Robohub.org

42 companies empowering robots and humans to work side-by-side

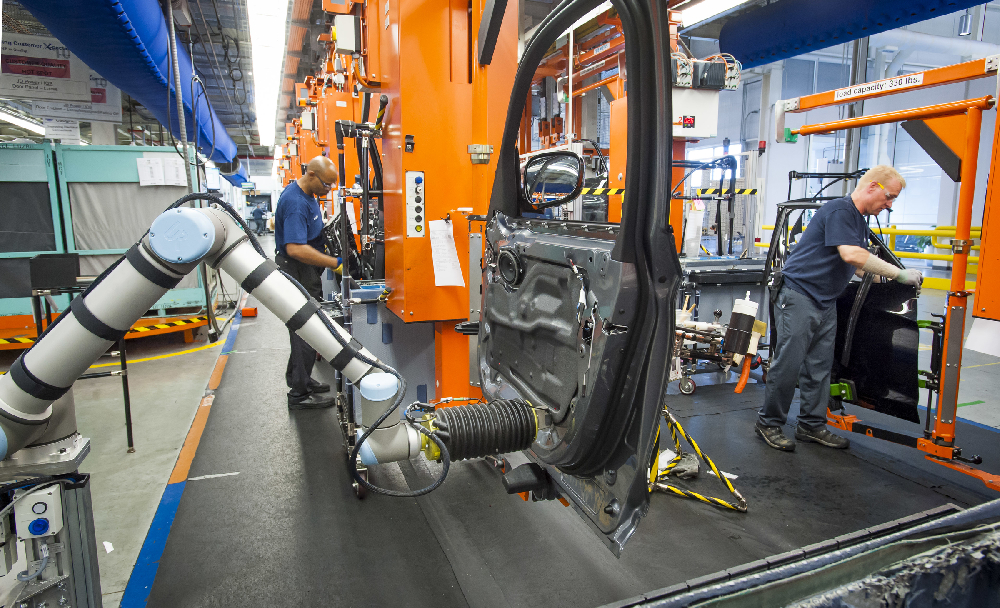

There is growing demand for more flexibility in factories and shops. Collaborative robotics, a sub-set of service robotics in labs, manufacturing and material handling, is where the action is today because co-bots are meeting these new demands, while caged legacy robots are not.

Service and assistance robotics, with and without mobility, are an emerging and somewhat futuristic field, albeit one which is developing rapidly. Vision and tactile sensors, safety features, mobility, and simple, fast and intuitive robot training, are all playing important roles in many application areas.

As robots can be trusted to safely work alongside humans and are relatively portable and easy to program, business managers, from all sized companies, begin to imagine uses within their labs, facilities, factories and shops – uses where robots and humans collaboratively work together to improve productivity and efficiency by using the robot where it is better than its human partners, and vice versa.

Definitions, features and applications

The objective of collaborative robotics is to combine the repetitive performance of robots with the individual skills and abilities of people. People are better at seeing and solving imprecise situations; robots can be more precise, powerful, and perform longer.

Wikipedia says a cobot or co-robot (from collaborative robot) is a robot intended to physically interact with humans in a shared workspace. This is in contrast with other robots, designed to operate autonomously or with limited guidance, which is what most industrial robots do. Cobots can have many roles — from autonomous robots capable of working together with humans in an office setting that can ask for help, to industrial robots having their protective guards removed as they can react to a human presence under EN ISO 10218 which requires the robot or robot application comply with one of four collaborative modes: Safety-Rated Monitored Stop; Hand Guiding; Speed and Separation Monitoring; and Power and Force Limitation.

Most of these new co-bots share a growing list of features:

- Affordable cost

- Plug and play

- Intuitive programmability

- Narrow width

- Precise movements as good or better than a human

- Safe to work alongside

- Complies with ISO 10218 and/or ISO 15066

- ABB launched SafeMove2, a software sensor suite that, when activited, makes their robots human-safe.

