Robohub.org

3-D printing hydraulically-powered robots, no assembly required

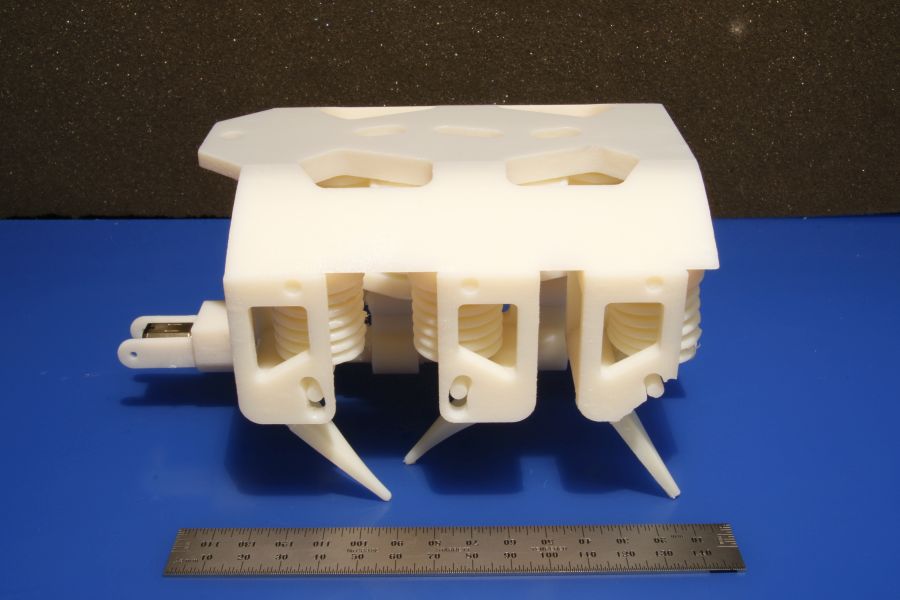

This 3-D hexapod robot moves via a single motor, which spins a crankshaft that pumps fluid to the robot’s legs. Besides the motor and battery, every component is printed in a single step with no assembly required. Among the robot’s key parts are several sets of “bellows” 3-D printed directly into its body. To propel the robot, the bellows uses fluid pressure that is translated into a mechanical force. (As an alternative to the bellows, the team also demonstrated they could 3-D print a gear pump that can produce continuous fluid flow.)

Photo: Robert MacCurdy/MIT CSAIL

By Adam Conner-Simons | CSAIL

One reason we don’t yet have robot personal assistants buzzing around doing our chores is because making them is hard. Assembling robots by hand is time-consuming, while automation — robots building other robots — is not yet fine-tuned enough to make robots that can do complex tasks.

But if humans and robots can’t do the trick, what about 3-D printers?

In a new paper, researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) present the first-ever technique for 3-D printing robots that involves printing solid and liquid materials at the same time.

The new method allows the team to automatically 3-D print dynamic robots in a single step, with no assembly required, using a commercially-available 3-D printer.

“Our approach, which we call ‘printable hydraulics,’ is a step towards the rapid fabrication of functional machines,” says CSAIL Director Daniela Rus, who oversaw the project and co-wrote the paper. “All you have to do is stick in a battery and motor, and you have a robot that can practically walk right out of the printer.”

To demonstrate the concept, researchers 3-D printed a tiny six-legged robot that can crawl via 12 hydraulic pumps embedded within its body. They also 3-D printed robotic parts that can be used on existing platforms, such as a soft rubber hand for the Baxter research robot.

The paper, which was recently accepted to this summer’s IEEE International Conference on Robotics and Automation (ICRA), was co-written by MIT postdoc Robert MacCurdy and PhD candidate Robert Katzschmann, as well as Harvard University undergraduate Youbin Kim.

The printing process

For all of the progress in 3-D printing, liquids continue to be a big hurdle. Printing liquids is a messy process, which means that most approaches require an additional post-printing step such as melting it away or having a human manually scrape it clean. That step makes it hard for liquid-based methods to be employed for factory-scale manufacturing.

