Robohub.org

The real soft robots that inspired Baymax, with Chris Atkeson

Baymax, the lovable, inflatable robot star of Disney’s recent hit, Big Hero 6, is far from a movie fantasy. With their soft cushiony bodies, robots like Baymax have very real prospects as future care-givers, space-travellers and more. Robohub’s Helmut Hauser spoke to the man who inspired Baymax – Chris Atkeson, Professor of Robotics at Carnegie Mellon University – about the hard science behind soft robotics.

[HH] Professor Atkeson, can you give us the background – how Disney approached you and how they decided to use a soft robot for the role of Baymax?

[CA] When Disney makes one of these animation movies, they do research. For example, for the movie Frozen, they had a bunch of animators who were from Southern California and had not really experienced snow. They sent a lot of them to Norway to play in the snow there and film it. That led to the movie Frozen.

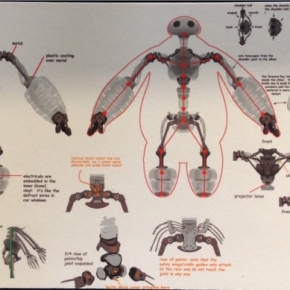

For Big Hero 6, they knew they were going make a movie about a robot. They had the outline for the story from a Marvel comic, but they really wanted a robot that was new and different, they didn’t want a Terminator or a Transformer. So they contacted Disney Research, which tours robot laboratories around the world. One of the laboratories they visited was mine. They saw our work on inflatable robots to help dress, people, feed them and comb their hair, and the Disney folks were very happy because they’d found their robot: an inflatable robot that was very, very different from anything that had been in the movies before. And they also found a character for Baymax – a health or personal care, companion robot.

You are working in the field of soft robotics. Could you please explain what that is?

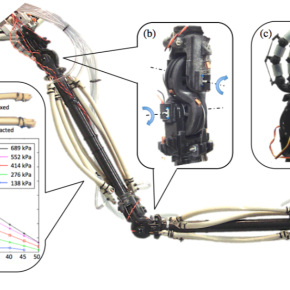

We’d like to have robots help take care of people and trying to do that with a very heavy robot is difficult, because sometimes computers break down or crash and the robot moves in unexpected ways, and sometimes people aren’t very co-operative. When I give a tour of my robotics lab to children, they often try to grab the robot by the legs and [it] could fall down. If a robot is very heavy, let’s say 100-150 kilograms, it can hurt the children or a pet. So I decided the best way to make a robot safe is to make it as light as possible, because mass is what causes gravitational force. Your momentum and your energy are proportional to mass. So, if we can reduce mass, we can reduce force and momentum; we can reduce energy and make it a much safer robot. So I was actually interested in light-weight robots – and maybe that’s what the field should be called – but we ended up deciding that the best way is to make inflatable robots and they’re inherently soft, so we got classified as “soft robotics.”

Can you also talk a little bit about the technological challenges that you have to face when you build inflatable robots?

Many people worry that an inflatable robot is too weak to do anything useful. So, one of the things we tested was: can they lift heavy loads? And yes, they can lift 10 or 15 kilograms and that’s enough for a lot of the care tasks that we want to do. If you don’t use a robot in the configuration of an arm of a humanoid and, instead, put the inflatable part underneath something, you can lift a larger mass. Inflatable devices are used to lift cars and buildings, so they can be very, very strong.

The second fear with inflatable robots is, if you puncture it, it will deflate and be useless. It turns out that the suits used for space walks, on the International Space Station, are also inflatable robots. They’re designed to self-seal if they’re damaged, so they don’t deflate immediately; there are techniques to help inflatable robots survive when they’re punctured, they can have compartments. So, puncturing an inflatable robot is not a big problem. In Big Hero 6, the robot repairs itself after it has several holes in it.

Yes, exactly – with scotch tape.

Yes.

Can you say a little bit more about energy efficiency? Is there a lot of energy needed in order to keep the pressure up in the robot or is that quite easy to do?

I don’t think it’s a lot of energy. It all depends on how much leakage you have. If you have a system that’s continually leaking and inflating, it may run up your energy bill. But if you have a situation where the structure doesn’t leak very much, and you only have to add a little air once in a while, that’s not a big problem.

You’ve already talked a little bit about possible applications for such types of robots. Do you have any other applications, outside of care-taking, in mind?

Robots that are toys and interact with children need to be very, very safe so I think soft, or lightweight, robots have an application there. Basically, [in] any kind of situation where you’re interacting with people, we need a high amount of safety.

Do you use any special sensors for your inflatable robots? Maybe a stretchable, bendable sensor, or do you use off-the-shelf sensors?