- Human safe isn’t necessarily collaborative

- Speedy movements as good or faster than a human

- Portability

- ROS

Co-bots are emerging in a variety of verticals:

- Security and surveillance

- Loading/unloading and material handling

- Quality control, testing and measuring

- Guides and sales assistance

- Consumer products

- Industrial tasks (such as):

- Pick and place

- Assembly

- Machine tending

- Polishing, sealing and deburring

- Gluing, dispensing and welding

- Handling and packaging

Numbers

Trade shows tend to feature business solutions 5-10 years ahead of their actual deployment. Bin picking was the trend 10 years ago at robotics trade shows. For the last 5 years, collaborative robotics has been prominently displayed and demonstrated, and the numbers and forecasts showing up in research reports are beginning to prove that the trend is emerging and the collaborative segment of the robotics industry is growing exponentially. In their 2017 Worldwide 10 Robotics Predictions report, IDC said:

Prediction 7: Collaborative Robots — By 2018, 30% of all new robotic deployments will be smart collaborative robots that operate three times faster than today’s robots and are safe for work around humans.

- Transparency Market Research, in their January 2017, 147-page analysis which costs $5,795, forecast that the co-bot market will be worth $95 billion by the end of 2024 and will be growing at a compounded annual growth rate (CAGR) of 30% from now until then.

- Research and Markets, in a November 2016 165-page report costing $3,999, forecast that collaborative industrial robot sales will reach $2 billion by 2021 at an annual CAGR of more than 60%.

- Markets and Markets, in their August 2016, 157-page report which costs $5,650, also forecasts a high CAGR: 60% between 2016 and 2022.

(UR) reflects those phenomenal growth figures. Annual sales have risen from $10 million in 2012 to $95 million in 2016 with revenue expected to be $140 million in 2017.

Beginning from 2017, however, competition will become more prevalent on many fronts from a variety of emerging co-bot companies described below.

Industrial co-bot makers

Most SME’s have a low cost threshold for capital expenditures like robots, thus pricing is a serious consideration. ROI (return on investment) is also important. Universal Robots started a clever advertising campaign using videos showing application use cases and prominently featuring the payback period – from as little as 3-4 months to a year; very respectable in ROI terms. Consequently the wide range of prices for co-bots is most often tempered by the use case(s), ease of use, and ROI. Prices begin at $3,000 for the Chinese-made Dobot, to $11k for the new German Franka, to $29k for an American Sawyer, $35k for a Danish UR10, all the way to $60k for Swiss ABB’s YuMi and up to $100k for Germany’s Kuka LBR iiwa.

Listed below are current and soon-to-launch co-bot providers. This is a moving target, i.e., there are new companies popping up each day. I’m sure to find and add new ones after my trip to Automate/ProMat in Chicago next week. Follow the company/product links to get detailed technical specifications.

| Company/Product | Description/Story | Year entered marketplace |

|---|---|---|

| ABB Roberta 4, 8 and 12 |

The Gomtec Roberta one-armed robot was a hit at the 2014 AUTOMATICA trade show in Munich. Inventor Bernd Gombert, entrepreneur, and holder of more than 100 patents, left the German Aerospace Center to start Gomtec and then displayed dozens of his new robots at the show to overflowing crowds. The suggested price was low and competitive, the design was sleek, and the software was intuitive and easy. In early 2015, ABB acquired Gomtec and withdrew Roberta from the market saying they needed time to incorporate it into the ABB brand and coordinate the differences in the software. Rumors suggest that 3 versions of the re-branded Roberta – or whatever its new name becomes – will be launched in 2017 but ABB insiders know nothing and are saying even less, particularly whether the software will be old school (like the YuMi) or new. | 2017 |

| ABB YuMi |

ABB’s two-armed YuMi robot was officially launched mid-2015. FRIDA, as it was previously named, was field-tested at various automakers for many years before and frequently written up in papers and reviews. The new name, YuMi, stands for “you” and “me” collaboratively working together. Nevertheless, YuMi still depends on ABB’s legacy programming language and teach pendant making it unattractive to SMEs and companies that don’t already deploy ABB robots and have a legacy programming staff. | 2015 |