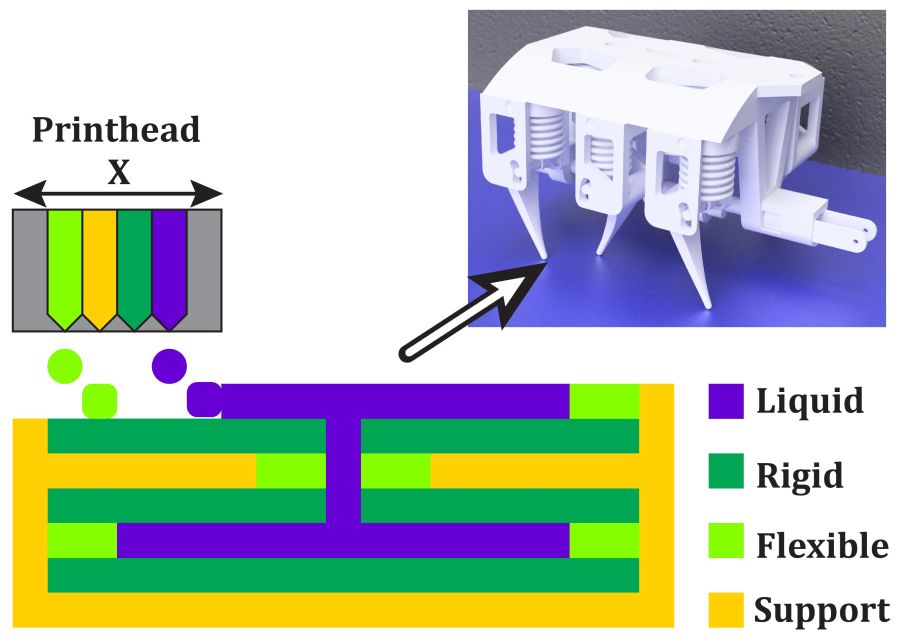

The team’s method of printing solid and liquid materials simultaneously allows them to create robotic structures that can be hydraulically powered.

Photo: Robert MacCurdy/MIT CSAIL

With “printable hydraulics,” an inkjet printer deposits individual droplets of material that are each 20 to 30 microns in diameter, or less than half the width of a human hair. The printer proceeds layer-by-layer from the bottom up. For each layer, the printer deposits different materials in different parts, and then uses high-intensity UV light to solidify all of the materials (minus, of course, the liquids). The printer uses multiple materials, though at a more basic level each layer consist of a “photopolymer,” which is a solid, and “a non-curing material,” which is a liquid.

“Inkjet printing lets us have eight different print-heads deposit different materials adjacent to one another, all at the same time,” MacCurdy says. “It gives us very fine control of material placement, which is what allows us to print complex, pre-filled fluidic channels.”

Another challenge with 3-D printing liquids is that they often interfere with the droplets that are supposed to solidify. To handle that issue, the team printed dozens of test geometries with different orientations to determine the proper resolutions for printing solids and liquids together.

While it’s a painstaking process, MacCurdy says that printing both liquids and solids is even more difficult with other 3-D printing methods, such as fused-deposition modeling and laser-sintering.

“As far as I’m concerned,” he says, “inkjet-printing is currently the best way to print multiple materials.”

The results

To demonstrate their method, researchers 3-D printed a small hexapod robot that weighs about 1.5 pounds and is less than 6 inches long. To move, a single DC motor spins a crankshaft that pumps fluid to the robot’s legs. Aside from its motor and power supply, every component is printed in a single step with no assembly required.

Among the robot’s key parts are several set of “bellows” that are 3-D printed directly into its body. To propel the robot, the bellows uses fluid pressure that is then translated into a mechanical force. (As an alternative to the bellows, the team also demonstrated they could 3-D print a gear pump that can produce continuous fluid flow.)

