able to recover from any orientation, including upside down. ETH has not yet demonstrated its algorithm in real-world conditions (e.g., high winds, GPS localization, different payload distributions). However, given the robustness of the solution shown in the video, perhaps Google should not dismiss the tailsitter design too quickly for its next design iteration.

– Robohub Editors

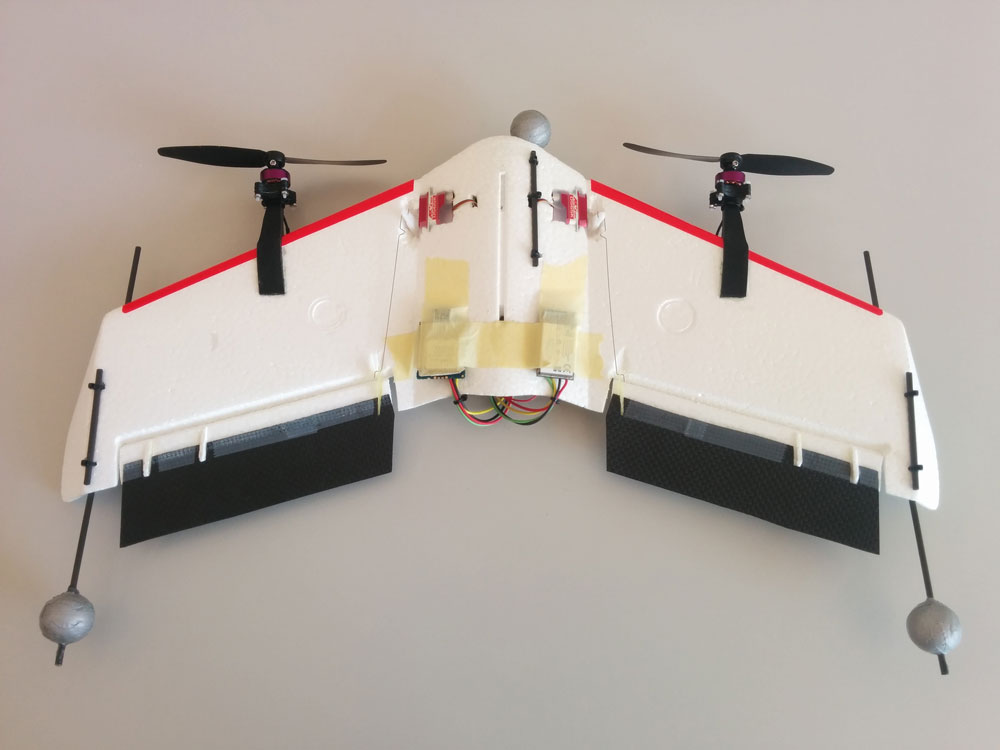

A tailsitter provides hover capability by pointing the nose and thrust direction upwards. For fast forward flight, the vehicle tilts to a near-horizontal orientation, resulting in efficient lift production due to the conventional wing design. Compared to other fixed-wing, hover-capable aircraft such as tiltrotors and tiltwings, the major advantage of a tailsitter is its mechanical simplicity: no mechanism for changing the direction of the propulsion system has to be added, saving weight and increasing reliability.

The algorithm demonstrated in the video is based on Optimal Control. Optimal trajectories for a set of initial orientations are precomputed and the corresponding initial desired body rates are stored in a small lookup table (500 entries). An outer control loop running at 50 Hz reads the desired body rates for the current orientation from the lookup table, and feeds them to an inner control loop. The inner control loop runs at 1000 Hz and tracks the desired body rates with the two propellers and the two flaps using feedback from a rate gyroscope. The resulting real-time computational complexity is extremely low.

Tailsitter’s propellers and motors. Source: Robin Ritz, Institute for Dynamic Systems and Control, ETH Zurich.