| AUBO (Smokie) i5 |

Except for coloring, the AUBO i5 robot looks like – and has almost identical specs when compared to – Universal Robot’s UR5. Only the price ($10k cheaper than the UR5) and software are different. AUBO’s open software system, with API and ROS support, facilitates secondary software and product development. A cloud platform management system enables remote maintenance, fault diagnosis, and online upgrading. Shipments begin in the summer of 2017. | 2017 |

| Bosch APAS |

Bosch has used their portable APAS robot for internal assembly tasks for many years. They launched it for commercial use in 2014 saying that it was the first mobile co-bot to be certified under the new safety ISOs. It has appeared at recent trade shows configured to provide mobile inspection and testing and as a barista and cotton candy provider at the big Consumer Electronics Show (CES) in Las Vegas. | 2014 |

| Carbon Katia |

Carbon.ai is a San Francisco startup with a low-priced small one-armed robot called Katia (which stands for Kick Ass Trainable Intelligent Arm). At present they are designing their Katia for manufacturing with shipments to begin in Q3 or Q4 2017. | 2017 |

| Comau Racer 3 and 5 |

Launched as optional co-bots using the AURA add-on system, Comau’s Racer 3 and 5 (for 3 and 5 kg payloads), are stylish but, like the ABB Yumi, only offer legacy programming links with an old-school teach pendant making it unattractive to SMEs and companies that don’t already deploy Comau robots. Comau also launched a two-armed cobot called Amico and an AGV, the Agile 1500. | 2016 |

| Denso Cobotta |

Displayed as a prototype at the big Japanese trade show iREX late in 2015, Denso’s sleek, tiny co-bot Cobotta is schedule for delivery in 2017, price unknown. The Cobotta has a payload of just 1 pound and can be configured as both a 1- and 2-armed robot. Whether Denso’s existing suite of robot software for programming the robot will be replaced by more intuitive and simple to use software is unknown. | 2017 |

| Dobot M1 |

This small Chinese-built one-armed robot begins delivery in June, 2017 and sells for $3,000. It can also be configured as a two-armed robot. The specs indicate that it is comparable to the Sawyer co-bot. Dobot has produced and sold cheaper personal use and education robot arms for DIY hobbyists and academia since 2015 and advertises easy to use and intuitive robot training software for the M1. | 2017 |

| Fanuc CR-35iA, 4iA, 7iA and 7iAL |

Fanuc launched a green soft-covered collaborative robot line that can safely handle payloads up to 75 pounds. In addition to the 35 kg CR-35iA robots for heavy-duty machine tending, packaging and palletizing, Fanuc is also offering a 4 kg and 7 kg co-bot for light loads and more narrow work spaces. The CR-robots comply with the new safety standards and comes equipped with push back and other movement tracking capabilities but remain like all other Fanuc robots and requires Fanuc’s old-school interface and teaching pendant. | 2016 |

| Franka Emika | Franka’s $12,150 package of arm, gripper, teaching device and software was heralded as a major breakthrough at last year’s Hannover Messe trade show and from academics worldwide as they begin to receive their research version of the product which recently began shipping. Industrial versions will ship later in 2017. IEEE Spectrum wrote: “Franka has more dexterity than is typical for a robotic arm because it is what is known as a torque-controlled robot. It uses strain gauges to measure forces on all of its seven joints, allowing it to detect even the slightest collisions. The result is that it can perform tasks that require direct physical contact in a carefully controlled manner. These include drilling, screwing, and buffing, as well as a variety of inspection and assembly tasks that electronics manufacturers in particular have long wanted to automate.” | 2017 |

| Han’s Holding Group Elfin |

Han’s Group has made laser cutting and welding robots for a few years but recently introduced their Elfin co-bot to the Chinese market, a very similar robot to the UR5. OMRON, the Japanese automation and healthcare conglomerate, recently signed a strategic robotics partnership with Han’s to develop robotics and co-botics. OMRON also recently acquired Adept Technologies, an industrial and mobile robot maker that doesn’t have a co-bot in their product line. | 2016 |