Photo: Robert MacCurdy/MIT CSAIL

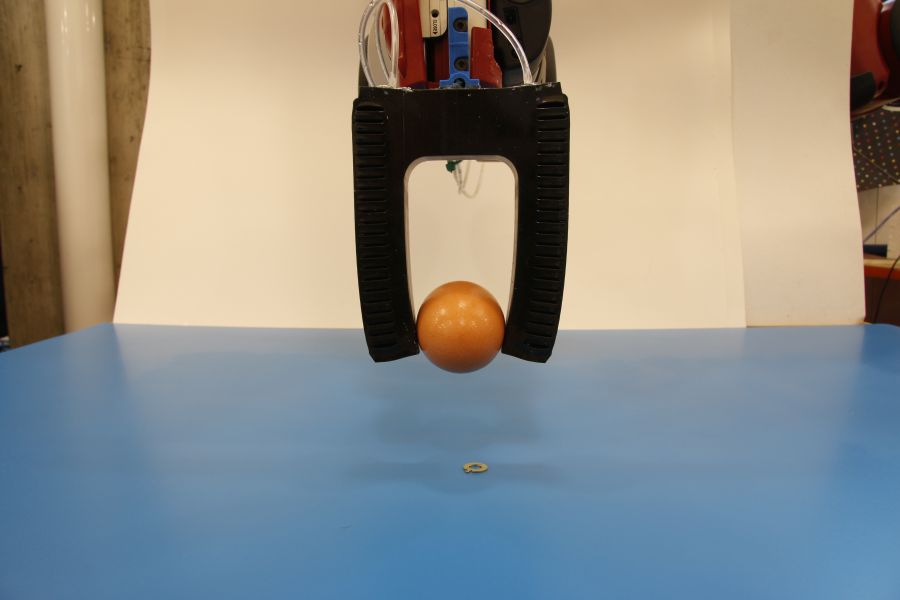

Lastly, the team 3-D printed a silicone-rubber robotic hand with fluid-actuated fingers. This “soft gripper” was developed for Baxter, a robot that was designed by former CSAIL director Rodney Brooks as part of his spinoff company Rethink Robotics.

“The CSAIL team has taken multi-material printing to the next level by printing not just a combination of different polymers or a mixture of metals, but essentially a self-contained working hydraulic system,” says Hod Lipson, a professor of engineering at Columbia University and co-author of “Fabricated: The New World of 3-D Printing.” “It’s an important step towards the next big phase of 3-D printing — moving from printing passive parts to printing active integrated systems.”

Compatible with any multimaterial 3-D inkjet printer, “printable hydraulics” allows for a customizable design template that can create robots of different sizes, shapes and functions.

“If you have a crawling robot that you want to have step over something larger, you can tweak the design in a matter of minutes,” MacCurdy says. “In the future, the system will hardly need any human input at all; you can just press a few buttons, and it will automatically make the changes.”

MacCurdy envisions many potential applications, including disaster relief in dangerous environments. Many nuclear sites, for example, need to be remediated to reduce their radiation levels. Unfortunately, the sites are not only lethal to humans, but radioactive enough to destroy conventional electronics.

“Printable robots like these can be quickly, cheaply fabricated, with fewer electronic components than traditional robots,” MacCurdy says.

Looking ahead

The team is eager to further build on their work. While the hexapod’s 22-hour print-time is relatively short for its complexity, researchers say that future hardware advances would improve the speed.

“Accelerating the process depends less on the particulars of our technique, and more on the engineering and resolution of the printers themselves,” says Rus, the Viterbi Professor of Electrical Engineering and Computer Science at MIT. “Printing ultimately takes as long as the printer takes, so as printers improve, so will the manufacturing capabilities.”

This isn’t Rus’ group’s first foray into 3-D printed robots. This past fall her team developed a similar gripper, while in 2014 they created an arm that can snake through a pipe and grasp an object. But where these projects still required multiple non-3-D printed objects, “printable hydraulics” gets even closer to printing all components in one step.

“Building robots doesn’t have to be as time-consuming and labor-intensive as it’s been in the past,” Rus says. “3-D printing offers a way forward, allowing us to automatically produce complex, functional, hydraulically-powered robots that can be put to immediate use.”

The team’s work was funded, in part, by a grant from the National Science Foundation.

tags: Artificial Intelligence, c-Research-Innovation, Computer Science, Computer Science and Artificial Intelligence Laboratory (CSAIL), robotics, robots, School of Engineering, soft robotics