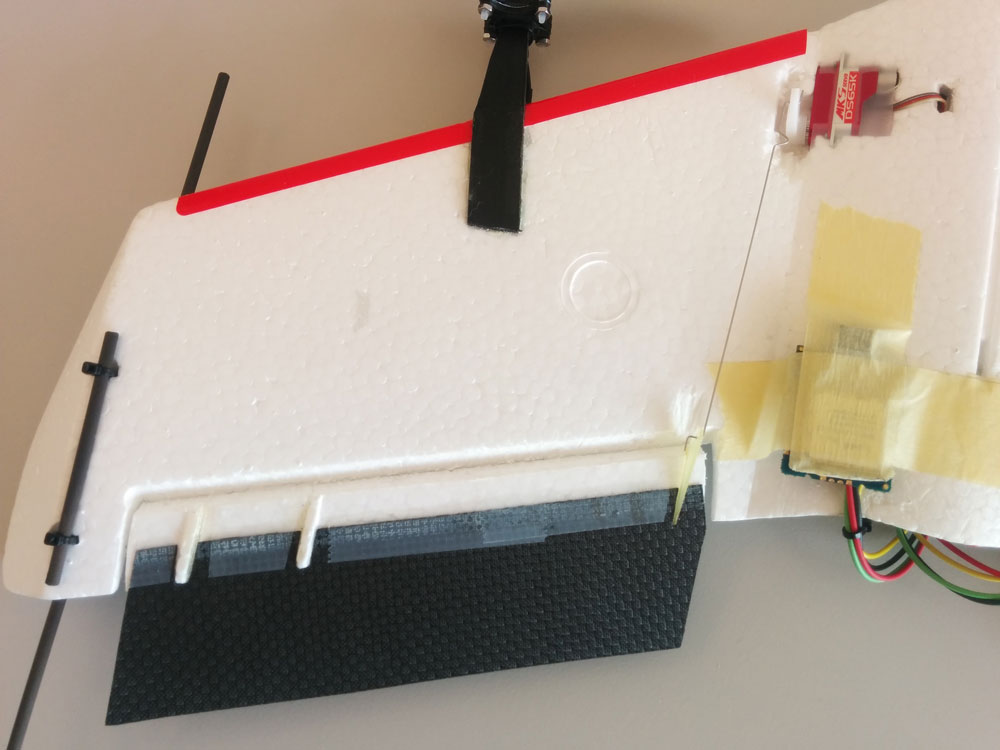

The propellers are driven by brushless Hacker A05-13S motors that are attached to the wings by 3D-printed mountings. While the vehicle is hovering, it is crucial that a large part of the flaps are within the propeller-induced airstream, in order to keep the flaps effective and the system highly maneuverable. The motors are controlled by ZTW Spider 12A ESCs, which run custom SimonK firmware that enables a fast response to thrust set point changes. Since the custom SimonK firmware is tuned for the fastest possible response, the motor controllers get quite hot and are therefore placed in the propeller airstream for cooling.

Tailsitter’s underbelly. Source: Robin Ritz, Institute for Dynamic Systems and Control, ETH Zurich.

Two radios are attached on the bottom side of the vehicle; a WiFly module for high-bandwidth telemetry, and a low-latency, frequency-hopping 2.4 GHz radio link that receives the control commands from the ground station. The total system latency including the motion capture system and the radio link is around 35 milliseconds.

Tailsitter’s flaps. Source: Robin Ritz, Institute for Dynamic Systems and Control, ETH Zurich.

The flaps are actuated by MKS DS65K servos providing a fast response on flap angle changes. The flaps of the original frame are designed for fixed-wing forward flight and do not provide enough control authority for the hover flight regime. Therefore their area is enlarged by carbon fibre sheets. This increases the effectiveness of the flaps by a factor of four. The maximum flap deviation is 30 degrees.