| JK-Tech JK7 and JK Dual Arm |

A 2012 Beijing startup demonstrating their product for the first time outside China at this year’s Hannover Messe trade show with a 7-axis one-armed robot and a dual-armed robot certified (by them) to be safe and collaborative. JK-Tech had a booth at last year’s Beijing World Robot Conference and trade fair. No info about sales or shipments. | 2017 |

| Kawada (Shinsei) Nextage |

Kawada Shinsei Robotics is a 2013 spin-off from Kawada Technologies. The two-armed Nextage robot was designed for industrial operation but modified to be collaborative over the last few years. Over 200 of the $60,000 robots have been sold and are at work in factories in Japan. In the co-bot version, safety is handled by the stereo vision cameras in the head and by using low-power motors and elbow controls so that they don’t jut outwards even when both arms are in operation. Kawada also makes the HRP humanoid robots. The HRP-2 was used by one of the teams in the DARPA Robotics Challenge held in 2015. | 2014 |

| Kinova Jaco and Mico |

This Canadian assistive robot maker began when two engineers partnered to make the $30,000 Jaco arm and 3-fingered hand to help Jaco, a relative with muscular dystrophy. In 2013, they launched MICO, a smaller, more compact $10,000 less expensive version. | 2016 |

| Kuka LBR iiwa 7 and 14 |

The first production co-bot from one of the Big Four robot makers, Kuka’s LBR iiwa is sleek, stylish, well-built and capable. It represents the Kuka brand well – but expensively. The LBR started off selling for $100,000 but now starts at $60,000 – still higher than all but one of the other competitors. Kuka uses Kuka’s proprietary programming language and teach pendant making it unattractive to SMEs and companies that don’t already deploy Kuka robots and have a legacy programming staff. | 2013 |

| Life Robotics CORO |

This Japanese co-bot maker started delivering to auto companies and other industrial users early in 2016 and, later in the year, raised around $14 million to scale up production. With a compact footprint and ‘elbow-less’ design, CORO is a pick-and-place robot that can safely share workspace and is quite flexible. | 2016 |

| Mabi Robotic Speedy 6 and 12 |

Mabi Robotic is a bit unusual. They have two models, Speedy 6 and 12, which they configure one of three ways: Basic, Professional and Advanced. Basic is not collaborative; Professional and Advanced both have force sensors in each axis which, along with add-on co-bot control software, makes the robot safe for collaboration. Speedy also has an interactive real time and graphical interface. | 2016 |

| Mecademic Meca 500 |

This mini-cobot arm, from a Canadian startup, is more than twice as small as the smallest industrial robot and in no way a toy; it’s built by professionals for professionals in electronics, watchmaking, pharmaceuticals, health, or as a component in third-party products. It fits in a briefcase. It weighs less than 12 pounds and has a payload of one pound. The controller is embedded in its base and the software works from a PC or tablet. | 2017 |

| Modbot | This San Francisco startup has parlayed a novel but relevant concept, modularity, into a functional smart robot arm, but the resulting product is being marketed more toward academics and DIY people than factory and shop people. A co-bot variation is optional but available. | 2017 |

| pi4 Robotics Workerbot MD850 and MD1300 |

pi4 Robotics is a German robot maker and integrator. Their Workerbots, which use UR robots for their arms, have been in the field for a few years but are quite expensive, $70k to $100k. Their Workerbot 3 is collaborative with integrated safety technology. It has an optional camera above the gripper and an optional voice output for progress reports and alerts. | 2015 |

| Precise Automation SCARA, Cartesian and 6X |

The founders of Precise Automation are long-time roboticists dating back to the Unimation PUMA robot and the founding of Adept Technology. Their Cartesian and SCARA robots can be seen in labs around the world. They recently modified some of their robots to comply with ISO 15066 and to provide a complete line of analytical and diagnostic desktop co-bots. | 2016 |

| Productive Robotics OB-7 |

This Southern California startup is launching their OB-7 co-bot at Automate/ProMat with limited quantities available for delivery in 2017. The robot comes equipped with a two-fingered gripper. | 2017 |