I think when you have a robot that’s not rigid, you tend to rely more on vision and external sensing. A rigid model can rely on sensors in the joints to achieve accuracy, but with the soft robots, you tend to have to look at where your hand is and where the target is in order to figure out: are you reaching the target accurately?

Closely connected to that, the control approach might be different as well, right? Or do you employ the same techniques that are used for a rigid robot?

I think the control approach may well be different. You can think of it as a much more flexible or complicated dynamic, essentially everything bends. And that means you have to be a little more cautious and use lower “control gains” or “stiffnesses” in order to move the robot around. So I think there need to be slightly different techniques, both in sensing and in control.

Your name is well-known in the field of machine learning too. I was wondering if you have any plans to link your expertise there to soft robots. Do you see the soft body as an advantage there?

We have already used learning for the “kinematics” of the robot; in other words, how to reach accurately, even though the parts of the robot are soft and bendy. The big surprise is that, when you start building complicated metal robots, hard robots, they also bend if they’re complicated enough – like a humanoid robot – because they have so many joints and there is play in them. So some of the techniques that we originally designed for soft robots are actually turning out to be useful for learning with the metal robots.

In the movie, Hero builds rigid body parts for Baymax to enable it to fly around and to fight. Do you think that would make sense in real-life? And, if so, what applications could this have?

I think it’s a very good idea to have robots that can change modes. In this case, Baymax put on a hard outer shell in order to become stiff, and I think that makes a lot of sense. If you have a service or house robot, and it needs to be strong, it could use tools or put on a suit in the same way that people use tools. I think it’s a very cost effective way to get robots to do a wide range of things.

Do you also see a use for such types of robots outside the house, for disaster relief or for military use, for example? Because I would assume that a soft robot doesn’t have to model its environment in order to move around in it. Would that be a good application?

It depends on what kind of disaster you’re imagining. If you have an earthquake, for example, and a lot of rubble, you need small, agile robots to find victims, and very strong robots to dig them out. So maybe we’d have more specialized robots, say, in Japan preparing for an earthquake. If it’s a disaster that involves a lot of people getting sick, like the Ebola situation, then the soft robots may make more sense. They can be made very cheaply because we are using techniques similar to the ones used to make clothes, so we could even have disposable robots rather than trying to clean them. So, in the United States, when the Ebola problem was much greater a few months ago, there was some discussion about what kind of robots we should develop and soft robots was a possible answer.

What about using such types of robots for exo-planetary exploration, since, in space travel, weight and mass are a big issues?

Sure. Did you know we use inflatable landing systems to land probes on Mars? So, that’s already an example. If you’re going to build a habitat that people live in, it would probably be inflatable, if you want to deploy very large structures in space. Currently, we use unfolding wing-like things that are quite complicated. It’s possible that inflating them would be a better way to go – to make very large solar panels or antennas.

You have a project called “Build Baymax”. Can you tell us a little bit more about that?

Yes. Of course, it’s inspired by the movie. There are two parts to the project. One is building the body: Can we build something with the capabilities of the robots in the movie? The second part is building the brain: Can we build robots that are capable of having the artificial intelligence that Baymax showed in the movie? We have groups to pursue those two targets, building the body and building the brain.

The movie is – I think – really inspiring, for adults as well as for kids. Because it talks about being a good scientist and being curious about things. So, if you were to give advice to kids who may be interested in soft robotics, what good sources are there for inspiration? What kind of skills does someone need to join the next generation of soft roboticists?

I would, of course, emphasize that studying mathematics and science is very important. But, I also think it’s possible for children to build soft robots, because it’s like making clothes and children can do it at home. If you want to build a metal robot, you typically need access to parts. With soft robots, it’s like building a kite and you can do that in your home. You can have some fun and get some experience. In the United States, we have a term, “home economics,” which is about teaching people to sew and things like that. Soft robotics could make home economics popular again.

Further reading on soft robotics:

Chris Atkeson’s webpage

Build Baymax website

Robosoft – An EU research community around soft robotics

If you liked this article, you may also be interested in:

- While most robots are either geek or jock, CHAPPiE is a lesson in sexy

- Robot love: Spike Jonze’s new sci-fi film ‘Her’ may be closer to reality than you think

- Automata: The new “sci-fi” blockbuster set to put robot ethics under a spotlight

- Ability to self-repair isn’t the same as consciousness: Analyzing Automata from a tech standpoint

See all the latest robotics news on Robohub, or sign up for our weekly newsletter.

tags: c-Arts-Entertainment, Carnegie Mellon, cx-Research-Innovation, healthcare, robohub focus on arts and entertainment, robohub focus on soft robotics, soft robotics