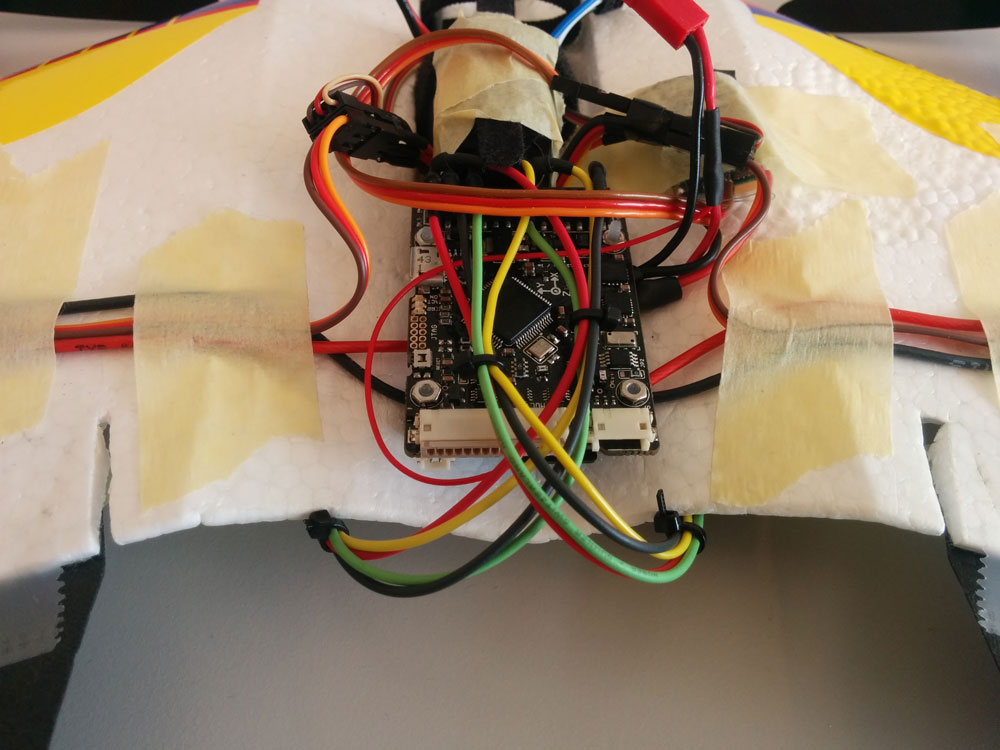

Tailsitter’s flight management unit (FMU). Source: Robin Ritz, Institute for Dynamic Systems and Control, ETH Zurich.

A Pixhawk PX4 Flight Management Unit (FMU) runs the onboard control loop that tracks the desired body rates using a rate gyroscope which is also provided by the FMU. Safety routines that switch off the actuators if the vehicle does not receive control commands anymore or if the battery voltage is too low are also implemented on the FMU.

The algorithm is presented in research paper “A Global Strategy for Tailsitter Hover Control”, submitted to International Symposium on Robotics Research (ISRR), 2015.

Researchers

Robin Ritz and Raffaello D’Andrea

Institute for Dynamic Systems and Control, ETH Zurich

Flying Machine Arena

Technical details

Frame: Robbe Mini Wing RC styrofoam airframe

Electronics: Pixhawk PX4 Flight Management Unit

Battery: Thunder Power RC G6 Pro Lite 25C LiPo 350mAh 2S

Motors: Hacker A05-13S

Motor controllers: ZTW Spider 12A ESCs with SimonK firmware

Propellers: 5×3 GWS EP-5030

Flap servos: MKS DS65K

Infrastructure: Flying Machine Arena

If you liked this article, you may also be interested in:

- Multiple tethered quadrotors whip around a pole together at high speeds

- Quadrocopter failsafe algorithm: Recovery after propeller loss

- Three new quadrotor videos demonstrate agile control and the power of machine learning

- Video: Quadrocopter learns from its mistakes, perfects slalom air racing

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: Algorithm Controls, c-Aerial, cx-Research-Innovation, ETH Zurich, Flying Machine Arena, project wing, Switzerland