| Rethink Robotics Baxter and Sawyer |

In 2008, Rodney Brooks co-founded Heartland Robotics with a goal to produce a low-cost, easily trainable robot for SME use. In 2012 he renamed the company Rethink Robotics and released Baxter, a two-armed robot with a base selling price of $25,000. Brooks used his skills as a colorful and persuasive educator to teach SMEs and the media about the benefits of his new Baxter co-bot. Although Brooks educated and persuaded, Baxter didn’t perform to business standards… but Universal Robots and their UR robots did. Unintentionally, Brooks was benefitting URs sales efforts because he was right: there is a need for human-robot collaboration in SMEs (with the right co-bot). After many corporate ups and downs, in 2015 Rethink launched Sawyer, a one-armed smaller and narrower co-bot meant for electronics assembly applications and, in 2016, established distribution channels in China. In 2017, Rethink upgraded their Intera software to version 5 adding features like simulation, ROS and ROS-I. The new software also enables the robot to control the actions of other machines or devices with which it is connected and may eliminate the need for a PLC. | 2012 2015 |

| Schunk Powerball LWA 4P |

Schunk’s lightweight, battery-powered arm has 3 ERB Powerball modules and 6 DOF. Each module has 2 orthogonally servo axes powered via a precision gear and brushless DC-servo drives and each axis has its own stopping brake. Control is done by ROS or KEBA. Style, precision and efficiency – Schunk’s traditional mantra in the gripper world – are all exhibited in this co-bot. | 2015 |

| ST Robotics R12 5- and 6-axis |

ST Robotics is a British maker of low-cost desktop and lab robots. Training is provided by a traditional teachpad using RoboForth, their version of the Forth language. Safety is enabled by Workspace Sentry, a robot and area safety system based on strategically positioned sensors around the shared worspace. ST also offers a line of grippers for their robots. | 2012 |

| TM Techman | TM Techman is startup subsidiary of a Taiwanese company that makes computer peripherals, Quanta Storage. It is not to be confused with Toshiba Machine which produces many industrial and SCARA robots for the auto, electronics and life science industries but, at the present time, doesn’t have any collaborative products. TM Techman’s co-bot comes equipped with a built-in vision system and vision software for pattern matching, object localization, visual servoing, image enhancement, bar code reading, color classifier, etc. Training can be hand-guided, fine-tuned on a smart phone, and operated from onboard buttons or remotely. | 2017 |

| Universal Robots UR5, UR10 and UR3 |

Universal Robots (UR) formed in 2005 and installed their first co-bot in 2008. Making their robots easy to program was a major focus and they developed an intuitive touch screen and graphical user interface which made it surprisingly simple. Safety was the other major concern and they enlisted the Danish Technological Institute (DTI) to test their new robot. DTI confirmed that it would function in a safe manner without needing to be caged in thus enabling an important sales feature for the new robot. Since their first sale in 2008, sales have grown at 50-80% each year. UR was recently acquired by Teradyne. Teradyne had purchased some UR robots and had firsthand knowledge of their value within their factories. From Teradyne’s point of view, this was a win-win transaction: Teradyne becomes a player in the collaborative robotics space and the inventors and entrepreneurs of Universal got a serious strategic partner, one that could help them with marketing, manufacturing, management and engineering. UR co-bot sales are expected to be around $140 million for 2017. | 2008 2010 2015 |

| Yaskawa Motoman HC10 | The HC10 ensures safety by means of force/torque sensor in every axis. Programming can be performed with the “Smart HUB” manual function. And the HC10 is compatible with the other robots in the Motoman portfolio and features all known benefits in terms of controls and hardware. | 2017 |

End-of-arm-tooling (EAOT) / gripper providers

EAOT too is a moving target with multiple new vendors showing up frequently. The list below, however, is a list of companies that actually produce and market grippers for co-bots now. It doesn’t include vision, tool-changer or sensor providers. Follow the highlighted links to get detailed technical specifications.

| Company | Description/Story |

|---|---|

| Active8 Robots | Active8 Robots makes their own grippers but also resells multiple brands – from dual grippers to vacuum sticks to a 5-fingered hand. They also design and build custom EOAT. |

| Barrett Technology | The three-fingered BarrettHand has been widely used for many years. Its versatility is the main feature and the hand matches the functionality of a wide range of custom grippers by quickly switching part/tool shapes electronically. |

| Chanto Air Hydraulics | Chanto makes low-cost pneumatic parallel, angular, and air grippers for all types and sizes of robots including co-bots. |

| QB Robotics | QB is a 2011 spin-off from the University of Pisa and the Italian Institute of Technology. They make actuators, devices and systems for robotic hands, handles, delta robots and Variable Stiffness Actuators. They also have a 5-fingered soft robotic hand. |

| On Robot ApS | On Robot is a Danish startup attempting to fill the space provided by Robotiq, i.e., as principle supplier of grippers for Universal Robots line of UR robots. Their grippers are simple to use, plug compatible with UR robots and their dual gripper – two independent grippers on a single frame – is proving to be a novel time saving device. |

| RightHand Robotics | Righthand Robotics makes and sells the ReFlex SF and ReFlex TakkTile 3-fingered hands for UR and Rethink Robotics co-bots. RHR is launching its new RightPick gripper which combines a vacuum stick with fingers to quickly pick and grasp individual items. “RightHand Robotics has created a transformative technology combining machine learning and smart hardware to address a tremendous opportunity in the logistics industry,” says investor Andy Rubin, Founder and CEO at Playground Global and formerly head of Google’s robotics group. “For the first time, affordable industrial robots can grasp things they have never seen before.” |

| Robotiq | Robotiq, a Canadian manufacturer with an international reach and a very large following, has been supplying grippers, cameras, vision systems and sensors for UR co-bot and industrial robot buyers since 2008. Their low-cost 2- and 3-finger grippers are standard starter sets for new co-bot customers. |

| Sake Robotics | This Japanese supplier of under-actuated parallel gripping devices uses long-lasting ceramic tendons as the link between the actuators and finger motion and supports all the major brands of co-bots plus industrial robot providers. The under-actuated fingers stay straight when picking up small objects and wrap around larger objects. |

| Schunk | With typical Schunk professionalism, they’ve renamed their line of grippers earmarked for co-bots as “co-act” grippers. The new HRC grippers, Co-act Gripper JL1, EGP, EGN and WSG were presented for the first time in live applications at the Automatica 2016 show and have been selling them ever since. |

| Schmalz | This large Germany-based provider of all things vacuum-related has been providing vacuum sticks and other pneumatic grasping devices for robots for many years, and for co-bots since they first hit the market. |

| Shadow Hand | Shadow Robot has been providing complex robotic hands and prosthetics since 1987. It has developed a wide range of products, some of which are appropriate to be the end-of-arm tool on co-bots. Shadow’s Smart Grasping System with torque sensing has stored intelligence to know what it’s grasping as it is approaching it, and chooses the correct grasp as a result of that foreknowledge. The system is compatible with all Shadow hands for all major brands of co-bots. |

| Soft Robotics | Soft Robotics is a Fanuc integrator and developer of soft-fingered sensitive grasping systems. Their adaptive, plug and play, air actuated soft elastomeric end effectors enable novel industrial applications on all types of robots and co-bots. |

| Weiss Robotics | Weiss Robotics’ servo-electric GRIPKIT-E or smart pneumatic GRIPKIT are easily mounted on UR robot arms. Their URCAPS plug-in integrates into UR’s Polyscope software system. Weiss also offers a wide range of gripping systems, and tactile and force torque sensing devices. |

| Zimmer Group | Zimmer is a German company with a wide range of products for the fields of handling technology, linear technology, and industrial and soft close damping technology. Most of their products and accessories have been adapted to work on UR and other co-bots. |

Resources

- CobotsGuide

- Robotiq

- eBook: Grippers for Collaborative Robots

- eBook: ISO/TS 15066 Explained

- eBook: Collaborative Robot 3rd Edition

- ROS and ROS-Industrial

tags: c-Business-Finance, collaborative robots, industrial robotics, robotiq, robots, soft robotics